300Tons Adjustable Welding Rotator

WUXI ABK’s 300Tons Heavy-Duty Welding Rotator delivers precision rotation for large-diameter pipeline welding, pressure vessel fabrication, and structural steel applications. This industrial-grade positioner features robust 3-axis hydraulic control, anti-slip roller technology, and accommodates workpieces up to 5m diameter. With dual-motor drive and PLC automation compatibility, it ensures ±0.5° accuracy for shipbuilding, wind tower, and offshore platform projects. CE/ISO certified with 24-month warranty.

Description of Adjustable Welding Rotator

Parameter list of conventional HGK-300 welding rotator

| Model | HGK-300 | |

| Load capacity(Ton) | 300 | |

| Wheel diameter(mm) | 800 | |

| Wheel width(mm) | 300(metal) | |

| Vessel diameter | MIN(mm) | 1000 |

| MAX(mm) | 6000 | |

| Wheel velocity(m/h) | 6-60 | |

| Motor Power(kw) | 2*5.5 | |

Parameter list of conventional HGK series welding rotator

WUXI ABK’s 300Tons Adjustable Welding Rotator is a heavy-duty industrial solution designed for large-scale fabrication of pressure vessels, wind towers, and ship components. Featuring a robust 3-axis hydraulic system with ±0.5° rotation accuracy, this rotator accommodates workpieces up to 5m diameter. Its dual-motor drive and anti-slip roller technology ensure stable performance for pipeline girth welding and structural steel applications. The PLC-ready system offers 0.5-5 RPM speed control with <0.5mm creep prevention, making it ideal for offshore platform construction and energy equipment manufacturing. CE & ISO certified with 24-month warranty.

Maintenance of Welding Rotator

1. This welding rotator needs cleaning before putting into use. And to avoid aging, the rubber rollers should stay away from oils and high temperature. If possible, there should be a specific person to operate and maintain this device.

2. Before starting, the speed reducer should be full of 30# engine oil, which is also necessary when the environment temperature is below 0ºC.

3. The oil inside the speed reducer should be completely replaced after the use of first month, and later, the engine oil can be changed every six months.

4. The roller bed can not be used as the welding ground so that bearings can be prevented from damaging.

Features of Welding Rotator

- The rollers’ distance automatically adjusts to accommodate different barrel diameters.

Speed is adjustable via a frequency control system, enhancing operational reliability.

3.Easy operation is ensured with a manual control box.

4.Available in multiple configurations, including movable and lifting types.

5.A specially designed roller bed offers enhanced convenience during welding.

6.Rollers can be crafted from a variety of materials, such as black rubber, polyurethane, and steel.

Product details

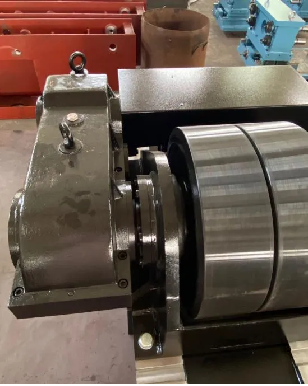

| · Trusted design | · Reliable Quality |

| · Renowned parts | · Inverter control |

| · Direct drive system | · Motorised travel option |

| · Build to order custom design | · OEM |

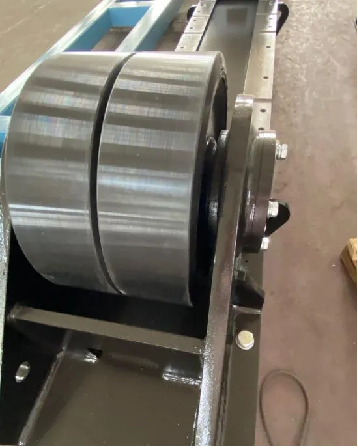

Wheel introduction

Polyurethane wheels offer exceptional abrasion resistance, versatile processing, wide applicability, and superior resistance to oil, ozone, aging, radiation, and low temperatures. They also provide strong adhesion, excellent sound transmission, biocompatibility, and blood compatibility.

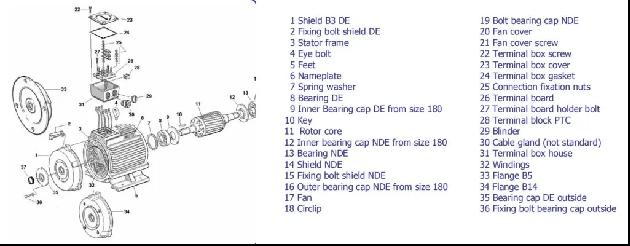

Motor introduction

WUXI ABK 300Tons Welding Rotator Maintenance & Service Guide

For optimal performance of your heavy-duty welding rotator, follow these maintenance procedures to ensure longevity and precision in pressure vessel fabrication, wind tower production, and shipbuilding applications:

-

Pre-Operation Care

-

Clean the rotator thoroughly before use.

-

Protect rubber rollers from oil exposure and high temperatures to prevent premature aging.

-

Assign trained personnel for operation and maintenance.

-

-

Lubrication Requirements

-

Fill the speed reducer with 30# engine oil prior to startup, particularly in sub-zero conditions (<0°C).

-

Replace oil after the first month of operation, then every six months thereafter.

-

-

Critical Safety Measures

-

Never use the roller bed as a welding ground—this can damage bearings and affect rotation accuracy.

-

Why Choose WUXI ABK?

As a leading rotator manufacturer with 20+ years of expertise, we deliver:

✔ 5-400 ton capacity rotators for industrial welding automation

✔ CE & ISO certified designs compliant with global safety standards

✔ 1-year warranty with free replacement of wear parts

✔ Dedicated technical support for large-scale projects (e.g., wind turbine welding, offshore construction)

Trust our high-precision rotators to enhance productivity in pipeline girth welding, structural steel fabrication, and energy equipment manufacturing.

Wuxi ABK Machinery Co.Ltd is a professional manufacturer of welding rotator in China. And our welding rotator mainly includes standard welding rotator, adjustable welding rotator, and special welding rotator. We can also provide our clients around the world with many other products including welding turntable, pile welding machine, wind tower production line, H beam welding line, pipe welding equipment, CNC cutting machine, grinding machine, roll forming machine, plate bending machine, etc. We have obtained ISO and CE certification, and we also offer OEM service.