Schweißer-Positionierer

Der Schweißpositionierer von WUXI ABK bietet eine präzise Rotation (0,1-2 U/min) und Neigung (0-135°) für die Schwerindustrie. Sein frequenzumrichtergesteuerter Antrieb sorgt für eine gleichmäßige Geschwindigkeitsregelung, während die leitfähige Welle ein Verdrehen der Kabel verhindert. Die spannungsfreie Stahlkonstruktion hält Lasten von bis zu 5.000 kg stand und ist damit ideal für Druckbehälter, Windtürme und Schiffskomponenten. Mit Schneckengetrieben und zwei Halbkreisgetrieben sorgt dieser industrietaugliche Positionierer für Genauigkeit bei anspruchsvollen Schweißanwendungen.

WUXI ABK Heavy-Duty Welding Positioner is designed for precision industrial welding applications including pressure vessel fabrication, structural steel welding, and pipeline girth welding.

The positioner features a heavy-duty worktable with 6 T-Slot clamping system capable of securing workpieces up to 2,000kg, making it suitable for wind tower fabrication. It offers 360° servo-driven rotation with adjustable speed from 0.1 to 1.2 RPM, equipped with conducting slip rings for tangle-free operation. Options include explosion-proof (ATEX Zone 1) and water-cooled table configurations for specialized applications.

The precision drive system combines an AC motor with planetary gear reducer to achieve ±0.5° positioning accuracy. A cycloidal-worm tilting mechanism provides 0-135° tilt range for complex weld angles. The Siemens PLC control system with HMI touchscreen includes over 100 preset welding programs and is compatible with robotic welding cells.

Customization options include:

-

Load capacity from 500kg to 5,000kg for shipbuilding components

-

Table diameters ranging from 800mm to 3,000mm

-

CNC synchronization capability for automated production lines

Technische Parameter

| Modell | ABK-WP500 | ABK-WP2000 |

| Maximale Belastung | 500kg | 2.000kg |

| Drehung | 0,1-2 UMDREHUNGEN PRO MINUTE | 0,05-1 UMDREHUNGEN PRO MINUTE |

| Neigungswinkel | 0-90° | 0-135° |

| Strom | 3kW |

WUXI ABK Welding Positioner Product Introduction

Our welding positioner is engineered for demanding industrial applications across multiple sectors. In heavy equipment manufacturing, it handles excavator booms and crane segments with precision. The energy sector utilizes this system for wind turbine flanges and pressure vessel fabrication, while transportation applications include rail bogies and shipbuilding components.

The positioner features advanced variable speed control through a frequency conversion drive system, offering smooth speed adjustment from 0.1 to 2 RPM with continuous regulation. This stepless speed transition eliminates gear shifting while maintaining a low-maintenance design that reduces operational costs.

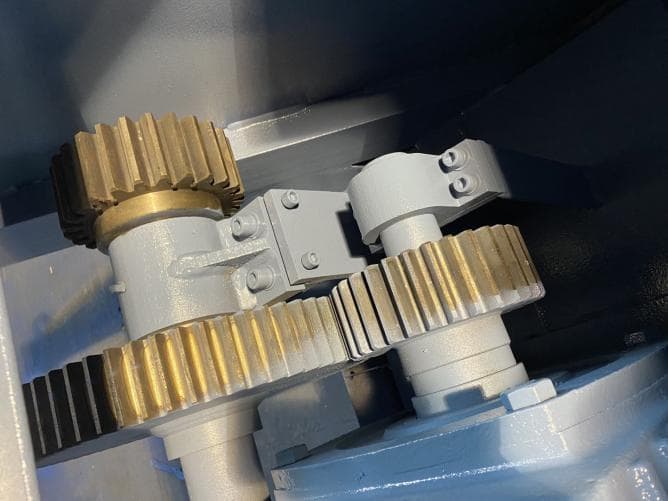

Precision movement is achieved through a dual semicircular gear system on the output shaft combined with a worm gear reducer, providing stable tilting across a 0-135° range. The integrated current conduction system features a rotary electrical interface that connects directly to the worktable, enabling direct current transmission through the conductive shaft to prevent cable twisting during rotation.

Built for heavy-duty performance, the positioner utilizes a box-type base constructed from Q235-A steel with stress-relieved annealing treatment. Precision machined surfaces ensure dimensional stability under loads up to 5,000kg, making it suitable for the most demanding welding applications.

Key features include:

-

Industry-proven durability for continuous operation

-

Precision movement control for complex weld paths

-

Integrated power transmission system

-

Heavy-duty construction for maximum load capacity

This welding positioner is designed to enhance productivity and quality in fabrication processes while reducing operator fatigue and maintenance requirements. The robust construction and precision components ensure reliable performance in industrial manufacturing environments.

Technische Parameter des Schweißpositionierers der Serie HBJ:

| Modell | HBJ-01 | HBJ-03 | HBJ-06 | HJB-12 | HBJ-30 | HBJ-50 | HBJ-100 | |

| Nenntragfähigkeit (kg) | 100 | 300 | 600 | 1200 | 3000 | 5000 | 10000 | |

| Drehgeschwindigkeit (U/min) | 0.4-4 | 0.1-1 | 0.09-0.9 | 0.05-0.5 | 0.05-0.5 | 0.05-0.5 | 0.05-0.2 | |

| Überdrehzahl (U/min) | Griff | 1.1 | 0.67 | 0.23 | 0.14 | 0.14 | ||

| Durchmesser des Arbeitstisches (mm) | ¢400 | ¢600 | ¢1000 | ¢1200 | ¢1400 | ¢1500 | ¢2000 | |

| Wendewinkel (°) | 0-120 | 0-90 | 0-90 | 0-120 | ||||

| Motorleistung (KW) | Wenden | 0.06 | 0.37 | 0.75 | 1.1 | 1.5 | 3 | 5.5 |

| Umkehrung | 0.75 | 2.2 | 1.5 | 3 | 5.5 | |||

| Drehzahlregelung Typ | Stufenlose Frequenzumwandlung | |||||||

| Max. Schwerkraftabstand (mm) | 100 | 100 | 100 | 150 | 200 | 300 | 400 | |

| Max. Exzentrizität (mm) | 150 | 150 | 150 | 200 | 200 | 300 | 400 | |

| Max. Drehdurchmesser bei 90° Überschlag (mm) | ¢600 | ¢800 | ¢1500 | ¢2050 | ¢2100 | ¢2500 | ¢3240 | |

1. Großwälzlager

Das Großwälzlager ist ein wichtiges lasttragendes Bauteil, das die relative Drehung zwischen Maschinenteilen ermöglicht und gleichzeitig Axial-, Radial- und Kippmomentkräfte aufnimmt. Seine kompakte und leichte Konstruktion aus hochfestem legiertem Stahl gewährleistet einen reibungslosen Betrieb mit hoher Präzision (±0,05° Drehgenauigkeit) und langer Lebensdauer. Zu den wichtigsten Konfigurationen gehören Befestigungsbohrungen, optionale Innen-/Außenverzahnungen, Schmieranschlüsse und Dichtungssysteme für erhöhte Zuverlässigkeit. Mit einem Durchmesserbereich von 300-5000 mm und einer Tragfähigkeit von bis zu 50.000 kN wird es häufig in Baumaschinen, Windturbinen, Kränen und militärischer Ausrüstung eingesetzt. Für spezielle Anwendungen sind Sonderausführungen erhältlich.

- Getriebe

1). Rückwärtsgang

Im Allgemeinen beträgt der Drehwinkel der Drehvorrichtung 0°bis 90°. Die Funktion der Verschiebung wird durch Drehen des Tisches erreicht.

2). Rückwärtsgang

Zahnräder sind verzahnte mechanische Komponenten, die durch das Ineinandergreifen mit anderen Getriebeelementen wie Zahnstangen, Schnecken oder zusätzlichen Zahnrädern ein Drehmoment übertragen. Sie ermöglichen eine präzise Steuerung der Kraftübertragung durch Änderung des Drehzahl-/Drehmomentverhältnisses, Umlenkung von Bewegungswegen und Umwandlung von Bewegungsarten (z. B. rotierend in linear). Ihre ineinander greifende Verzahnung sorgt für eine zuverlässige Kraftübertragung und ermöglicht gleichzeitig einen anpassbaren mechanischen Vorteil in verschiedenen industriellen Anwendungen.

3. die Reduktion

Untersetzungsgetriebe sind mechanische Kraftübertragungsvorrichtungen, die mit Hilfe von Präzisionsgetrieben die Eingangsdrehzahl reduzieren und gleichzeitig das Ausgangsdrehmoment proportional erhöhen, wobei das Ausgangsdrehmoment das Produkt aus Motordrehmoment und Getriebeübersetzung ist (ohne die Nennkapazität des Getriebes zu überschreiten). Diese Systeme verringern gleichzeitig das Trägheitsmoment der Last um das Quadrat des Untersetzungsverhältnisses und ermöglichen eine optimierte Leistungsumwandlung für verschiedene industrielle Anwendungen durch einen effizienten Getriebeeingriff.

Schweißen Drehscheibe Leitlinien für die Instandhaltung

Grundlegende Wartungsinhalte

Tägliche Wartung - Reinigung der Schweißschlacke, Überprüfung der Schmierung und der elektrischen Sicherheit.

Regelmäßige Wartung - Schrauben nachziehen, Getriebemechanismus prüfen und Sicherheitsfunktion testen.

Umfassende Wartung - jährlicher Austausch verschlissener Teile, Nachschmierung und Systemkalibrierung

Fehlerfrühwarnung - Sofortiges Anhalten, wenn abnormale Geräusche/ungleichmäßige Drehung auftreten.

Wert erhalten

- Verlängern Sie die Lebensdauer von Geräten um mehr als 30%

- Verringerung plötzlicher Ausfallzeiten

- Gewährleisten Sie die Stabilität der Schweißgenauigkeit.

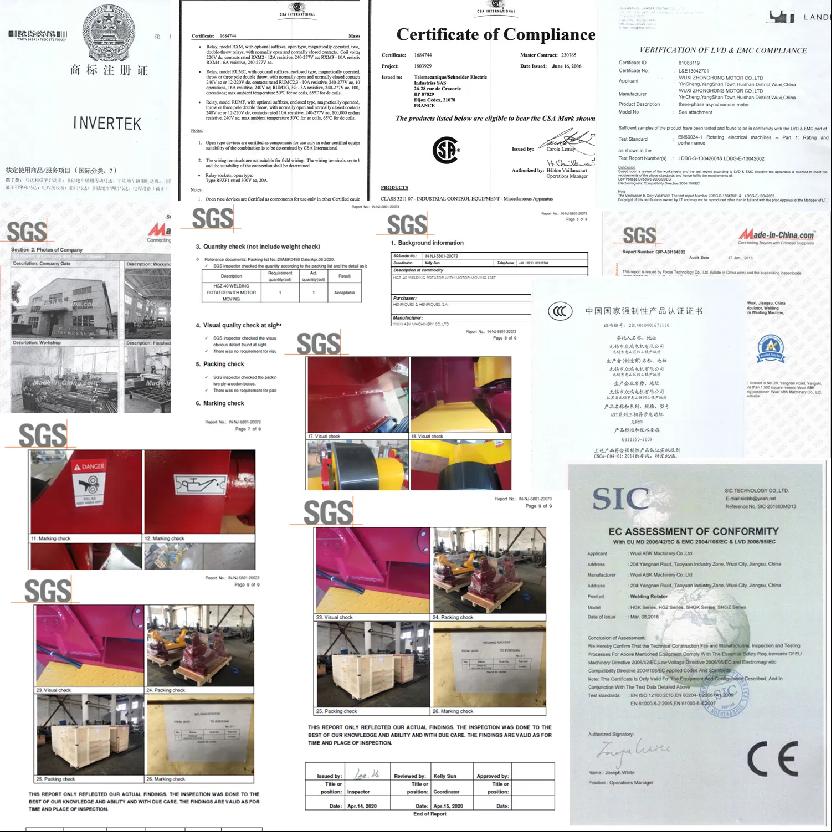

Produktzertifizierung

Steigen Sie mit unseren innovativen Lösungen in die Zukunft der Schweißtechnik ein.

Von automatisierten Prozessen bis hin zu intuitiven Steuerungen stehen unsere Produkte an der Spitze der Innovation und geben Ihnen die Werkzeuge an die Hand, die Sie brauchen, um auf dem heutigen wettbewerbsorientierten Markt die Nase vorn zu haben!

Wuxi ABK Machinery Co.Ltd ist ein professioneller Hersteller von Schweißrotatoren in China. Und unser Schweißrotator umfasst hauptsächlich Standard-Schweißrotator, einstellbarer Schweißrotator und spezieller Schweißrotator. Wir können unseren Kunden auf der ganzen Welt auch viele andere Produkte anbieten, einschließlich Schweißdrehtisch, Pfahlschweißmaschine, Windturm-Produktionslinie, H-Träger-Schweißlinie, Rohrschweißausrüstung, CNC-Schneidemaschine, Schleifmaschine, Walzprofiliermaschine, Blechbiegemaschine, etc. Wir haben die ISO- und CE-Zertifizierung erhalten und bieten auch OEM-Service an.