K11 K12 K13 Series Large Hole Self-centering Chuck

WUXI ABK K11/K12/K13 Series Large Hole Self-centering Chuck offers precision clamping for heavy-duty machining applications. Featuring high-accuracy centering (≤0.02mm) and large through-hole designs (up to φ300mm), these chucks provide superior gripping force for lathe and milling operations. Our hardened steel construction ensures durability, while the self-centering mechanism delivers consistent performance. Ideal for pipe flanges, bearings, and large-diameter workpieces.

K11 K12 K13 Series Large Hole Self-centering Chuck

Product Introduction: WUXI ABK K11/K12/K13 Series Large Hole Self-Centering Chucks

The WUXI ABK K11, K12, and K13 series self-centering chucks are engineered for precision and efficiency in industrial applications. These chucks feature an advanced plane thread structure, ensuring smooth and synchronized jaw movement through high-quality gears and coiled wires. This innovative design enables automatic centering of workpieces, significantly reducing setup time while maintaining exceptional accuracy.

Key Features of WUXI ABK Self-Centering Chucks

-

High Self-Centering Precision: The K11/K12/K13 series chucks deliver superior concentricity, ensuring minimal runout for high-precision machining.

-

Fast & Convenient Clamping: The self-centering mechanism allows quick workpiece alignment, enhancing productivity in repetitive operations.

-

High Rigidity & Clamping Force: Built for heavy-duty applications, these chucks provide strong gripping power and stability, even under high-speed machining conditions.

-

Durable Construction: Designed for longevity, the WUXI ABK chucks are made from high-grade materials to withstand rigorous industrial use.

Applications Across Industries

The WUXI ABK K11, K12, and K13 self-centering chucks are widely used in various machining and fabrication processes, including:

-

CNC Machining Centers – Ensures precise clamping for milling, drilling, and turning operations.

-

Lathes & Milling Machines – Ideal for high-accuracy part holding in both manual and CNC setups.

-

CNC Drilling Machines – Provides secure fixation for drilling large or complex components.

-

Welding & Cutting Equipment – Maintains stability during high-torque operations.

With their self-centering capability, high clamping force, and versatile compatibility, the WUXI ABK K11/K12/K13 series chucks are a reliable solution for industries demanding efficiency and precision. Whether in automotive, aerospace, or general manufacturing, these chucks enhance operational performance while reducing downtime.

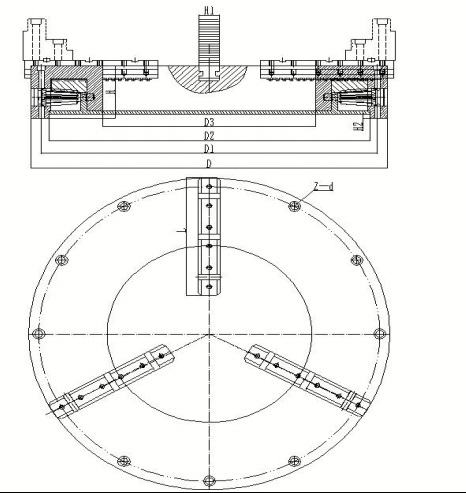

| Connection size parameters (selection reference, actual size is subject to the order drawing) | ||||||||||||||

| Specifications | D | D1 | D2(H7) | D3 | H | H1 | H2 | L | Z-d | |||||

| K11 400 | Ф400 | Ф368 | Ф340 | Ф170 | 100 | 36 | 6 | 125 | 6-M14 | |||||

| K11 500 | Ф500 | Ф465 | Ф440 | Ф240 | 115 | 45 | 6 | 185 | 6-M14 | |||||

| K11 630 | Ф630 | Ф590 | Ф560 | Ф320 | 125 | 50 | 12 | 250 | 6-M16 | |||||

| K11 800 | Ф800 | Ф760 | Ф730 | Ф480 | 130 | 50 | 12 | 320 | 6-M16 | |||||

| K11 1000 | Ф1000 | Ф950 | Ф902 | Ф640 | 150 | 60 | 15 | 350 | 9-M20 | |||||

| K11 1200 | Ф1200 | Ф1140 | Ф1080 | Ф850 | 150 | 60 | 15 | 350 | 9-M20 | |||||

| K11 1500 | Ф1500 | Ф1440 | Ф1380 | Ф1100 | 150 | 80 | 15 | 425 | 9-M20 | |||||

| Performance Parameter | ||||||||||||||

| Specifications | Maximum input torque | Maximum clamping force | Anti-claw clamping range | Positive claw clamping range | Remarks | |||||||||

| K11 400 500 | 500NM | 60KN | Ф50–450 | Ф50–450 | 1.Can undertake all kinds of sizes and forms of non-standard self-centering chuck customization.

2.The jaw length, four claws, six claws, eight claws and various styles of non-standard chucks can be customized. |

|||||||||

| K11 630 | 800NM | 72KN | Ф200–630 | Ф100-600 | ||||||||||

| K11 800 | 900NM | 80KN | Ф100–800 | Ф200-800 | ||||||||||

| K11 1000 | 1000NM | 90KN | Ф300–1000 | Ф200-1000 | ||||||||||

| K11 1200 | 1000NM | 100KN | Ф400–1200 | Ф300-1000 | ||||||||||

| K11 1500 | 1000NM | 120KN | Ф500–1500 | Ф400-1500 | ||||||||||

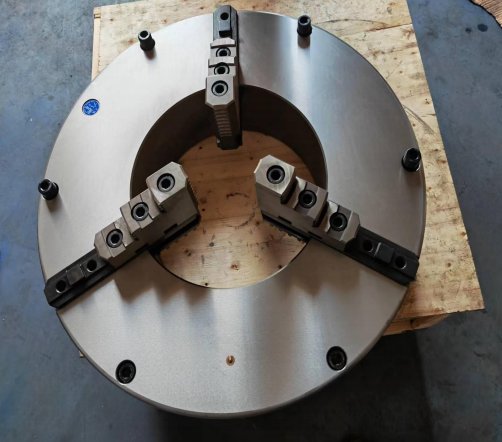

Application picture of K11 K12 K13 Series Large Hole Self-centering Chuck