Hydraulic Jacking System

As an innovator in the field of heavy engineering equipment, the turnover lifting system developed by WUXI ABK MACHINERY has become the industry benchmark for the installation of large storage tanks and the hoisting of heavy steel structures. Our system combines advanced hydraulic technology and intelligent control to provide safe and reliable solutions for the energy, electric power and chemical industries.

Core application field

Our heavy-duty tipping lifting system is designed for the following key application scenarios:

- Overturning operation of large storage tanks:It is especially suitable for the installation of large containers with a diameter of more than 10 meters, such as gas cabinets and desulfurization towers in power plants. The system can accurately control the overturning angle and speed to ensure construction safety.

- Hoisting of heavy steel structure:it can stably lift 500-ton large-scale structural members to meet the construction needs of bridges and workshops.

- Translation of super-large parts: Through precise synchronous control, positioning of heavy parts with millimeter accuracy can be realized, especially for occasions with extremely high requirements for installation accuracy such as nuclear power and petrochemical industry.

Design and composition of innovative system

- Efficient power system

The system adopts modular hydraulic pump station design and is equipped with high-precision flow/pressure control valve group. Electro-hydraulic drive technology accurately adjusts the oil circuit through solenoid valve to control:

- Lifting cylinder: provides main vertical displacement power.

- Clamping cylinder: ensure the load is fixed safely during operation.

This design not only improves the system reliability, but also greatly reduces energy consumption.

- Intelligent control system

Our intelligent control center includes:

- Central console: equipped with human-computer interaction interface (HMI) to realize all-round operation monitoring.

- Distributed control node: including pump start-stop control box and position/load sensor (real-time feedback).

- Hard-wired shielded cable network: ensuring stable signal transmission.

The system adopts closed-loop control logic, and the sensor data automatically triggers the sequential action of valves, thus realizing multi-point synchronous lifting, and the synchronous accuracy can reach ±2mm.

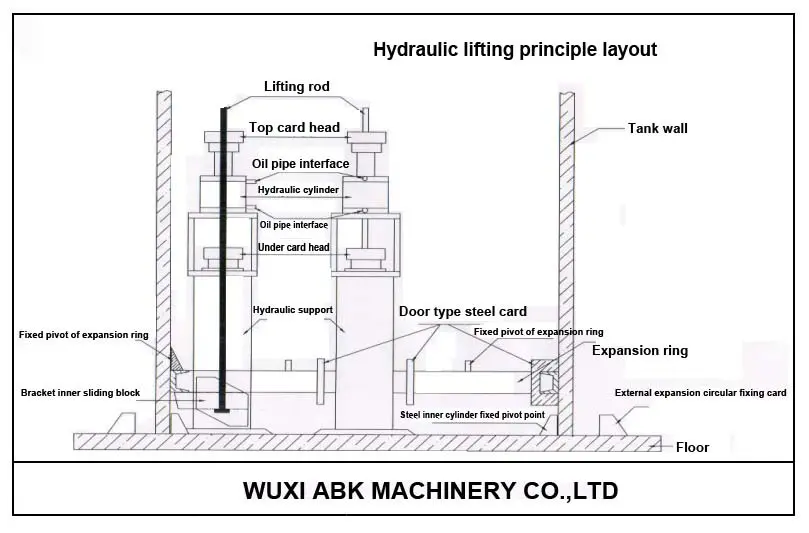

- Patented through-the-heart jack-up device

This innovative design has the following technical features:

- Hollow structure design: the central through hole can accommodate the load-bearing steel cable to realize more compact force transmission.

- Integrated clamping system: the upper and lower clamping units are mechanically coupled with the jack-up body, and the interlocking claw plates ensure effective force transmission.

- Load interface: Modular adapter kit can quickly connect various lifting lugs/flanges.

Technical advantage and value:

- Using military-grade hydraulic components, the system life is increased by 50%.

- Intelligent anti-swing algorithm to ensure the smooth movement of heavy objects

- Comply with ASME B30.20 and other international lifting equipment standards.

- Remote diagnosis function, greatly reducing downtime.

Technical Advantages

✅ Precision Load Management: Proportional valve control enables mm-level positioning accuracy.

✅ Fail-Safe Architecture: Redundant pressure relief circuits prevent overload scenarios.

✅ Heavy-Duty Performance: Standard configurations support 50-2000T capacities (customizable).

Typical Deployment Workflow

- Pre-Lift Engineering: Finite element analysis (FEA) verifies load distribution.

- Jack Array Configuration: Pattern optimization for center-of-gravity control.

- Lift Sequencing: Automated multi-stage elevation with tilt monitoring.

- Final Positioning: Hydraulic locking maintains position during bolting/welding.

Application:

Installation Methodology

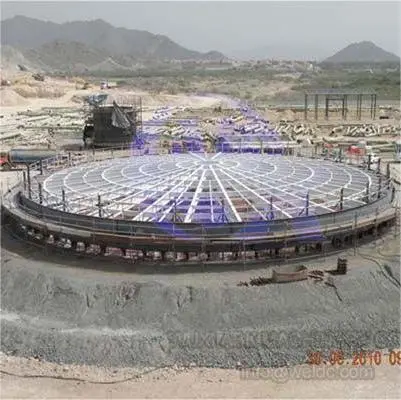

- Ground-Level Pre-Assembly

- All components are positioned at 0m elevationfor safe and efficient preparation.

- Processing includes:

- Coil alignment

- Surface rust treatment

- Welding (circumferential seams, reinforcement joints)

- Precision butt-joint fitting

- Incremental Flip-Up Installation

- The tower is constructed section-by-sectionusing hydraulic lifting systems:

- Each completed segment is welded at ground level.

- Hydraulic lifters elevate the assembled portion.

- Subsequent sections are added beneath the raised structure.

- This cycle repeats until reaching thefull design height.

✅ Eliminated High-Altitude Work

100% of welding/assembly occurs at ground level, removing fall risks.

✅ Controlled Construction Quality

Horizontal welding position improves joint integrity vs. overhead welding.

✅ Accelerated Project Timeline

Parallel processing: New sections are prepared while previous lifts are in progress.

✅ Hydraulic System Precision

Synchronized multi-point lifting prevents structural deformation.

Real-time load monitoring ensures stability during elevation.

Technical Implementation Workflow

| Phase | Activity | Safety Feature |

| 1. Pre-Lift | Segment fabrication & NDT inspection | Magnetic particle testing (MT) of welds |

| 2. Lift Execution | Hydraulic system engages lifting lugs | Redundant pressure relief valves |

| 3. Section Integration | Welding new segment to elevated structure | Temporary bracing & alignment lasers |

| 4. Height Iteration | Repeat until final elevation achieved | Strain gauge monitoring |

Advantages of Hydraulic Lifting Systems

1. Integrated Advanced Technology

A state-of-the-art fusion of hydraulic power, precision electronics, and automated control systems, delivering unmatched heavy-load handling capabilities in complex environments.

2. Key Performance Benefits

Compact & Lightweight Design

Minimal footprint with exceptional power-to-weight ratio.

Massive Load Capacity

Supports vertical lifting/placement of ultra-heavy components (2x safety factor vs. rated load).

Plug-and-Play Installation

Modular components enable rapid field deployment.

Intuitive Automated Operation

Single-console control with fail-safe programming.

3. Safety Engineering

Dual-Catch Fail-Secure Mechanism

Maintains load position during:

✓ Power outages

✓ Hydraulic line fractures

✓ Emergency stops

Guided Track Ascent

Precisely constrained movement eliminates lateral drift.

Synchronized Multi-Point Control

Real-time sensor feedback ensures ±2mm lifting uniformity.

4. Tank Lifting Specifics

Utilizes pressure-regulated grip/release cycles at the crown joint:

① Hydraulic clamps engage structural lugs

② Progressive elevation via synchronized jacks

③ Continuous load monitoring through PLC

Technical Specifications

| Parameter | Performance |

| Max. Tested Load | 200% nominal capacity |

| Positioning Accuracy | ±2mm (multi-jack systems) |

| Emergency Hold Time | ≥72 hours (mechanical lock) |

| Standard Power | 380V/50Hz or customizable |

Hydraulic lifting principle layout

Teshnical parameters of jack models

| Model/Description | ABK-JS25 | ABK-JS35 | ABK-JS50 | ABK-JS100 |

| Working capacity(metric tons) | 16 | 23 | 33 | 66 |

| Testing load(metric tons) | 25 | 35 | 50 | 100 |

| Standard arc distance between jacks(m) | 2 to 4 | |||

| Max plate height for which jacking equipment can be supplied(m) | 2.6 or more | |||

| Min plate height that can be used(m) | 0.10 | |||

| Plate thickness range(mm) | 5 and above | |||

| Unitary climb(cm/stroke) | 10 | |||

| Time per stroke(second) | 50 to 80 | |||

| Piston retracting system | Spring | |||

Wuxi ABK Machinery Co.Ltd is a professional manufacturer of adjustable welding rotator in China. And we can also provide our clients around the world with many other products including special welding rotator, wind tower production line, H beam welding line, pipe welding equipment, CNC cutting machine, grinding machine, roll forming machine, plate bending machine, etc. We have obtained ISO and CE certification, and we also offer OEM service. Our products have been well received by customers from many countries, such as Spain, India, Germany, South Africa, Brazil, Chile, Argentina, Russia, Italy, France, Vietnam, and more. If you’re interested in our adjustable welding rotator, please don’t hesitate to contact us whenever you want.