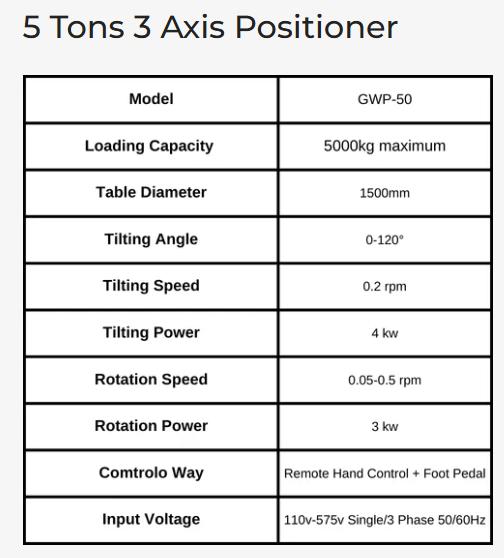

5 Tons 3 Axis Positioner

WUXI ABK 5-Ton 3-Axis Welding Positioner delivers precision rotation and tilting for robotic welding applications. Featuring ±0.5° positioning accuracy, this industrial-grade positioner handles automotive components, structural steel, and pressure vessels with 5000kg capacity. Its servo-driven 3-axis movement ensures perfect weld angles, while CNC-ready controls enable seamless automation integration. CE/ISO certified for quality assurance.

5 Tons 3 Axis Positioner Parameter Table

Precision Multi-Axis Control

The WUXI ABK 5-ton 3-axis welding positioner delivers exceptional maneuverability with synchronized turning (180°), rotating (360° continuous), and tilting (0-90°) movements. Engineered for robotic welding integration, it achieves ±0.05mm positioning accuracy and 0.02mm repeatability, making it ideal for precision fabrication of pressure vessels, structural components, and automotive parts.

Heavy-Duty Construction

Built with an integral casting base, this industrial positioner handles dynamic loads up to 5 tons while maintaining stability. Premium components include:

-

Japan THK linear guides for smooth motion control

-

Germany SEW reducers ensuring torque precision

-

Reinforced steel frame for vibration resistance

Smart Safety & Automation

The welding positioner features:

✓ Overload protection with auto power-off

✓ <0.1s emergency braking

✓ PLC/touchscreen dual control for flexible operation

✓ ABB/KUKA robot compatibility for automated welding cells

Applications

Perfect for aerospace fixtures, shipbuilding jigs, and heavy machinery fabrication, this 3-axis positioner adapts to MIG, TIG, and submerged arc welding.

1.Slewing bearing

Slewing bearing is the force basic element of machine, which requires relative rotation between all two parts and bears axial force, radial force and overturning moment at the same time.Its basic function is to use bolts to fix it on the upper and lower supports of mechanical equipment to transmit force and drive so as to realize the relative rotation between the two parts of mechanical equipment.Rotary support generally has installation holes, internal or external gears, lubrication holes and sealing devices. It has the characteristics of compact structure, light weight, good structural steel, smooth operation, high accuracy, safety and reliability.

Slewing bearing is a basic part of mechanical equipment and widely used in various industries of national economy. It is widely used in construction machinery, port machinery, metallurgical machinery, mining machinery, petroleum machinery, chemical machinery, medical equipment, ship machinery, light industrial machinery, environmental protection machinery, entertainment equipment, transportation machinery equipment.Swing supports are increasingly used in energy-saving and environmental protection projects, such as wind turbines that require a variety of precision pole swing support kits.

2.Gear

Gear is a wheel like mechanical part which transmits the torque by the engagement of teeth. Through the transmission with other toothed mechanical parts (such as another gear, Dao rack and worm), the gear can change the speed and torque, change the direction of motion and change the form of motion.

3.Reducer

The reducer is a kind of power transmission mechanism, which uses the speed converter of gear to reduce the rotation number of motor to the required rotation number and obtain a structure with large torque.

Function of reducer:Reduce the speed and increase the output torque at the same time. The torque output ratio is multiplied by the motor output deceleration ratio, but it shall not exceed the rated torque of the reducer.At the same time, the inertia of the lo.ad is reduced to the square of the deceleration ratio.

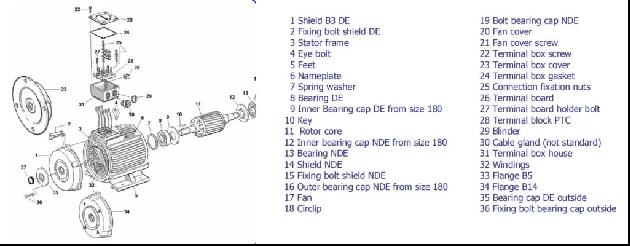

4.Motor

WUXI ABK 5-Ton 3-Axis Welding Positioner Maintenance & Service Guide

Proper maintenance of our 5-ton 3-axis welding positioner ensures optimal performance for precision welding applications in automotive fabrication, pressure vessel manufacturing, and structural steel assembly. This industrial-grade positioner with ±0.5° tilt-rotate accuracy requires systematic care to maintain its CNC synchronization capability and long-term reliability.

Core Maintenance Procedures

-

Daily Care

-

Remove welding spatter and debris from the 3-axis turntable

-

Verify lubrication levels in the worm gear reducer

-

Inspect electrical connections and servo motor performance

-

-

Scheduled Maintenance

-

Monthly: Tighten all high-strength fasteners (85-110Nm torque)

-

Quarterly: Test emergency stop functions and limit switches

-

Annually: Replace wear components (bearings, seals) and recalibrate axis alignment

-

Critical Maintenance Benefits

✓ Extends equipment service life by 30%+ through proper gearbox lubrication

✓ Prevents unscheduled downtime in robotic welding cells

✓ Maintains ±0.2mm repeatability for high-precision applications

Fault Prevention Protocol

-

Immediate shutdown required for:

▶ Abnormal vibration in rotary axis

▶ Irregular tilting movement

▶ Electrical faults in PLC control system

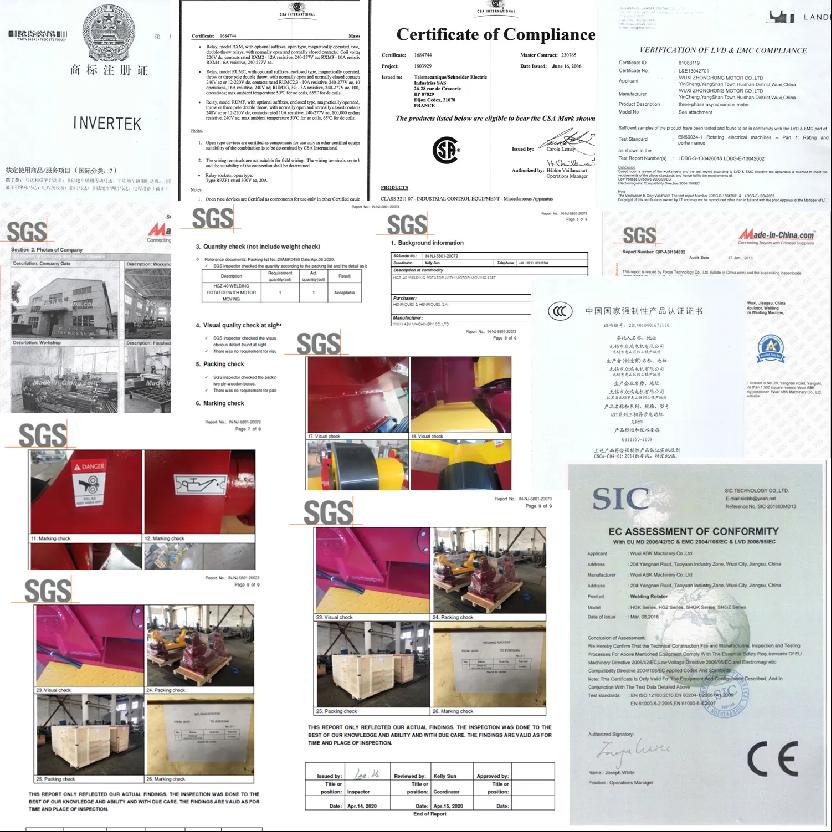

Certification & Support

This CE/ISO certified positioner comes with:

-

12-month warranty on drive components

-

Free technical training for operators

-

Preventive maintenance kits available (Part No. PMK-5T3A)

Wuxi ABK Machinery Co.Ltd is a professional manufacturer of welding rotator in China. And our welding rotator mainly includes standard welding rotator, adjustable welding rotator, and special welding rotator. We can also provide our clients around the world with many other products including welding turntable, pile welding machine, wind tower production line, H beam welding line, pipe welding equipment, CNC cutting machine, grinding machine, roll forming machine, plate bending machine, etc. We have obtained ISO and CE certification, and we also offer OEM service.