Vertical Electrogas Welding Machine

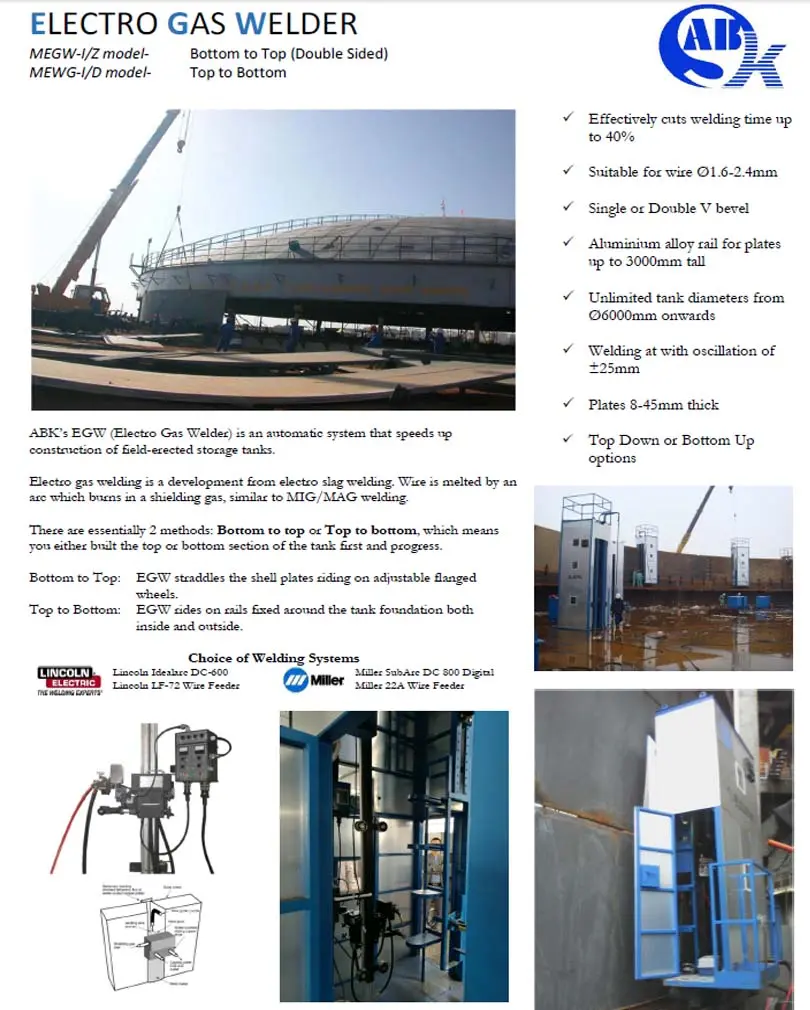

As a professional solution for vertical seam welding of large storage tanks, the WUXI ABK EGW(Electro Gas Welder) series of electroslag gas shielded automatic welding systems integrate the advantages of advanced electroslag welding and gas shielded welding technologies, and are specifically designed to provide efficient welding solutions for on-site assembled storage tank projects.

WUXI ABK Vertical Electrogas Welding Machine Product Introduction

Technical Advantages:

Our EGW Electro Gas Welding System represents a significant advancement in vertical seam welding technology, combining the benefits of traditional electroslag welding with modern gas-shielded processes. The system features our patented arc-slag composite heat source that increases welding efficiency by up to 40% compared to conventional methods. Designed for industrial-scale fabrication, this heavy-duty welding equipment accommodates material thicknesses from 8mm to 45mm with exceptional weld formation quality.

Key Technical Specifications:

-

Welding wire compatibility: ø1.6mm to ø2.4mm for various material requirements

-

Maximum applicable plate height: 3000mm with high-strength aluminum alloy track system

-

Diameter flexibility: Capable of welding storage tanks exceeding ø6000mm

-

Precision swing function: ±25mm amplitude for optimal thick plate welding quality

-

Dual welding direction options: Top-down and bottom-up configurations

Technical Principles:

The EGW system operates on an innovative hybrid principle that merges the arc stability of MAG welding with the deep penetration characteristics of electroslag welding. The shielding gas environment significantly improves weld metal mechanical properties, making it particularly effective for special materials including:

-

Low-temperature steels (e.g., LNG tank applications)

-

High-strength structural steels

-

Pressure vessel grade materials

Operation Modes:

-

Bottom to Top Mode:

Ideal for conventional storage tank construction where the base is installed first. The system moves upward with the welding process while maintaining gas protection over the molten pool. -

Top to Down Mode:

Specifically designed for specialized structures like floating roof tanks, operating on pre-installed tracks for maximum stability during the welding process.

Industry Applications:

WUXI ABK’s EGW system has been successfully implemented in:

-

Strategic petroleum reserve tank farms (vertical seam welding)

-

LNG cryogenic storage tank fabrication (9% nickel steel welding)

-

Chemical storage tank construction

-

Power generation equipment (desulfurization towers, etc.)

-

Large-diameter pressure vessel manufacturing

Quality Assurance and Support:

Every EGW system undergoes rigorous factory testing to ensure reliability. Our comprehensive support includes:

-

Customized welding solution design

-

Professional installation and commissioning

-

Operator training programs

-

24/7 technical support

-

Rapid spare parts supply

Wuxi ABK Machinery Co.Ltd is a professional manufacturer of adjustable welding rotator in China. And we can also provide our clients around the world with many other products including special welding rotator, wind tower production line, H beam welding line, pipe welding equipment, CNC cutting machine, grinding machine, roll forming machine, plate bending machine, etc. We have obtained ISO and CE certification, and we also offer OEM service. Our products have been well received by customers from many countries, such as Spain, India, Germany, South Africa, Brazil, Chile, Argentina, Russia, Italy, France, Vietnam, and more. If you’re interested in our adjustable welding rotator, please don’t hesitate to contact us whenever you want.