Rotador de soldadura especial

Rotador de soldadura especial WUXI ABK proporciona uma rotação precisa para aplicações de soldadura complexas. Com Rotação contínua de 360 e Precisão de ±0,5, este posicionador para trabalhos pesados pegas 5-50 toneladas cargas. Ideal para fabrico de recipientes sob pressão e soldadura de aço estrutural, inclui Controlos PLC e rolos antiderrapantes. Certificação CE/ISO com Garantia de 24 meses.

Special Welding Rotator | Heavy-Duty 360° Positioning | Customizable for Industrial Welding Precise rotation (0.1 mm) | Super load (50t) | Intelligent control (PLC/HMI)

Core parameter list

| Parameter term | Technical specifications |

| Loading capacity | 5-50 tons (Can be customized) |

| Rotational accuracy | ±0.1mm/m(Laser calibration) |

| Speed range | 0.05-2 RPM(Stepless speed regulation) |

| Drive system | Double servo motor+planetary reducer |

| Applicable workpiece diameter | 300mm-10m(Support non-standard design) |

| Power requirement | 380V/50Hz(Optional explosion-proof motor) |

| Control mode | Touch screen PLC (preset 20 welding programs) |

✅ Precise rotation (±0.1 mm) | ✅ Super load (50T) | ✅ Intelligent control (PLC/HMI)

High rigidity structure

Box-shaped steel frame+polyurethane anti-skid roller, the deformation resistance is improved by 40%

To better meet customer needs, we offer a range of specialized welding rotators including PU wheel rotators, hydraulic lift rotators, and fit-up rotators. These machines are ideal for pipelines, wind towers, pressure vessels, and small pipes.

We also provide custom design and manufacturing services to accommodate specific project requirements.

Motor & Maintenance Guidelines

O WUXI ABK Rotador de soldadura especial foi concebido para heavy-duty industrial applications, incluindo fabrico de recipientes sob pressão, produção de torres eólicase construção naval. Before operation, clean the rotator thoroughly and protect the high-strength rubber rollers from oil and high temperatures to prevent premature aging. A trained operator should handle maintenance to ensure optimal performance.

Lubrication & Care

-

Fill the precision speed reducer com Óleo de motor 30# before startup (use winter-grade oil below 0°C).

-

Substituir o óleo após o first 30 days, então a cada 500 horas de funcionamento or 6 months.

-

Nunca use the roller bed as a welding ground to avoid bearing damage—always use dedicated grounding clamps.

Porquê escolher a WUXI ABK?

Com Mais de 20 anos of expertise in self-aligning rotators, nós entregamos:

✓ 5-400 ton load capacity para automatização da soldadura industrial

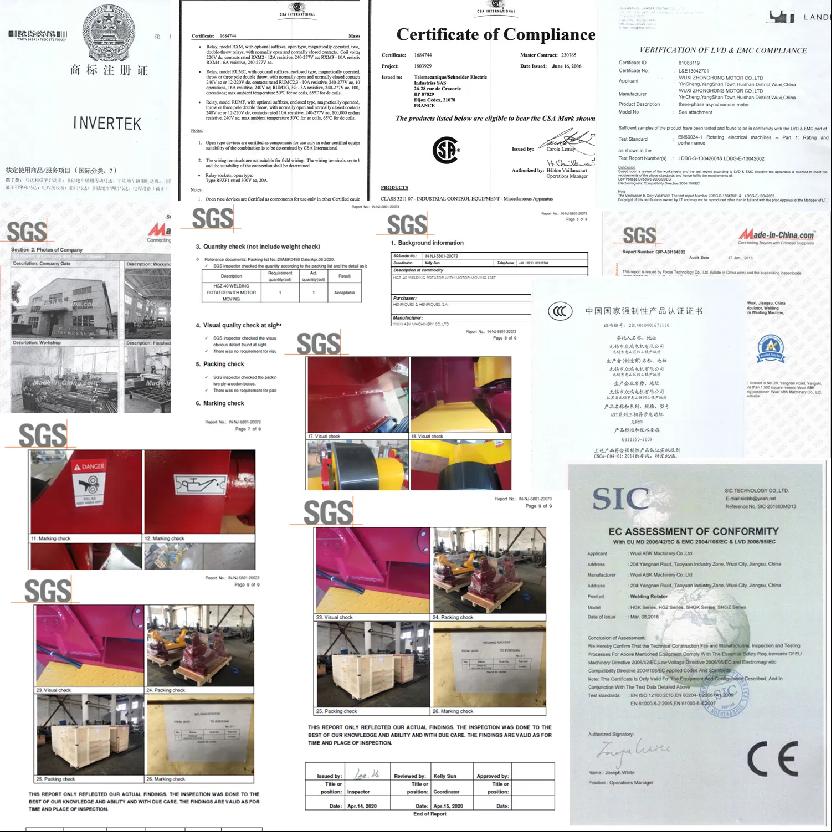

✓ Certificação CE e ISO designs, compliant with global safety standards

✓ Garantia de 1 ano com free wear parts replacement

✓ Suporte técnico 24/7 para soldadura de turbinas eólicas, construção offshoree fabrico em grande escala

Wuxi ABK Machinery Co.Ltd é um fabricante profissional de rotador de soldadura na China. E o nosso rotador de soldadura inclui principalmente rotador de soldadura padrão, rotador de soldadura ajustável, e rotador de soldadura especial. Nós também podemos fornecer aos nossos clientes em todo o mundo muitos outros produtos, incluindo mesa giratória de solda, máquina de solda de estaca, linha de produção de torre eólica, linha de solda de viga H, equipamento de solda de tubo, máquina de corte CNC, máquina de moagem, máquina perfiladeira, máquina dobradeira de placa, etc. Nós obtivemos certificação ISO e CE, e também oferecemos serviço OEM.