CNC Laser Cutting Machine

WUXI ABK CNC Fiber Laser Cutting Machine delivers precision metal cutting with advanced 500W/1000W fiber laser technology. Featuring HIWIN guides, Panasonic servos, and Germany Befo control system, it ensures high-speed, energy-efficient processing of steel, aluminum, and copper. Integrated dust removal maintains clean operation. Ideal for automotive, aerospace, and sheet metal fabrication industries.

Principle of Operation

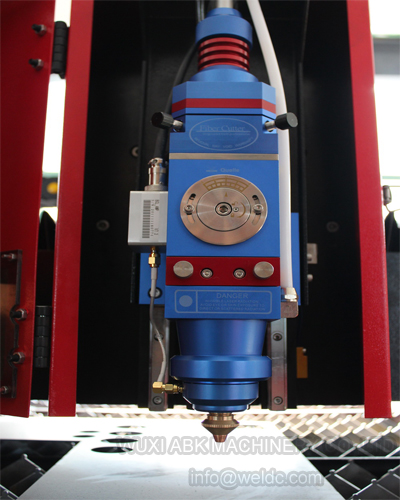

The CNC fiber laser cutting machine utilizes advanced fiber laser technology to deliver high-precision, high-efficiency metal cutting. The laser generator produces a high-energy laser beam, which is transmitted through a fiber optic cable to the cutting head. The precision focusing lens group concentrates the laser beam into a micron-level focal point (approximately 0.1mm in diameter), generating an instantaneous temperature exceeding 10,000℃. This extreme heat causes the material to vaporize instantly, while a high-pressure auxiliary gas (O₂/N₂) blows away molten residue, ensuring clean, smooth cuts. An integrated dust removal system efficiently eliminates cutting debris in real time, maintaining a clean working environment and prolonging machine life.

Core Configuration

1. Laser System

-

Fiber laser source: Equipped with a Wuhan Ruike 500W pulsed fiber laser (optional 1000W high-power laser for thicker materials).

-

Laser wavelength: 1070nm, ensuring optimal absorption by metal materials.

-

Photoelectric conversion efficiency: Over 30%, reducing energy consumption and operational costs.

-

Beam quality monitoring: Includes a high-precision beam quality analyzer (imported from the UK) for consistent cutting performance.

2. Transmission System

-

Linear guide rails: Taiwan HIWIN high-rigidity silver rails (20mm), ensuring smooth and stable motion.

-

Servo motors: Original Panasonic servo motors (X-axis: 1000W, Y-axis: 3000W) for high-speed, high-torque movement.

-

Ball screws: C3-grade precision ball screws (32mm diameter), minimizing backlash and enhancing positioning accuracy.

3. Control System

-

Motion control: Germany Befo multi-axis motion control card, ensuring ultra-precise cutting path execution.

-

Software compatibility: Supports DXF/DWG/AI file formats for seamless CAD/CAM integration.

-

Cutting parameter database: Real-time adjustment of laser power, cutting speed, and gas pressure for optimized performance across different materials.

Key Advantages

-

High-speed cutting: Optimized fiber laser technology enables rapid processing of stainless steel, carbon steel, aluminum, and copper.

-

Energy-efficient operation: 30%+ photoelectric conversion efficiency reduces power consumption.

-

Low maintenance: Fiber laser cutting systems require minimal upkeep compared to CO₂ lasers.

-

Automated dust removal: Integrated extraction system ensures a clean workspace and extends machine longevity.

This CNC laser cutting machine is ideal for industries requiring precision metal fabrication, including automotive, aerospace, electronics, and sheet metal processing. With its high-power fiber laser source, robust transmission system, and intelligent control software, it delivers superior cutting accuracy, efficiency, and reliability.

Technical parameter

| Project | Specifications | Superiority |

| Working width | 1500×3000mm | Support customization 2000×4000mm |

| Positioning accuracy | ±0.02mm | Laser interferometer calibration |

| Cutting accuracy | ≤±0.08mm | Superior to industry standards |

| Repeatability | ±0.01mm | Satisfy precision machining |

| Maximum acceleration | 1.5G | Shorten the idle time |

Main Components

| Component | Brief Introduction | Manufacturer Info |

| Laser Device | China Wuhan Optical Valley Raycus 500W fiber laser | Wuhan Raycus |

| Optical system | Wuhan Raycus laser power | England |

| Laser Power | 600W pulse laser system | Wuhan Raycus |

| Cutting Head | Professional high precision head | ABK Technology |

| Cooling System | Overtemperature protection, temperature stability±0.5℃, environmental protection two-cycle water-cooling machine, titanium alloy evaporation tube control, 2P all in one cooling tank | ABK Technology |

| Mechanical Drive System | High precision ball screw; original Panasonic Servo Motor; Taiwan HIWIN Guide Rail | HIWIN, Taiwan |

| Tracking & Sensing System | High precision self sensing; accuracy ±0.1mm | ABK Technology |

| Working Area | 1500×3000mm | Made in China |

| Computing System | IPC | Made in China |

| X Axis Servo Unit | 1000W single driven | Panasonic |

| Y Axis Servo Unit | 3000W single driven | Panasonic |

| Limit Switch | NPN | Omron |

| Cutting Software | V2.0 | ABK Technology |

| I/O Card | 32 points | Googol, Shenzhen |

| Working Platform | Gantry type | ABK Technology |

Main Indexes of QY-LCF500 Laser Cutting Machine

| Laser Wavelength | 1070nm |

| Maximum Laser Output Average Power | 500W |

| Laser Repeated Frequency | CW |

| Power Instability | =<2% |

| Minimum Line Cutting | 0.2mm (for material below 0.4mm) |

| Maximum Cutting Speed | =<15m/min (depends on different material) |

| Maximum Cutting Thickness | =<5mm (carbon steel) =<4mm (stainless steel) |

| Continuous Operating Time | >=20 hours |

| Maximum Cutting Breath | 3000mm*1500mm |

| Working Platform Accuracy | ±0.08mm |

| Repeat Location Accuracy | ±0.02mm |

| Power Supply | Three-phase five line exchange 380V±5%, 50Hz±1% |

| Software | Phase selecting provided |

| Weight of the Machine (Estimated) | 4200kg |

Equipment Cutting Indexes(This is only for your reference. Speed may be different as for different figure. It should be based on the practical test results.)

| Material | Thickness (mm) | Speed (mm/s) | Auxiliary Gas | Remark |

| Stainless Steel | 0.3 | 240 | O2 | Limiting Velocity |

| Stainless Steel | 0.5 | 200 | O2 | Limiting Velocity |

| Stainless Steel | 1 | 180 | O2 | Limiting Velocity |

| Stainless Steel | 2 | 110 | O2 | Limiting Velocity |

| Stainless Steel | 3 | 45 | O2 | Limiting Velocity |

| Stainless Steel | 4 | 24 | O2 | Limiting Velocity |

| Stainless Steel | 5 | 20 | O2 | Limiting Velocity |

| Stainless Steel | 0.3 | 150 | N2 | Limiting Velocity |

| Stainless Steel | 0.5 | 130 | N2 | Limiting Velocity |

| Stainless Steel | 1 | 100 | N2 | Limiting Velocity |

| Stainless Steel | 1.2 | 90 | N2 | Limiting Velocity |

| Stainless Steel | 1.5 | 60 | N2 | Limiting Velocity |

| Stainless Steel | 2 | 40 | N2 | Limiting Velocity |

| Stainless Steel | 2.5 | 12 | N2 | Limiting Velocity |

| Carbon Steel | 1 | 170 | O2 | Limiting Velocity |

| Carbon Steel | 2 | 80 | O2 | Limiting Velocity |

| Carbon Steel | 3 | 40 | O2 | Limiting Velocity |

| Carbon Steel | 4 | 20 | O2 | Limiting Velocity |

| Carbon Steel | 5 | 15 | O2 | Limiting Velocity |

| Carbon Steel | 6 | 10 | O2 | Limiting Velocity |

| Aluminium Sheet | 1 | 80 | O2 | Limiting Velocity |

Accessories and Specifications

| Item | Quantity | Remark |

| Specifications | 1 piece | |

| Protective Lens | 5 pieces | For free |

| Spray Nozzle | 2 pieces | For free |

| Inner Hexagon Wrench | 1 set | For free |

| Professional Polishing Paper | 1 piece | For free |

|

Terms of the transaction 1. Price description l The product quotation includes 17% VAT (special VAT invoice can be issued). l EXW (optional CIP/DDP terms) 2. Delivery cycle l Standard model: delivered within 30 working days after signing the contract. l Customized model: 45-60 working days (subject to contract confirmation) 3. Payment types/methods l 30% down payment (contract signing) l 50% of the progress payment (before the equipment leaves the factory) l 20% of the balance (after acceptance) Quality assurance (control) system ◇ Whole process quality control Raw materials: Baowu/Shougang high-quality steel is adopted. Production process: implementing ISO9001 quality management system. Ex-factory inspection: 72 hours continuous operation test ◇ Warranty clause The warranty of the whole machine is 12 months (24 months for laser) List of wearing parts: protective lenses/nozzles/filter elements, etc. Full-cycle service system 1. Pre-sales support ✓ Free technical consultation Provide process plan design Material trial cutting service (limited to 3 times) Suggestions on workshop layout planning ✓ value added service Professional selection software support Return on investment analysis report Comparative evaluation of similar equipment Installation training Standard service package: ▶ Installation of equipment in place (compliance site shall be provided by customers) ▶ Mechanical/electrical system debugging ▶ 5-day systematic training (2-3 people) l Safe operation of laser (OSHA standard) l Software programming practice l Daily maintenance specification l Common fault handling Optional upgrade service: ▶ Integrated debugging of production line (additional quotation required) ▶ Multi-shift training (+3 days) Acceptance process ① Factory Pre-acceptance (FAT) ② On-site installation and debugging (SAT) ③ 72-hour continuous production test ④ Final acceptance document signing After-sales service Quick response: Ø 400 service hotline (7×24 hours) Ø Technical response within 2 hours Ø 24-hour engineer presence (domestic) Service content: Ø Annual preventive maintenance (4 times) Ø Remote diagnosis support Ø Rapid supply of spare parts (standing 100+ categories) |