CNC-Laserschneidmaschine

WUXI ABK CNC-Faserlaserschneidmaschine bietet Präzisionsmetallschneiden mit fortschrittlicher 500W/1000W Faserlasertechnologie. Ausgestattet mit HIWIN-Führungen, Panasonic-Servos und dem deutschen Befo-Steuerungssystem, gewährleistet er eine schnelle, energieeffiziente Bearbeitung von Stahl, Aluminium und Kupfer. Die integrierte Staubabsaugung sorgt für einen sauberen Betrieb. Ideal für die Automobil-, Luft- und Raumfahrtindustrie sowie für die Blechbearbeitung.

Principle of Operation

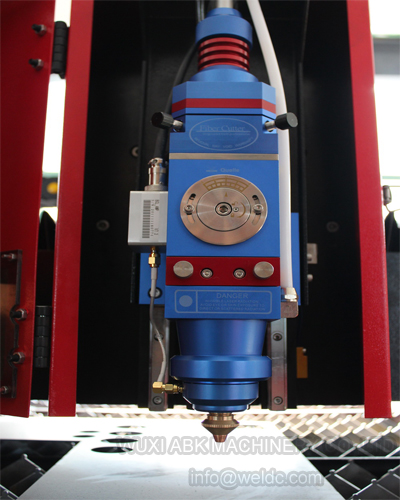

The CNC fiber laser cutting machine utilizes advanced fiber laser technology to deliver high-precision, high-efficiency metal cutting. The laser generator produces a high-energy laser beam, which is transmitted through a fiber optic cable to the cutting head. The precision focusing lens group concentrates the laser beam into a micron-level focal point (approximately 0.1mm in diameter), generating an instantaneous temperature exceeding 10,000℃. This extreme heat causes the material to vaporize instantly, while a high-pressure auxiliary gas (O₂/N₂) blows away molten residue, ensuring clean, smooth cuts. An integrated dust removal system efficiently eliminates cutting debris in real time, maintaining a clean working environment and prolonging machine life.

Core Configuration

1. Laser System

-

Fiber laser source: Equipped with a Wuhan Ruike 500W pulsed fiber laser (optional 1000W high-power laser for thicker materials).

-

Laser wavelength: 1070nm, ensuring optimal absorption by metal materials.

-

Photoelectric conversion efficiency: Over 30%, reducing energy consumption and operational costs.

-

Beam quality monitoring: Includes a high-precision beam quality analyzer (imported from the UK) for consistent cutting performance.

2. Transmission System

-

Linear guide rails: Taiwan HIWIN high-rigidity silver rails (20mm), ensuring smooth and stable motion.

-

Servo motors: Original Panasonic servo motors (X-axis: 1000W, Y-axis: 3000W) for high-speed, high-torque movement.

-

Ball screws: C3-grade precision ball screws (32mm diameter), minimizing backlash and enhancing positioning accuracy.

3. Control System

-

Motion control: Germany Befo multi-axis motion control card, ensuring ultra-precise cutting path execution.

-

Software compatibility: Supports DXF/DWG/AI file formats for seamless CAD/CAM integration.

-

Cutting parameter database: Real-time adjustment of laser power, cutting speed, and gas pressure for optimized performance across different materials.

Die wichtigsten Vorteile

-

High-speed cutting: Optimized fiber laser technology enables rapid processing of stainless steel, carbon steel, aluminum, and copper.

-

Energy-efficient operation: 30%+ photoelectric conversion efficiency reduces power consumption.

-

Low maintenance: Fiber laser cutting systems require minimal upkeep compared to CO₂ lasers.

-

Automated dust removal: Integrated extraction system ensures a clean workspace and extends machine longevity.

This CNC laser cutting machine is ideal for industries requiring precision metal fabrication, including automotive, aerospace, electronics, and sheet metal processing. With its high-power fiber laser source, robust transmission system, and intelligent control software, it delivers superior cutting accuracy, efficiency, and reliability.

Technical parameter

| Project | Specifications | Superiority |

| Working width | 1500×3000mm | Support customization 2000×4000mm |

| Positioning accuracy | ±0,02 mm | Laser interferometer calibration |

| Cutting accuracy | ≤±0.08mm | Superior to industry standards |

| Reproduzierbarkeit | ±0.01mm | Satisfy precision machining |

| Maximum acceleration | 1.5G | Shorten the idle time |

Main Components

| Komponente | Brief Introduction | Manufacturer Info |

| Laser Device | China Wuhan Optical Valley Raycus 500W fiber laser | Wuhan Raycus |

| Optical system | Wuhan Raycus laser power | England |

| Laser Power | 600W pulse laser system | Wuhan Raycus |

| Cutting Head | Professional high precision head | ABK Technology |

| Cooling System | Overtemperature protection, temperature stability±0.5℃, environmental protection two-cycle water-cooling machine, titanium alloy evaporation tube control, 2P all in one cooling tank | ABK Technology |

| Mechanical Drive System | High precision ball screw; original Panasonic Servo Motor; Taiwan HIWIN Guide Rail | HIWIN, Taiwan |

| Tracking & Sensing System | High precision self sensing; accuracy ±0.1mm | ABK Technology |

| Working Area | 1500×3000mm | Made in China |

| Computing System | IPC | Made in China |

| X Axis Servo Unit | 1000W single driven | Panasonic |

| Y Axis Servo Unit | 3000W single driven | Panasonic |

| Limit Switch | NPN | Omron |

| Cutting Software | V2.0 | ABK Technology |

| I/O Card | 32 points | Googol, Shenzhen |

| Working Platform | Gantry type | ABK Technology |

Main Indexes of QY-LCF500 Laser Cutting Machine

| Laser Wavelength | 1070nm |

| Maximum Laser Output Average Power | 500W |

| Laser Repeated Frequency | CW |

| Power Instability | =<2% |

| Minimum Line Cutting | 0.2mm (for material below 0.4mm) |

| Maximum Cutting Speed | =<15m/min (depends on different material) |

| Maximale Schnittdicke | =<5mm (carbon steel) =<4mm (stainless steel) |

| Continuous Operating Time | >=20 hours |

| Maximum Cutting Breath | 3000mm*1500mm |

| Working Platform Accuracy | ±0.08mm |

| Repeat Location Accuracy | ±0,02 mm |

| Stromversorgung | Three-phase five line exchange 380V±5%, 50Hz±1% |

| Software | Phase selecting provided |

| Weight of the Machine (Estimated) | 4200kg |

Equipment Cutting Indexes(This is only for your reference. Speed may be different as for different figure. It should be based on the practical test results.)

| Material | Thickness (mm) | Speed (mm/s) | Auxiliary Gas | Bemerkung |

| Rostfreier Stahl | 0.3 | 240 | O2 | Limiting Velocity |

| Rostfreier Stahl | 0.5 | 200 | O2 | Limiting Velocity |

| Rostfreier Stahl | 1 | 180 | O2 | Limiting Velocity |

| Rostfreier Stahl | 2 | 110 | O2 | Limiting Velocity |

| Rostfreier Stahl | 3 | 45 | O2 | Limiting Velocity |

| Rostfreier Stahl | 4 | 24 | O2 | Limiting Velocity |

| Rostfreier Stahl | 5 | 20 | O2 | Limiting Velocity |

| Rostfreier Stahl | 0.3 | 150 | N2 | Limiting Velocity |

| Rostfreier Stahl | 0.5 | 130 | N2 | Limiting Velocity |

| Rostfreier Stahl | 1 | 100 | N2 | Limiting Velocity |

| Rostfreier Stahl | 1.2 | 90 | N2 | Limiting Velocity |

| Rostfreier Stahl | 1.5 | 60 | N2 | Limiting Velocity |

| Rostfreier Stahl | 2 | 40 | N2 | Limiting Velocity |

| Rostfreier Stahl | 2.5 | 12 | N2 | Limiting Velocity |

| Kohlenstoffstahl | 1 | 170 | O2 | Limiting Velocity |

| Kohlenstoffstahl | 2 | 80 | O2 | Limiting Velocity |

| Kohlenstoffstahl | 3 | 40 | O2 | Limiting Velocity |

| Kohlenstoffstahl | 4 | 20 | O2 | Limiting Velocity |

| Kohlenstoffstahl | 5 | 15 | O2 | Limiting Velocity |

| Kohlenstoffstahl | 6 | 10 | O2 | Limiting Velocity |

| Aluminium Sheet | 1 | 80 | O2 | Limiting Velocity |

Accessories and Specifications

| Item | Quantity | Bemerkung |

| Spezifikationen | 1 piece | |

| Protective Lens | 5 pieces | For free |

| Spray Nozzle | 2 pieces | For free |

| Inner Hexagon Wrench | 1 set | For free |

| Professional Polishing Paper | 1 piece | For free |

|

Terms of the transaction 1. Price description l The product quotation includes 17% VAT (special VAT invoice can be issued). l EXW (optional CIP/DDP terms) 2. Delivery cycle l Standard model: delivered within 30 working days after signing the contract. l Customized model: 45-60 working days (subject to contract confirmation) 3. Payment types/methods l 30% down payment (contract signing) l 50% of the progress payment (before the equipment leaves the factory) l 20% of the balance (after acceptance) Quality assurance (control) system ◇ Whole process quality control Raw materials: Baowu/Shougang high-quality steel is adopted. Production process: implementing ISO9001 quality management system. Ex-factory inspection: 72 hours continuous operation test ◇ Warranty clause The warranty of the whole machine is 12 months (24 months for laser) List of wearing parts: protective lenses/nozzles/filter elements, etc. Full-cycle service system 1. Pre-sales support ✓ Free technical consultation Provide process plan design Material trial cutting service (limited to 3 times) Suggestions on workshop layout planning ✓ value added service Professional selection software support Return on investment analysis report Comparative evaluation of similar equipment Installation training Standard service package: ▶ Installation of equipment in place (compliance site shall be provided by customers) ▶ Mechanical/electrical system debugging ▶ 5-day systematic training (2-3 people) l Safe operation of laser (OSHA standard) l Software programming practice l Daily maintenance specification l Common fault handling Optional upgrade service: ▶ Integrated debugging of production line (additional quotation required) ▶ Multi-shift training (+3 days) Acceptance process ① Factory Pre-acceptance (FAT) ② On-site installation and debugging (SAT) ③ 72-hour continuous production test ④ Final acceptance document signing After-sales service Quick response: Ø 400 service hotline (7×24 hours) Ø Technical response within 2 hours Ø 24-hour engineer presence (domestic) Service content: Ø Annual preventive maintenance (4 times) Ø Remote diagnosis support Ø Rapid supply of spare parts (standing 100+ categories) |