3 tons Fixed Height Positioner

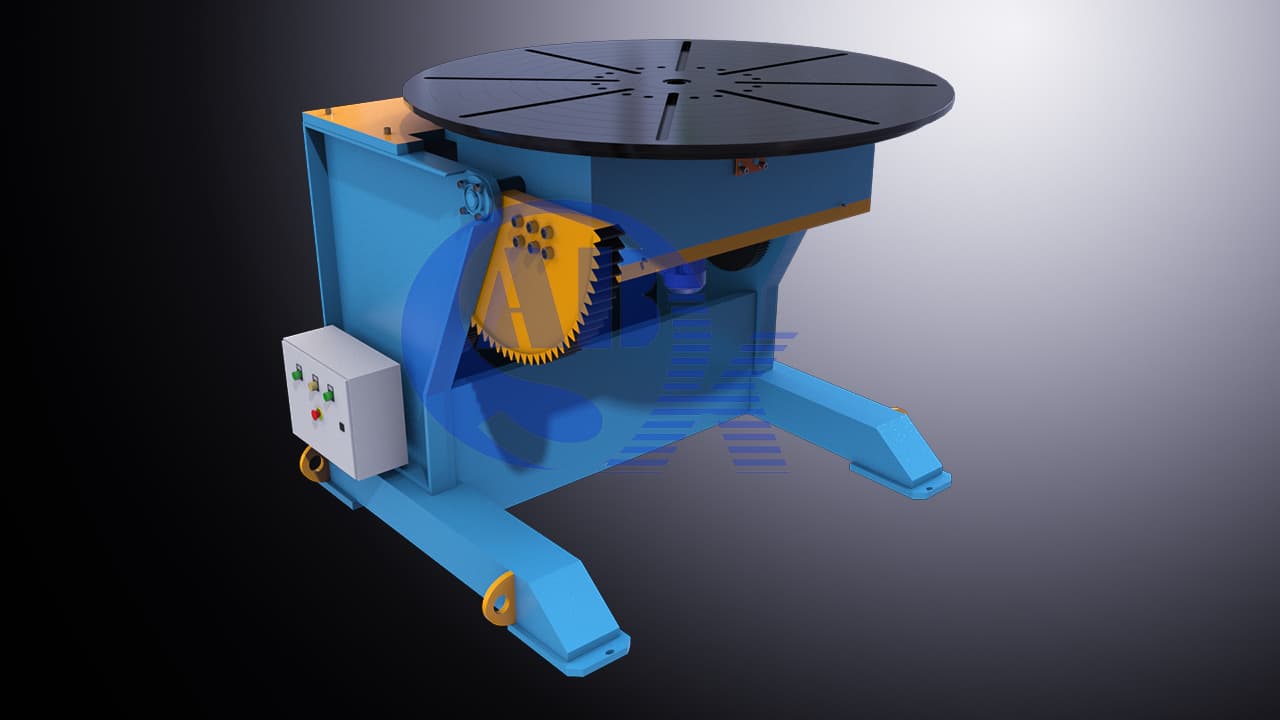

The WUXI ABK 3-Ton Fixed Height Positioner provides reliable workpiece rotation for welding applications, featuring a 3,000kg capacity and 0-135° tilt range. Its variable speed drive (0.1-2 RPM) ensures precise control, while the heavy-duty steel construction offers durability for industrial environments. The integrated conductive system prevents cable twisting, making it ideal for fabricating medium-sized components in manufacturing and repair operations. CE/ISO certified.

3 tons Fixed Height Positioner

| Model | HBJ-30 | |

| Load Capacity | (KG) | 3000 |

| Rotating Speed | (RPM) | 0.05-0.5 |

| Turnover Speed | (RPM) | 0.23 |

| Turnover Angle | (°) | 0-90 |

| Worktable Size | (MM) | 1400 |

| Turning power | (KW) | 1.5 |

| Overturning power | (KW) | 2.2 |

| Maximum Eccentric Distance | (MM) | 200 |

| Maximum Center-of-gravity Distance | (MM) | 400 |

| Power Supply | 50Hz 3ɸ (V) | 380 (Determined according to customer needs) |

| Speed Regulating Type | AC Frequency Stepless Speed Regulation | |

| Note: All specifications are of the standard equipment, that may be changed to suit the customers’ requirement. | ||

Precision Engineering for Industrial Applications

The WUXI ABK 3-Ton Fixed Height Welding Positioner delivers exceptional performance in heavy equipment manufacturing, energy sector fabrication, and transportation industry applications. Designed for demanding production environments, this welding positioner features a heavy-duty worktable with 6 T-slot clamping system, providing rigid fixation for workpieces up to 2,000kg. The 360° continuous rotation capability, powered by a precision servo drive with adjustable speed from 0.1 to 1.2 RPM, ensures optimal positioning for complex welds. Integrated conducting slip rings eliminate cable twisting during operation, maintaining clean workspaces and reducing maintenance downtime.

Advanced Drive System Technology

At the core of this industrial welding positioner lies our advanced drive system:

-

Turning Mechanism: AC motor coupled with planetary gear reducer delivers ±0.5° positioning accuracy

-

Tilting System: Cycloidal-worm dual-stage reducer provides smooth 0-135° tilt range

-

Control Interface: Siemens PLC with HMI touchscreen offers 100+ preset welding programs

Customizable Solutions for Specialized Needs

WUXI ABK offers extensive customization options to meet specific welding positioner requirements:

-

Load capacities from 500kg to 5,000kg

-

Worktable diameters ranging 800mm-3,000mm

-

Special configurations including:

✓ ATEX Zone 1 explosion-proof certification

✓ CNC synchronization for robotic welding cells

✓ Water-cooled tables for high-heat applications

Industry-Proven Performance

This fixed height welding positioner excels in critical applications:

-

Heavy Equipment: Precise positioning of excavator booms and crane segments

-

Energy Sector: Flawless welding of wind turbine flanges and pressure vessels

-

Transportation: Accurate fabrication of rail bogies and shipbuilding components

Key Technological Features

The positioner incorporates multiple innovations:

-

Variable Speed Control: Frequency conversion drive enables smooth 0.1-2 RPM adjustment

-

Stepless Regulation: Eliminates gear shifting for uninterrupted operation

-

Precision Tilt: Dual semicircular gears with worm reducer ensure stable movement

-

Current Conduction: Rotary interface prevents cable entanglement

-

Robust Construction: Stress-relieved Q235-A steel base with precision machining

Technical Specifications

-

-

Max Load Capacity: 3,000kg (standard), upgradable to 5,000kg

-

Rotation Speed: 0.1-2 RPM continuously adjustable

-

Tilt Range: 0-135° with ±0.5° repeatability

-

Control System: Siemens S7-1200 PLC with 10″ HMI

-

Power Requirements: 380V/50Hz (other voltages available)

-

Technical Parameters of HBJ Series Welding Positioner:

| Model | HBJ-01 | HBJ-03 | HBJ-06 | HJB-12 | HBJ-30 | HBJ-50 | HBJ-100 | |

| Rated load capacity (kg) | 100 | 300 | 600 | 1200 | 3000 | 5000 | 10000 | |

| Turning speed(rpm) | 0.4-4 | 0.1-1 | 0.09-0.9 | 0.05-0.5 | 0.05-0.5 | 0.05-0.5 | 0.05-0.2 | |

| Overturn speed(rpm) | handle | 1.1 | 0.67 | 0.23 | 0.14 | 0.14 | ||

| Diameter of working table(mm) | ¢400 | ¢600 | ¢1000 | ¢1200 | ¢1400 | ¢1500 | ¢2000 | |

| Turning angle (°) | 0-120 | 0-90 | 0-90 | 0-120 | ||||

| Motor power (KW) | Turning | 0.06 | 0.37 | 0.75 | 1.1 | 1.5 | 3 | 5.5 |

| Overturning | 0.75 | 2.2 | 1.5 | 3 | 5.5 | |||

| Speed regulation Type | Stepless frequency conversion | |||||||

| Max. gravity distance(mm) | 100 | 100 | 100 | 150 | 200 | 300 | 400 | |

| Max. eccentricity (mm) | 150 | 150 | 150 | 200 | 200 | 300 | 400 | |

| Max. rotating diameter when 90° overturned (mm) | ¢600 | ¢800 | ¢1500 | ¢2050 | ¢2100 | ¢2500 | ¢3240 | |

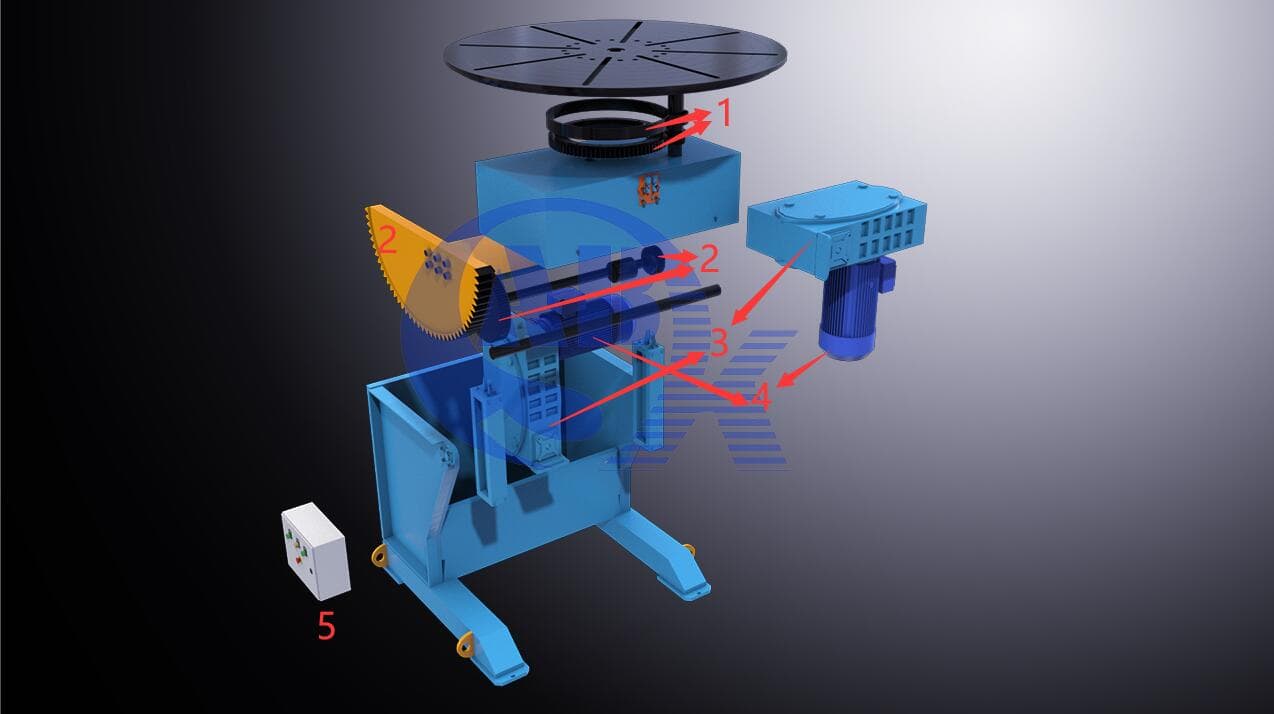

1. Slewing bearing

The slewing bearing is a critical load-bearing component that enables relative rotation between machine parts while simultaneously handling axial, radial, and overturning moment forces. Its compact and lightweight design, made from high-strength alloy steel, ensures smooth operation with high precision (±0.05° rotation accuracy) and long service life. Key configurations include mounting bolt holes, optional internal/external gears, lubrication ports, and sealing systems for enhanced reliability. With a diameter range of 300–5000mm and load capacity up to 50,000kN, it is widely used in construction machinery, wind turbines, cranes, and military equipment. Custom designs are available for specialized applications.

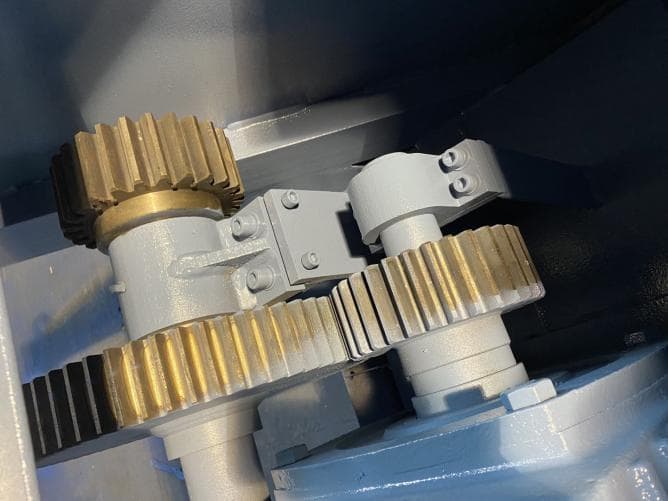

- Gear

1). Reverse gear

Generally, the turning angle of the turning gear is 0 °to 90 °. The function of displacement is achieved by turning the table.

2). Reverse gear

Gears are toothed mechanical components that transmit torque through meshing engagement with other gear elements like racks, worms or additional gears, enabling precise control over power transmission by modifying speed/torque ratios, redirecting motion paths, and converting motion types (e.g., rotary to linear). Their interlocking teeth design provides reliable force transfer while allowing for customizable mechanical advantage in various industrial applications.

3.Reducer

Gear reducers are mechanical power transmission devices that utilize precision gear systems to reduce input speed while proportionally increasing output torque, with the output torque being the product of motor torque and gear ratio (without exceeding the reducer’s rated capacity). These systems simultaneously decrease load inertia by the square of the reduction ratio, enabling optimized power conversion for various industrial applications through efficient gear engagement.

Welding Turntable Maintenance Guidelines

Core maintenance content

Daily maintenance-cleaning welding slag, checking lubrication and electrical safety.

Regular maintenance-tighten bolts, check transmission mechanism and test safety function.

Deep maintenance-annual replacement of worn parts, re-lubrication and system calibration

Fault early warning-Stop immediately when abnormal noise/uneven rotation occurs.

Maintain value

- Extend the service life of equipment by more than 30%

- Reduce sudden downtime

- Ensure the stability of welding accuracy.

Product certification

Step into the future of welding technology with our cutting-edge solutions.

From automated processes to intuitive controls, our products are at the forefront of innovation, providing you with the tools you need to stay ahead in today’s competitive market!

Wuxi ABK Machinery Co.Ltd is a professional manufacturer of welding rotator in China. And our welding rotator mainly includes standard welding rotator, adjustable welding rotator, and special welding rotator. We can also provide our clients around the world with many other products including welding turntable, pile welding machine, wind tower production line, H beam welding line, pipe welding equipment, CNC cutting machine, grinding machine, roll forming machine, plate bending machine, etc. We have obtained ISO and CE certification, and we also offer OEM service.