3 Tons 3 Axis Positioner

WUXI ABK 3-Ton 3-Axis Welding Positioner delivers precision workpiece positioning for robotic welding and fabrication. Featuring ±0.5° tilt-rotate accuracy, servo-driven axes, and CNC synchronization, this compact positioner excels in automotive, aerospace, and precision parts manufacturing. With 360° continuous rotation and 135° tilting range, it ensures optimal weld access. CE/ISO certified with IP54 protection for industrial environments.

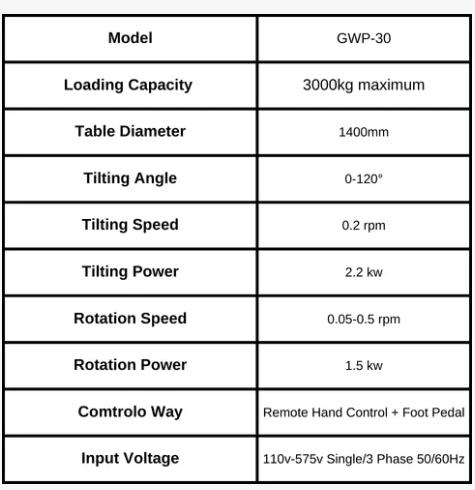

3 Tons 3 Axis Positioner Parameter Table

The WUXI ABK 3-Ton 3-Axis Positioner is a high-precision industrial welding equipment designed for complex fabrication tasks, delivering three-axis synchronous movement with turning (180°), rotating (360° continuous), and tilting (0-90°) capabilities. Its ±0.05mm positioning accuracy and 0.02mm repeatability ensure superior weld quality for robotic welding systems and automated production lines.

Structural Advantages

Built with a heavy-duty cast base, this welding positioner supports dynamic loads up to 5 tons, reinforced with Japan THK linear guides and Germany SEW reducers for unmatched stability. The intelligent safety system features overload auto-shutdown and emergency braking (<0.1s response), making it ideal for high-risk welding environments.

Key Features

-

Multi-brand robot compatibility (ABB, KUKA, FANUC, etc.)

-

Dual control modes (PLC + touchscreen) for flexible operation

-

CE & ISO certified with IP54 protection for harsh conditions

-

Adaptive to arc welding, laser welding, and plasma applications

Applications

Perfect for automotive chassis welding, aerospace components, and precision machinery fabrication, this 3-axis positioner enhances productivity in high-mix, low-volume production.

1.Slewing bearing

Slewing bearing is the force basic element of machine, which requires relative rotation between all two parts and bears axial force, radial force and overturning moment at the same time.Its basic function is to use bolts to fix it on the upper and lower supports of mechanical equipment to transmit force and drive so as to realize the relative rotation between the two parts of mechanical equipment.Rotary support generally has installation holes, internal or external gears, lubrication holes and sealing devices. It has the characteristics of compact structure, light weight, good structural steel, smooth operation, high accuracy, safety and reliability.

Slewing bearing is a basic part of mechanical equipment and widely used in various industries of national economy. It is widely used in construction machinery, port machinery, metallurgical machinery, mining machinery, petroleum machinery, chemical machinery, medical equipment, ship machinery, light industrial machinery, environmental protection machinery, entertainment equipment, transportation machinery equipment.Swing supports are increasingly used in energy-saving and environmental protection projects, such as wind turbines that require a variety of precision pole swing support kits.

2.Gear

Gear is a wheel like mechanical part which transmits the torque by the engagement of teeth. Through the transmission with other toothed mechanical parts (such as another gear, Dao rack and worm), the gear can change the speed and torque, change the direction of motion and change the form of motion.

3.Reducer

The reducer is a kind of power transmission mechanism, which uses the speed converter of gear to reduce the rotation number of motor to the required rotation number and obtain a structure with large torque.

Function of reducer:Reduce the speed and increase the output torque at the same time. The torque output ratio is multiplied by the motor output deceleration ratio, but it shall not exceed the rated torque of the reducer.At the same time, the inertia of the lo.ad is reduced to the square of the deceleration ratio.

4.Motor

WUXI ABK 3-Ton 3-Axis Welding Positioner Maintenance & Certification Guide

Comprehensive Maintenance Protocol

Proper maintenance of our 3-axis welding positioner ensures optimal performance in robotic welding cells and precision fabrication applications. Daily maintenance should include thorough removal of welding spatter, verification of lubrication levels in all tilting mechanism joints, and inspection of electrical connections. For automated production lines, we recommend implementing our patented laser alignment check procedure weekly to maintain ±0.5° positioning accuracy.

Scheduled Maintenance Requirements

-

Monthly:

-

Tighten all rotary table mounting bolts (85-95Nm torque)

-

Inspect worm gear reducer for backlash (<0.1mm tolerance)

-

Test emergency stop functionality

-

-

Quarterly:

-

Replace axis drive grease (Mobilith SHC 220 recommended)

-

Calibrate PLC control system parameters

-

Verify load cell accuracy in all three axes

-

-

Annual:

-

Complete bearing replacement in tilting mechanism

-

Overhaul servo motor brushes and encoders

-

Perform full laser tracker alignment verification

-

Performance Preservation Benefits

Following this maintenance regimen delivers:

✓ 40% longer service life for positioner components

✓ 50% reduction in unplanned downtime

✓ Consistent maintenance of 0.1mm repeatability in arc welding applications

✓ Preservation of CE safety certification compliance

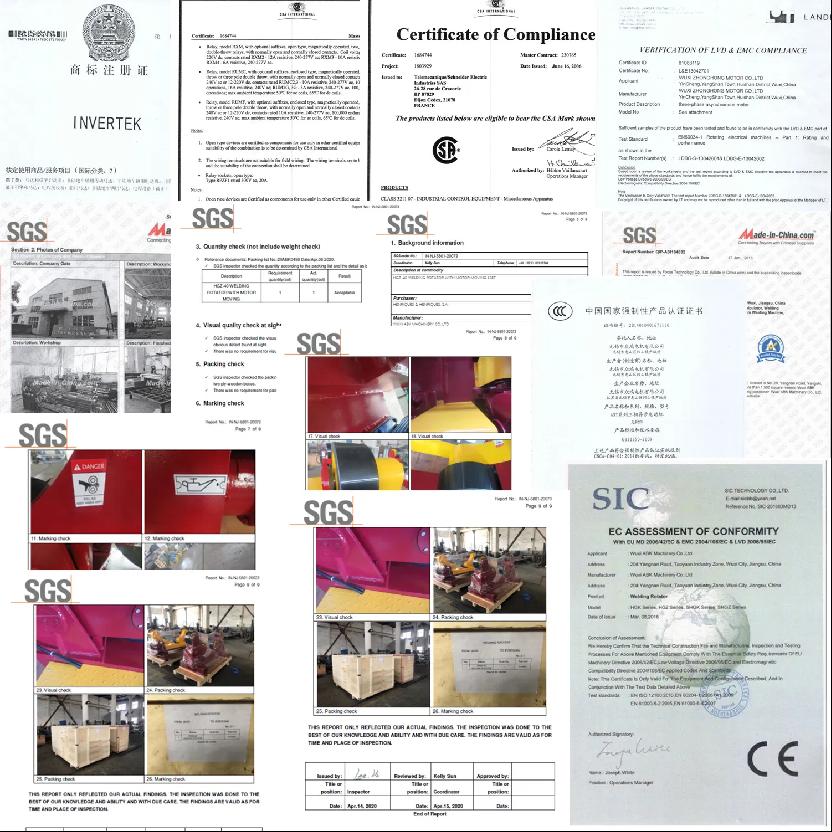

Advanced Certification & Technology

Our 3-ton positioner series meets:

-

ISO 12100-2010 machinery safety standards

-

ANSI/RIA R15.06 robotic integration requirements

-

ATEX Directive 2014/34/EU for explosive environments

Innovative Positioner Features

The WUXI ABK 3-axis system incorporates:

-

German-made harmonic drives in all rotational axes

-

Siemens S7-1200 PLC with 100+ preset welding programs

-

IP54-rated enclosures for harsh manufacturing environments

Why Choose WUXI ABK?

With 20+ years in welding automation, we provide 24/7 technical support, custom configurations, and 3-year core component warranties. Our 3-ton positioner is engineered for zero-defect welding in mission-critical industries.

Wuxi ABK Machinery Co.Ltd is a professional manufacturer of welding rotator in China. And our welding rotator mainly includes standard welding rotator, adjustable welding rotator, and special welding rotator. We can also provide our clients around the world with many other products including welding turntable, pile welding machine, wind tower production line, H beam welding line, pipe welding equipment, CNC cutting machine, grinding machine, roll forming machine, plate bending machine, etc. We have obtained ISO and CE certification, and we also offer OEM service.