Automatic Girth Welder

Our AGW series automatic girth welder represents the most advanced tank welding technology today. The system adopts innovative dual AC drive system and precision laser tracking technology, which can significantly improve the welding efficiency by 40% and make the construction of large storage tanks more efficient and reliable.

WUXI ABK stands at the forefront of automatic girth welding technology, with 15 years of dedicated R&D experience serving global clients in petroleum, chemical, and energy industries. Our AGW series represents the pinnacle of tank welding innovation, combining advanced automation with precision engineering to deliver exceptional results across diverse industrial applications.

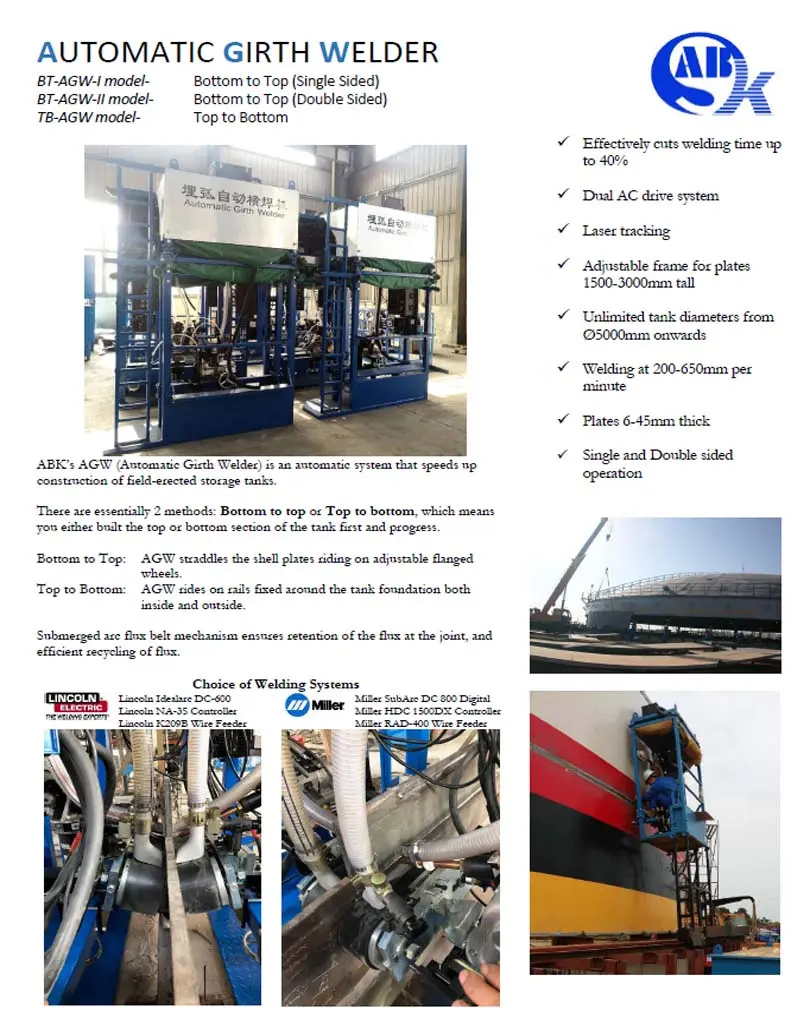

The AGW system features a revolutionary dual AC drive system paired with military-grade laser tracking technology, achieving ±0.5mm weld seam accuracy while increasing productivity by 40%. Its adaptable frame design accommodates plate heights from 1500-3000mm and tank diameters starting from φ5000mm with no upper limit. Operators benefit from adjustable welding speeds of 200-650mm/min, handling material thicknesses of 6-45mm in both single and double-sided operation modes.

In critical infrastructure projects, our equipment demonstrates unparalleled performance. It efficiently handles girth welding for 100,000m³ strategic petroleum reserve tanks, precisely joins 9% nickel steel in LNG cryogenic applications, and maintains perfect alignment when welding corrosion-resistant linings for chemical storage tanks. The system’s versatility extends to environmental and power industry applications for large container fabrication.

Two intelligent operation modes adapt to different construction requirements:

-

Bottom-Up Mode utilizes precision flange wheels for conventional tank construction

-

Top-Down Mode employs a track system for floating roof tank fabrication

Key technological advantages include a modular design for rapid on-site assembly, full compliance with ASME Section VIII standards, and an intelligent control system that memorizes optimal welding parameters for one-touch operation. Military-spec components ensure reliable performance in demanding environments.

WUXI ABK provides comprehensive support including customized process engineering, operator training, and 24/7 technical assistance. Our solutions deliver measurable value through:

✓ 30% reduction in project timelines

✓ 5-year warranty on critical components

✓ Global spare parts availability

✓ Certified welding quality meeting international standards

Technical Specifications:

-

Welding Speed: 200-650mm/min (stepless adjustment)

-

Plate Thickness Range: 6-45mm

-

Positioning Accuracy: ±0.5mm

-

Power Requirements: 380V/50Hz (custom configurations available)

-

Environmental Rating: IP54 protection

Wuxi ABK Machinery Co.Ltd is a professional adjustable welding rotator China manufacturer. And we can also provide our clients around the world with many other products including special welding rotator, wind tower production line, H beam welding line, pipe welding equipment, CNC cutting machine, grinding machine, roll forming machine, plate bending machine, etc. We have obtained ISO and CE certification, and we also offer OEM service. Our products have been well received by customers from many countries, such as Spain, India, Germany, South Africa, Brazil, Chile, Argentina, Russia, Italy, France, Vietnam, and more. If you’re interested in our adjustable welding rotator, please don’t hesitate to contact us whenever you want.