Welding Manipulator

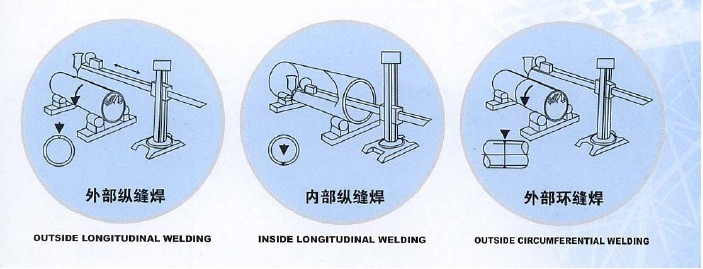

WUXI ABK Welding Manipulator delivers precision seam welding for boilers, pressure vessels and petrochemical applications. Featuring automated tracking and adjustable configurations, this industrial-grade system handles both longitudinal and circumferential welds with ±0.2mm accuracy. Optional flux recovery and monitoring systems enhance productivity. Ideal for heavy fabrication in metallurgical and energy sectors.

Technical Parameters of Welding Manipulator (Column Boom Manipulator):

| Model | LH8080 | LH4580 | LH5060 | LH3040 | LH1235 |

| Horizontal travel(mm) | 8000 | 4500 | 5000 | 3000 | 1200 |

| Vertical travel(mm) | 8000 | 8000 | 6000 | 4000 | 3500 |

| Rotating angle(mm) | ±180° | ±180° | ±180° | ±180° | Manual control ±360° |

| Rotating speed(m/min) | 0.12 | 0.12 | 0.12 | 0.12 | |

| Boom elevating speed(m/min) | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Boom forward speed(m/min) | 0.12-1.2 | 0.12-1.2 | 0.12-1.2 | 0.12-1.2 | 0.12-1.2 |

| Tablorward-backward speed(m/min) | 0.2-2 | 0.2-2 | 0.2-2 | 0.2-2 | Manual control |

| Table rail distance(mm) | 2700 | 2000 | 2000 | 1500 | 1000 |

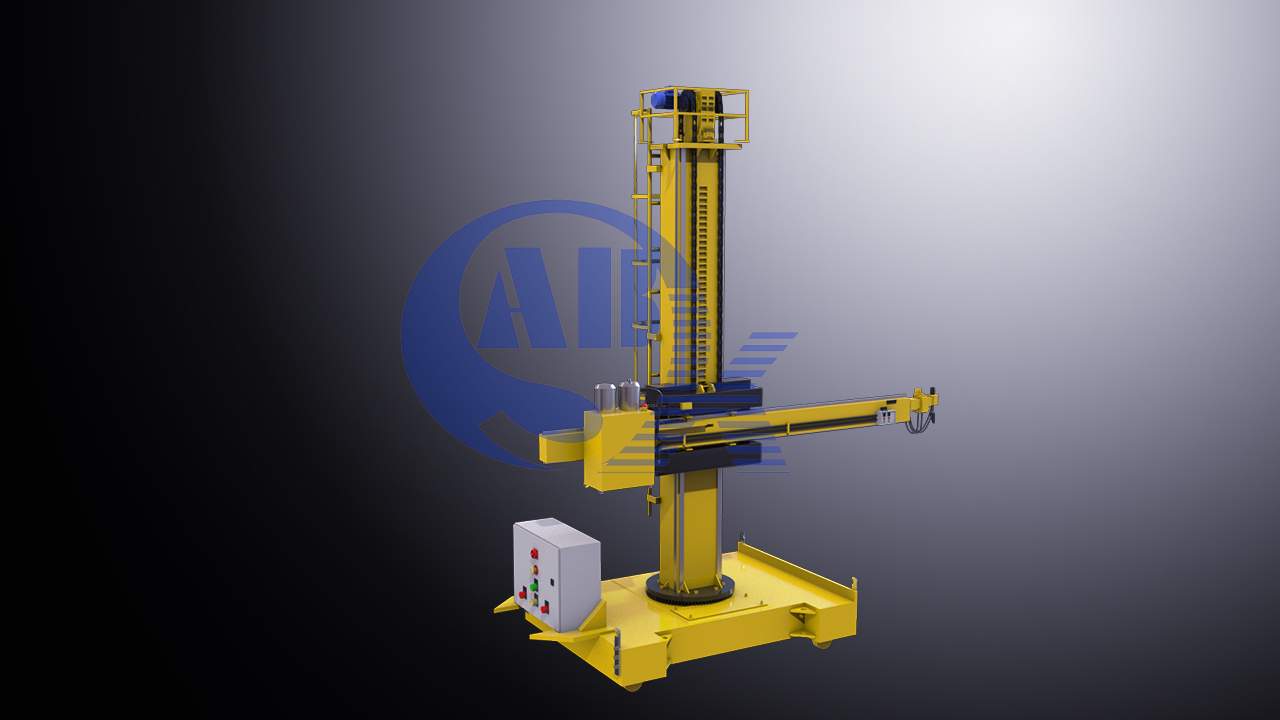

Main structure

Column+cross arm+guide seat+mobile trolley

Composition of a complete set

* Column

* Boom

* Base

* Saddle

* Lifting system

* Extension system

* Rotation system

* Rotation lock

* Moving and rotation type

* Anti drop

* Head corner

* Carriage on Boom

* Power-slides

* Control system

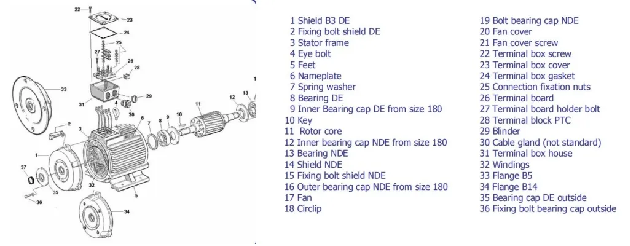

- Motor

Reducer

Reducer

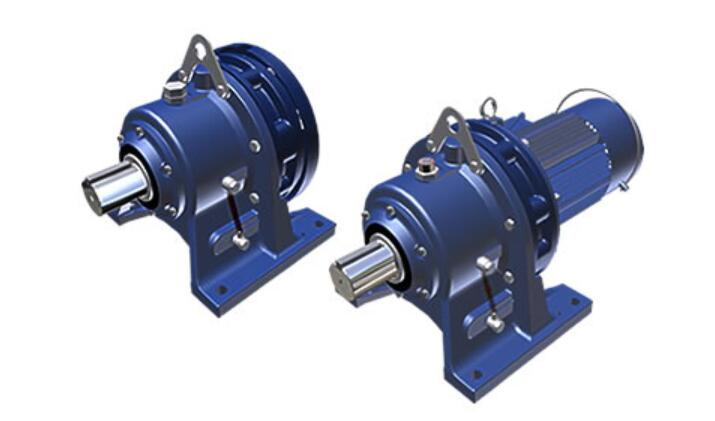

Planetary cycloid reducer is a new type of gear reduction mechanism with advanced design and novel structure, which applies the principle of planetary transmission and engages with cycloid pinwheel.In most cases, this reducer has replaced two-stage and three-stage ordinary cylindrical gear reducers and cylindrical worm reducers, and has been widely used in military industry, aerospace, metallurgy, mining, petroleum, chemical industry, ship, light industry, food, textile, printing and dyeing, pharmaceuticals, rubber, plastic, and hoisting and transportation.

Product characteristics:

- High transmission ratio.

- High transmission efficiency.

- Compact structure, small size and light weight.

- Less failures, long life.

- Smooth and reliable operation.

- Easy disassembly and repair.

- Strong overloading capacity, impact resistance, small inertia moment, suitable for frequent starting and positive and reverse operation.

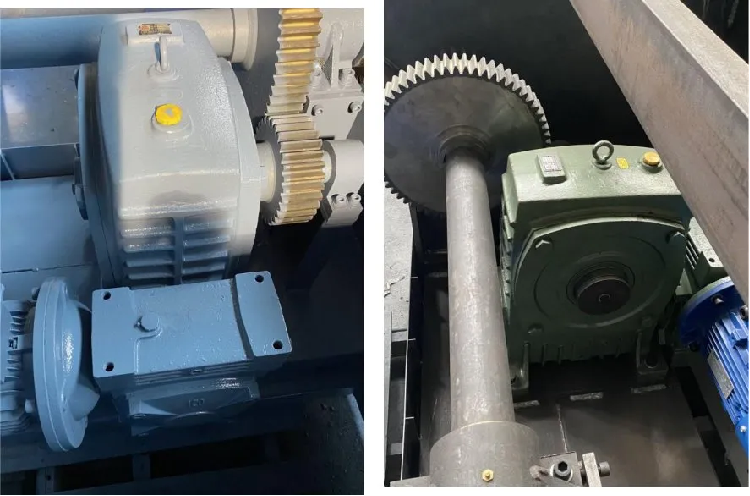

The reducer is a kind of power transmission mechanism, which uses the speed converter of gear to reduce the rotation number of motor to the required rotation number and obtain a structure with large torque.

Function of reducer:Reduce the speed and increase the output torque at the same time. The torque output ratio is multiplied by the motor output deceleration ratio, but it shall not exceed the rated torque of the reducer. At the same time, the inertia of the lo.ad is reduced to the square of the deceleration ratio.

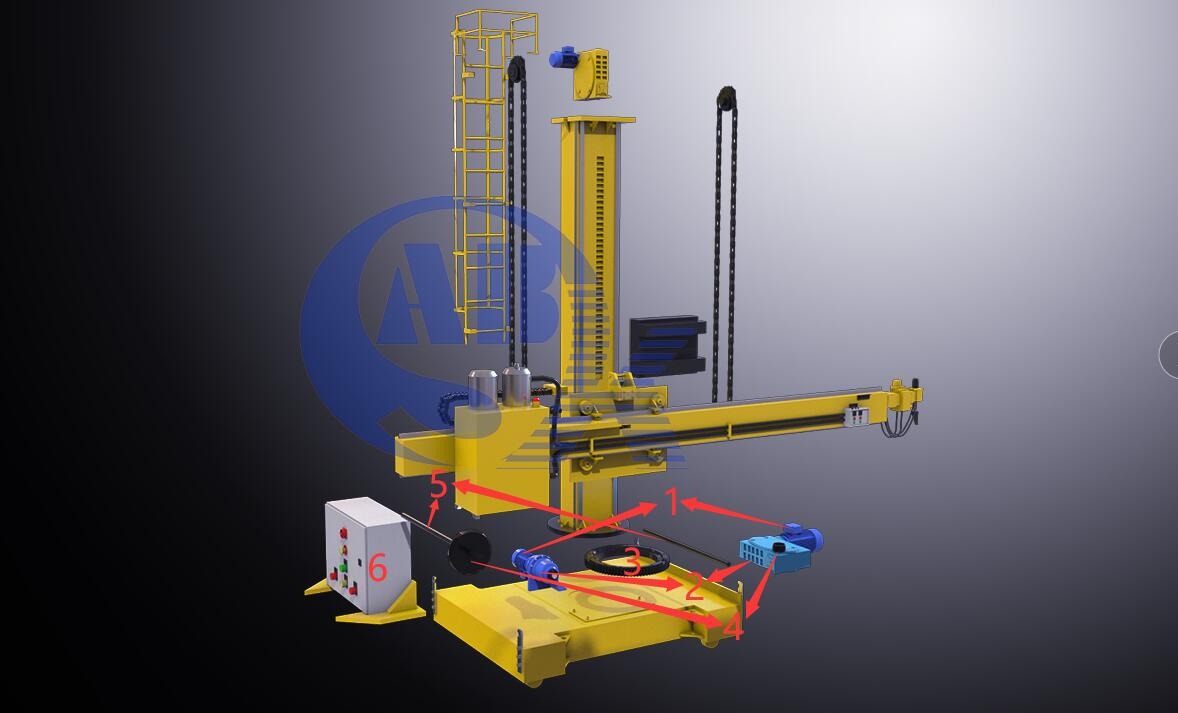

- Slewing bearing

Slewing bearing is the force basic element of machine, which requires relative rotation between all two parts and bears axial force, radial force and overturning moment at the same time.Its basic function is to use bolts to fix it on the upper and lower supports of mechanical equipment to transmit force and drive so as to realize the relative rotation between the two parts of mechanical equipment.Rotary support generally has installation holes, internal or external gears, lubrication holes and sealing devices. It has the characteristics of compact structure, light weight, good structural steel, smooth operation, high accuracy, safety and reliability.

Slewing bearing is a basic part of mechanical equipment and widely used in various industries of national economy. It is widely used in construction machinery, port machinery, metallurgical machinery, mining machinery, petroleum machinery, chemical machinery, medical equipment, ship machinery, light industrial machinery, environmental protection machinery, entertainment equipment, transportation machinery and military equipment. Swing supports are increasingly used in energy-saving and environmental protection projects, such as wind turbines that require a variety of precision pole swing support kits.

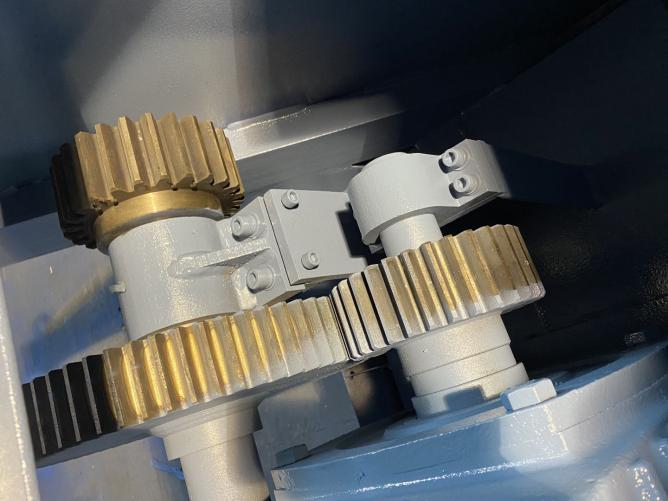

- Gear

Gear is a wheel like mechanical part which transmits the torque by the engagement of teeth. Through the transmission with other toothed mechanical parts (such as another gear, Dao rack and worm), the gear can change the speed and torque, change the direction of motion and change the form of motion.

- Axis

The transposition machine drives the rotation of internal gear through the rotation of shaft, and then drives the rotation of external gear, thus achieving the function of transpositio

WUXI ABK Welding Manipulator Product Introduction

As a pioneer in welding automation technology, WUXI ABK MACHINERY has developed industry-leading welding manipulator systems specifically engineered for storage tank fabrication, pressure vessel manufacturing, and heavy steel structure construction. Our welding column and boom systems incorporate patented technologies that deliver unmatched precision and reliability in demanding industrial applications.

Core Technology Advantages

The welding column boom features a high-strength box beam structure with precision stress-relief treatment, ensuring long-term stability for continuous operation. Our tank welding manipulator system integrates high-precision linear guideways and rack transmission mechanisms, achieving exceptional ±0.1mm/m operational stability – critical for large-diameter storage tank welding. The intelligent control system combines automatic seam tracking with real-time process monitoring, enhancing both welding quality and productivity by up to 40% compared to conventional methods.

Configuration Options for Diverse Applications

WUXI ABK offers comprehensive welding manipulator solutions:

-

Fixed welding manipulators: Compact, economical systems ideal for longitudinal seam welding in small-to-medium storage tanks

-

Fixed rotary configurations: Added column rotation functionality for multi-angle container welding operations

-

Mobile rotary tank manipulators: Omnidirectional movement and 360° rotation capabilities for large tank field construction

All models feature seamless integration with positioners, turntables, and other auxiliary welding equipment.

Enhanced Safety and Control

The system incorporates multiple protective features:

✓ Anti-fall self-locking mechanism with multi-stage limit switches

✓ Comprehensive electrical protections (overload/overcurrent/undervoltage/short circuit)

✓ User-friendly interface with visual control panel and handheld remote

✓ 200mm welding torch adjustment range for precise positioning

Advanced Customization Capabilities

Our welding column boom systems support various intelligent add-ons:

-

Flux recovery systems

-

Real-time weld monitoring modules

-

Automated parameter adjustment

-

Quality inspection interfaces

Proven Industry Performance

WUXI ABK welding manipulators have been successfully deployed in over 200 major projects across:

-

Oil storage tank farms

-

Chemical processing vessels

-

Power generation equipment

-

Offshore platform structures

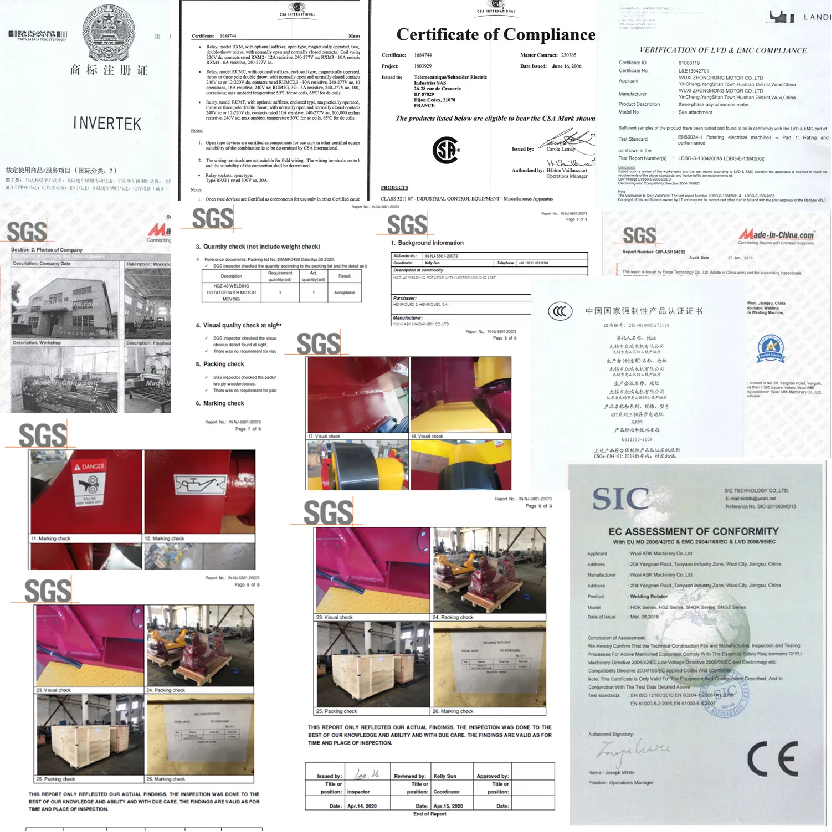

All systems comply with ASME, EN 1090, and other international standards.

Complete Service Package

We provide end-to-end solutions including:

-

Customized equipment selection

-

On-site installation and commissioning

-

Operator training programs

-

24/7 technical support

-

Regular maintenance services

Technical Specifications

-

Positioning Accuracy: ±0.1mm/m

-

Torch Adjustment: 200mm range

-

Travel Speed: 0.1-1.2m/min (variable)

-

Load Capacity: 500-5000kg (customizable)

-

Power Supply: 380V/50Hz (other voltages available)

Features of Welding Manipulator:

Structural advantage

V-shaped guide rail design-V-shaped guide rails with high bearing capacity are used for both upright posts and cross arms.

Dual security system

- The column is equipped with a brake motor to ensure stable positioning.

- Fracture protection of guide seat safety pin+column safety hole chain

Precision transmission system

- Cycloidal pin wheel+worm gear reducer

- Design of fully sealed oil-immersed lubrication and dust prevention

Intelligent control

- Stepless speed regulating converter (with fault detection and alarm function)

- Cross arm electric cross adjuster

- Pivot supporting base realizes synchronous welding of multiple workpieces

Industrial Applications

Our welding manipulator system is engineered for precision welding in critical industrial sectors, including boiler manufacturing, pressure vessel fabrication, petrochemical plant construction, and metallurgical processing. The equipment excels at both longitudinal seam welding and circumferential seam welding, handling both internal cylinder welding and external shell welding with equal proficiency. Its robust design makes it ideal for heavy industrial welding applications requiring consistent, high-quality results.

Configuration Options

The WUXI ABK welding manipulator offers flexible setups to match diverse production needs:

-

Fixed configuration for stable, high-precision welding tasks

-

Fixed rotary configuration for controlled rotational welding operations

-

Moving rotary configuration for dynamic, large-scale welding projects

Operating Conditions

To ensure optimal performance, the welding manipulator operates under the following conditions:

-

Altitude: Below 1000m

-

Ambient temperature range: -5°C to 40°C

-

Humidity limits: Maximum monthly average relative humidity ≤90% at ≤25°C

-

Power stability: Voltage fluctuation within ±10% (at rated frequency); frequency fluctuation ≤±1% (at rated voltage)

Optional Accessories

Enhance functionality with our specialized add-ons:

-

Flux recovery system for efficient slag collection and reuse

-

Real-time monitoring system with weld parameter tracking

-

Adjustable shelving units for tool and material organization

-

Laser seam tracking for automated weld path correction

-

Cooling systems for extended operation in high-heat environments

Key Features & Benefits

✓ Heavy-duty construction for industrial welding durability

✓ Precision positioning for seam welding accuracy

✓ Modular design allowing welding automation integration

✓ Energy-efficient operation reducing welding production costs

✓ CE/ISO certified components ensuring welding safety compliance

Wuxi ABK Machinery Co.Ltd is a professional manufacturer of adjustable welding rotator in China. And we can also provide our clients around the world with many other products including special welding rotator, wind tower production line, H beam welding line, pipe welding equipment, CNC cutting machine, grinding machine, roll forming machine, plate bending machine, etc. We have obtained ISO and CE certification, and we also offer OEM service. Our products have been well received by customers from many countries, such as Spain, India, Germany, South Africa, Brazil, Chile, Argentina, Russia, Italy, France, Vietnam, and more. If you’re interested in our adjustable welding rotator, please don’t hesitate to contact us whenever you want.