200kg Welding Turntable

A heavy-duty welding turntable designed for 360° rotational welding of pipes, flanges, and small structures. Features 1-10 RPM adjustable speed, 200kg load capacity, and ±0.5° positioning accuracy. Ideal for manual welding and robotic welding integration. CE/ISO certified with servo motor drive for precision performance.

WUXI ABK Welding Equipment: Precision Rotation Solutions

Technical Advantages

✔ Programmable Rotation – Digital control maintains 0.1-1.2 RPM for various joining requirements

✔ Load Optimized – Standard 1-50 ton capacity with custom configurations available

✔ Adaptable Surface – Modular worktable accepts 800-6000mm diameter assemblies

✔ Precision Movement – ±0.5mm repeatability ensures joint accuracy

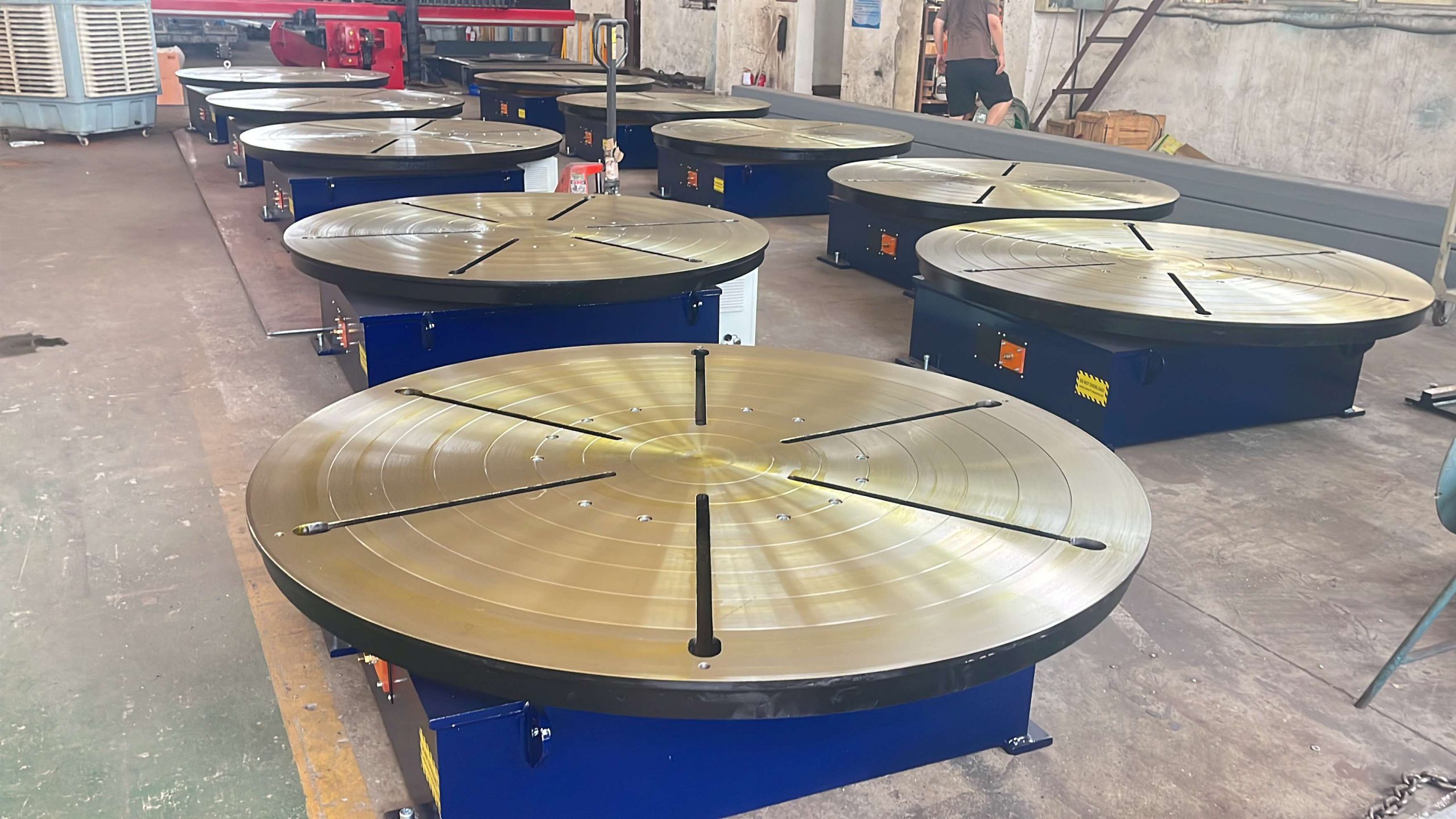

The WUXI ABK 200kg Welding Turntable is a precision-engineered rotary welding positioner designed for industrial fabrication of critical components. This robust welding automation solution excels in pressure vessel production, energy equipment manufacturing, structural steel welding, and marine construction applications, providing reliable workpiece rotation for consistent weld quality.

Key Features

-

Heavy-duty construction with industrial-grade bearings supporting 200kg payload capacity

-

Variable frequency drive system enabling 5-60 RPM speed control for optimal weld parameters

-

Interchangeable mounting plates (standard/flange) for flexible fixture compatibility

-

Safety-rated enclosures (IP54 optional) for hazardous workshop environments

Our welding turntables incorporate precision rotation technology with:

✓ <0.1° positional accuracy via servo feedback

✓ Integrated torque monitoring to prevent overload

✓ Modular design allowing custom surface treatments (e.g., copper plating for heat dissipation)

Custom Engineering Options

WUXI ABK delivers tailored welding solutions including:

-

Automated position tracking with encoder feedback

-

Real-time weld quality monitoring systems

-

Ergonomic HMI interfaces with preset welding programs

Manufacturing Standards

Every welding positioner undergoes:

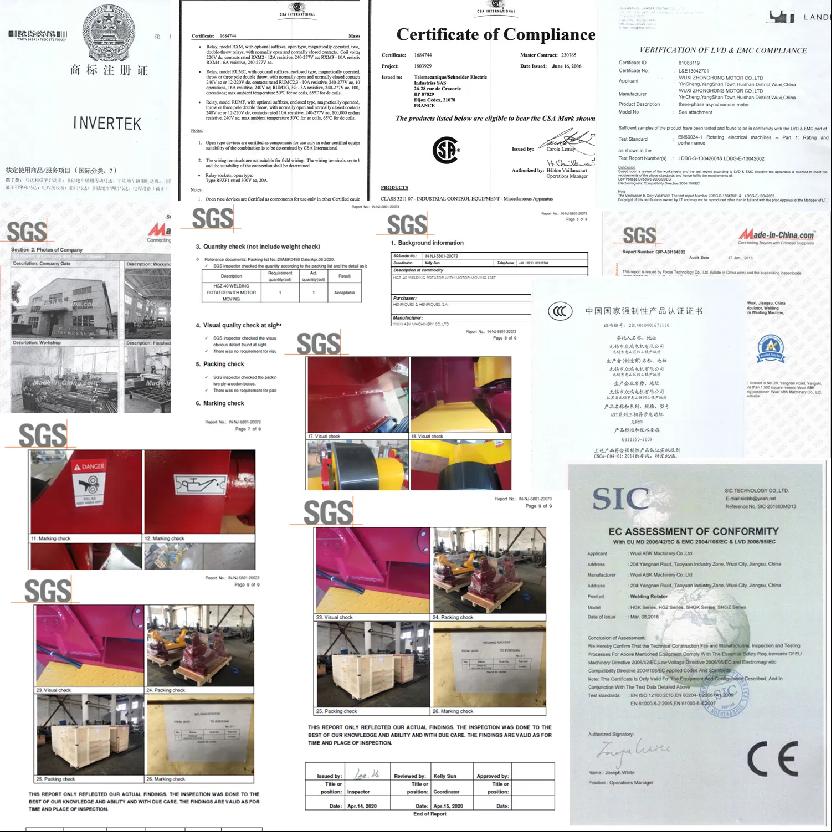

◆ ISO 9001-certified production

◆ 72-hour endurance testing

◆ Global CE/ASME compliance

◆ 3-year critical component warranty

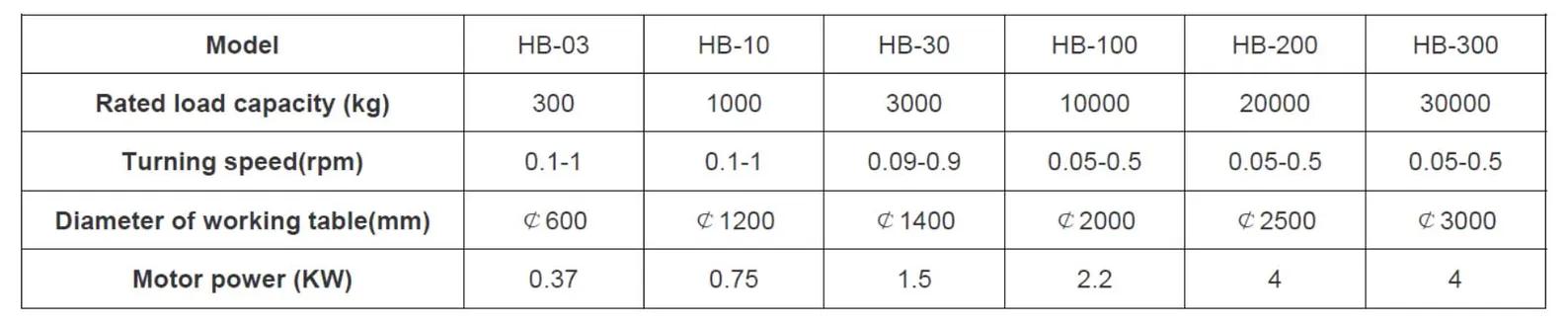

| Description of HB Series Welding Turntable: WUXI ABK Welding Equipment: Precision Rotation Solutions |

HB-02 | ||

| Load Capacity | (KG) | 200 | |

| Rotating Speed | (RPM) | 0.1-1 | |

| Worktable Size Diameter | (MM) | 600 | |

| Power | (KW) | 0.37 | |

| Power Supply | (V) | 50Hz 3ɸ | 380 (Determined according to customer needs) |

| Speed Regulating Type | AC Frequency Stepless Speed Regulation | ||

| Note: All specifications are of the standard equipment, that may be changed to suit the customers’ requirement. | |||

The WUXI ABK 200kg Welding Turntable is a precision rotating platform designed for efficient welding of small to medium workpieces, including pipes, flanges, and metal structures. Engineered for industrial welding applications, this welding positioner delivers 360° smooth rotation, allowing operators to weld all sides without repositioning. With adjustable speed control (1-10 RPM), it ensures perfect seam consistency for high-quality welds in fabrication workshops and production lines.

Key Features:

-

Heavy-duty construction supports up to 200kg (500kg optional) for stable operation

-

Direct drive system with inverter control for precise speed regulation

-

Motorized travel option enhances mobility in workshop environments

-

OEM customization available for specialized welding applications

Performance Advantages:

✓ 50% faster welding compared to manual methods

✓ Reduced labor costs with automated rotation

✓ Durable components for long-term reliability

✓ Easy integration with MIG, TIG, and robotic welding systems

Technical Specifications:

-

Load Capacity: 200kg (standard) / 500kg (optional)

-

Rotation Speed: 1-10 RPM (stepless adjustment)

-

Drive System: High-torque servo motor

-

Control Interface: User-friendly HMI panel

-

Power Supply: 220V/380V, 50/60Hz

Applications:

-

Pipe welding for plumbing and HVAC systems

-

Flange fabrication in oil and gas industries

-

Structural welding for metal frames and assemblies

-

Automotive and machinery parts production

Why Choose WUXI ABK?

-

20+ years of welding equipment manufacturing expertise

-

CE & ISO certified for quality assurance

-

24/7 technical support and customized solutions

Parameter list of conventional Welding Turntable

Features

1. Multi-Position T-Slot Worktable

6 heavy-duty T-slots (14mm width)

Max clamping force: 5000N per slot

360° adjustable positioning

2. Reinforced Steel Construction

6 high-rigidity support ribs

Deformation resistance <0.08mm/m²

Military-grade welding seams

3. Premium Worm Gear Transmission

Precision ground gear(ISO 5 grade accuracy)

Zero-backlash operation

10,000+ hour service life

4. Stepless Speed Regulation

Digital control panel

0.5-15 RPM variable range

±1% speed accuracy

5. Intelligent Control System

One-touch operation interface

Automatic lubrication reminders

IP54 protection rating

6. Stabilized Heavy-Duty Base

200mm thick steel plate foundation

8-point leveling system

Vibration absorption <0.01mm

Performance Advantages:

✓ 40% faster setup time

✓ 60% reduction in workpiece deformation

✓ 30% longer equipment lifespan

1. Slewing bearing

Slewing bearing is the force basic element of machine, which requires relative rotation between all two parts and bears axial force, radial force and overturning moment at the same time.Its basic function is to use bolts to fix it on the upper and lower supports of mechanical equipment to transmit force and drive so as to realize the relative rotation between the two parts of mechanical equipment.Rotary support generally has installation holes, internal or external gears, lubrication holes and sealing devices. It has the characteristics of compact structure, light weight, good structural steel, smooth operation, high accuracy, safety and reliability.

Slewing bearing is a basic part of mechanical equipment and widely used in various industries of national economy. It is widely used in construction machinery, port machinery, metallurgical machinery, mining machinery, petroleum machinery, chemical machinery, medical equipment, ship machinery, light industrial machinery, environmental protection machinery, entertainment equipment, transportation machinery equipment.Swing supports are increasingly used in energy-saving and environmental protection projects, such as wind turbines that require a variety of precision pole swing support kits.

- Gear

Gear is a wheel like mechanical part which transmits the torque by the engagement of teeth. Through the transmission with other toothed mechanical parts (such as another gear, Dao rack and worm), the gear can change the speed and torque, change the direction of motion and change the form of motion.

3.Reducer

The reducer is a kind of power transmission mechanism, which uses the speed converter of gear to reduce the rotation number of motor to the required rotation number and obtain a structure with large torque.

Function of reducer:Reduce the speed and increase the output torque at the same time. The torque output ratio is multiplied by the motor output deceleration ratio, but it shall not exceed the rated torque of the reducer.At the same time, the inertia of the lo.ad is reduced to the square of the deceleration ratio.

4. Motor

Welding Turntable Maintenance Guidelines

Core maintenance content

Daily maintenance-cleaning welding slag, checking lubrication and electrical safety.

Regular maintenance-tighten bolts, check transmission mechanism and test safety function.

Deep maintenance-annual replacement of worn parts, re-lubrication and system calibration

Fault early warning-Stop immediately when abnormal noise/uneven rotation occurs.

Maintain value

- Extend the service life of equipment by more than 30%

- Reduce sudden downtime

- Ensure the stability of welding accuracy.

Product certification

Step into the future of welding technology with our cutting-edge solutions.

From automated processes to intuitive controls, our products are at the forefront of innovation, providing you with the tools you need to stay ahead in today’s competitive market!

Wuxi ABK Machinery Co.Ltd is a professional manufacturer of welding rotator in China. And our welding rotator mainly includes standard welding rotator, adjustable welding rotator, and special welding rotator. We can also provide our clients around the world with many other products including welding turntable, pile welding machine, wind tower production line, H beam welding line, pipe welding equipment, CNC cutting machine, grinding machine, roll forming machine, plate bending machine, etc. We have obtained ISO and CE certification, and we also offer OEM service.