10T Fit Up Rotator

10 Tons Fit Up Rotator

CONVENTIONAL WELDING ROTATORS

FIT UP Series

Conventional Rotators are designed to aid in the welding of cylindrical vessels or columns.

| · Trusted design | · Reliable Quality |

| · Renowned parts | · Inverter control |

| · Direct drive system | · Motorised travel option |

| · Build to order custom design | · OEM

|

CONVENTIONAL WELDING ROTATORS

FIT UP Series

Conventional Rotators are designed to aid in the welding of cylindrical vessels or columns.

| · Trusted design | · Reliable Quality |

| · Renowned parts | · Inverter control |

| · Direct drive system | · Motorised travel option |

| · Build to order custom design | · OEM |

- Summary

- Equipment composition

System Overview

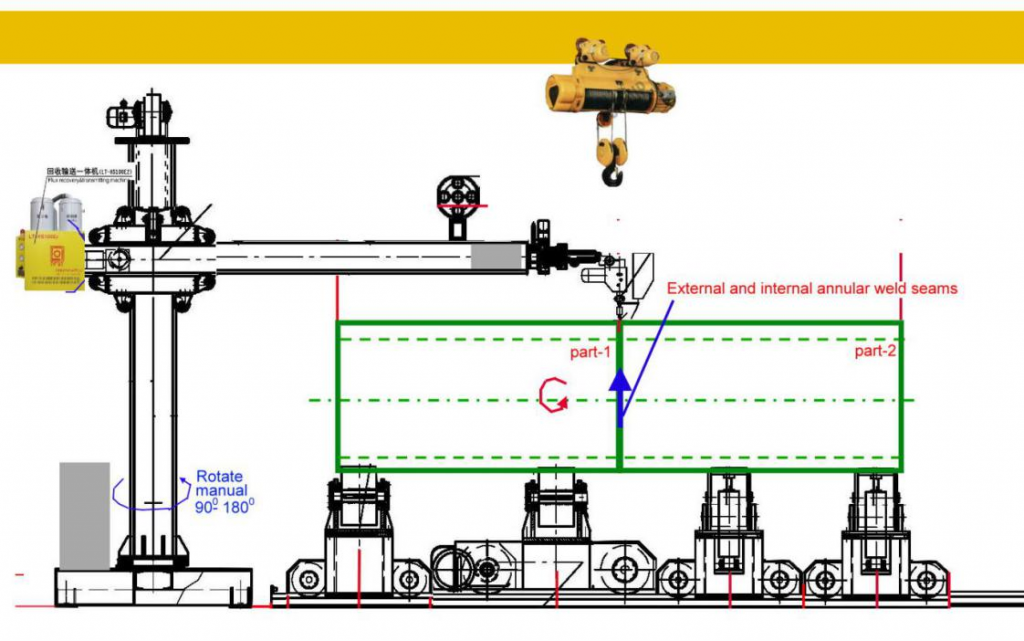

The WUXI ABK 10T Fit-Up Rotator represents an advanced solution for cylindrical vessel assembly and welding applications, specifically engineered for pressure vessel fabrication, wind tower production, and large-diameter pipe welding. This integrated system combines precision mechanical components with intelligent control technology to streamline the fit-up and welding process for industrial containers.

Core Components

-

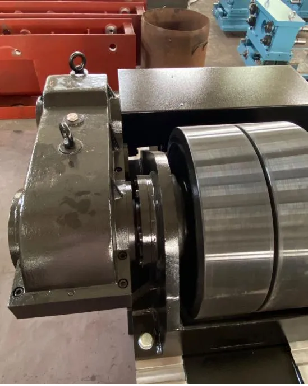

Driving Roller Frame:

-

7.5kW AC motor with precision reducer

-

Frequency conversion control system (0.1-1.2m/min adjustable)

-

50-ton load capacity (customizable to 100 tons)

-

Hydraulic Assembly Roller Frames (2 sets):

-

Integrated hydraulic lifting system (±0.5mm positioning accuracy)

-

Track movement mechanism for precise alignment

-

Anti-creep stabilization technology

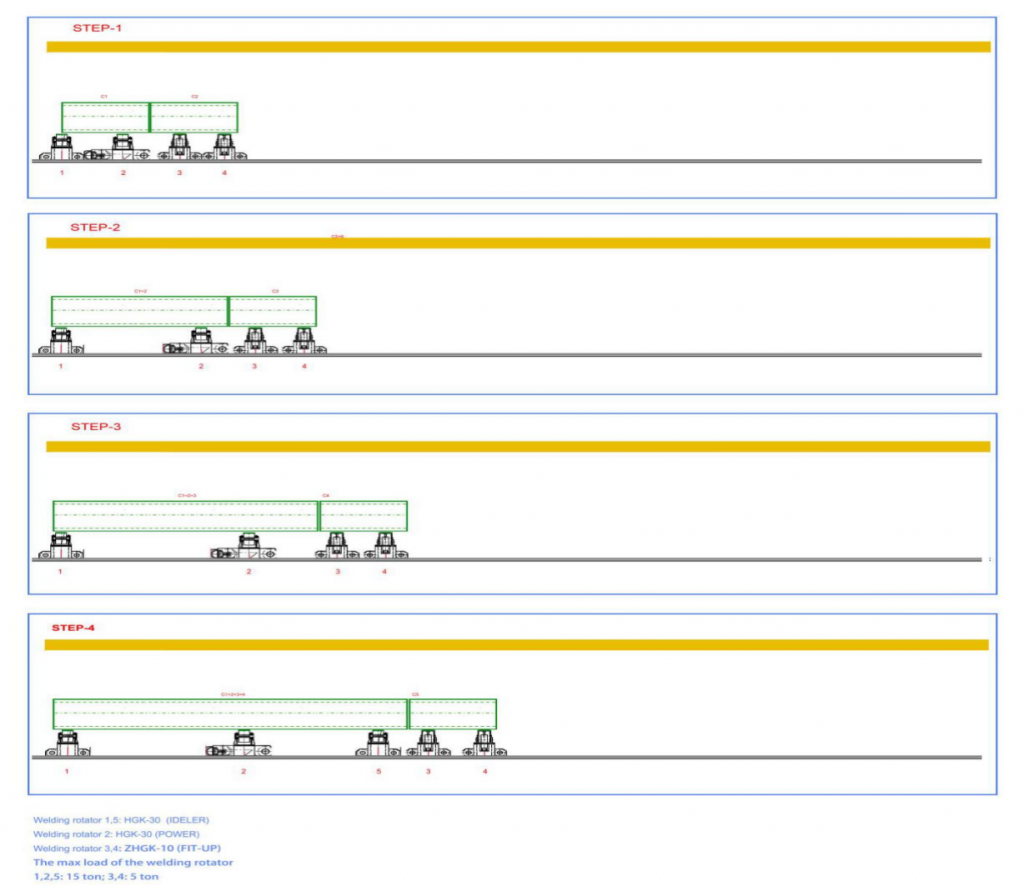

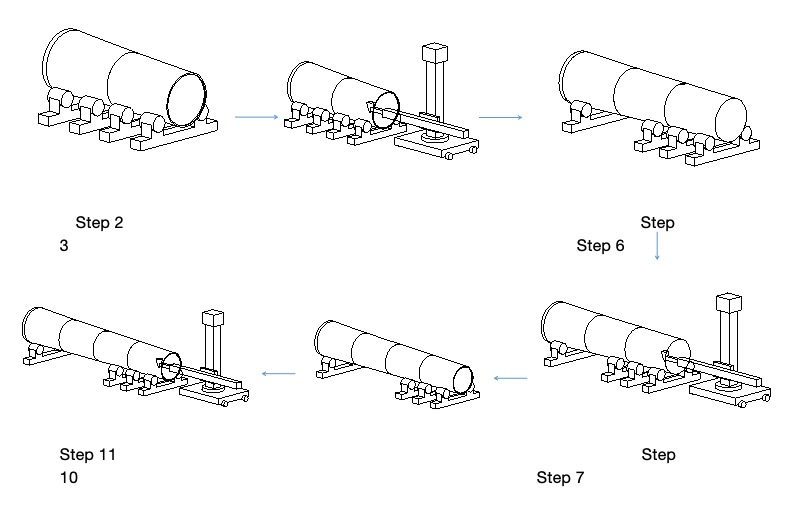

Workflow Process

The system operates through three optimized phases:

Phase 1: Segmented Positioning

The primary vessel section is positioned on the driving/driven roller frames, while secondary sections are loaded onto the hydraulic assembly frames. Our patented alignment system ensures perfect concentricity before welding commences.

Phase 2: Precision Assembly & Welding

-

Hydraulic frames move along tracks for millimeter-perfect butt joint alignment

-

Welding manipulators complete both inner and outer circumferential seams

-

Real-time monitoring of weld seam consistency

Phase 3: Continuous Expansion

The process repeats sequentially until complete vessel assembly is achieved, with the driving roller frame automatically indexing each new section into position.

Technical Advantages

-

Variable Frequency Control: Stepless speed regulation from 0.1 to 1.2m/min

-

Hydraulic Precision: 0.5mm assembly accuracy for perfect joint matching

-

Adaptive Capacity: Handles 1.5-6m diameter vessels (expandable to 8m)

-

Smart Welding Integration: Compatible with all major welding manipulator brands

Safety Systems

✓ Dual-circuit overload protection

✓ Emergency braking with <0.5m stopping distance

✓ Laser-based anti-channeling detection

✓ IP54 rated electrical components

Operational Parameters

| Specification | Metric |

|---|---|

| Max Load Capacity | 50 tons (standard) |

| Diameter Range | 1.5-6m |

| Speed Range | 0.1-1.2m/min |

| Positioning Accuracy | ±0.5mm |

| Power Requirement | 380V/50Hz |

Industry Applications

-

Pressure vessel circumferential seam welding

-

Wind turbine tower section assembly

-

Petrochemical storage tank fabrication

-

Large-diameter pipeline girth welding

-

Shipbuilding component manufacturing

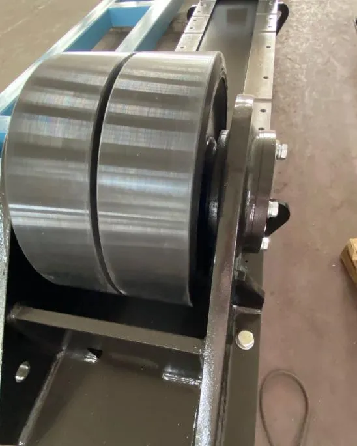

Wheel introduction

Polyurethane wheels offer exceptional abrasion resistance, versatile processing, wide applicability, and superior resistance to oil, ozone, aging, radiation, and low temperatures. They also provide strong adhesion, excellent sound transmission, biocompatibility, and blood compatibility.

Motor introduction

Welding Rotator Maintenance Guidelines

Clean the welding rotator before use. Keep the rubber rollers away from oils and high temperatures to prevent aging. It’s recommended that a designated person operates and maintains the equipment.

Ensure the speed reducer is filled with 30# engine oil before starting, especially when the temperature is below 0ºC.

Replace the oil in the speed reducer after the first month of use. Afterward, change the oil every six months.

Do not use the roller bed as a welding ground to avoid damaging the bearings.

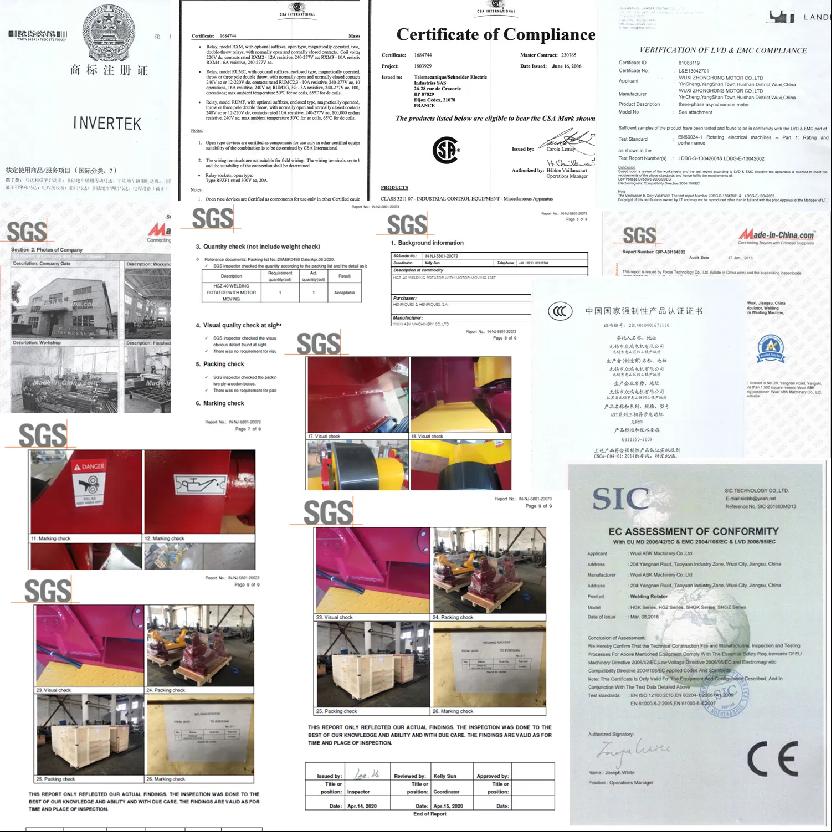

Top quality rotator manufacturer

1.With over 20 years of specialized experience in manufacturing self-aligning rotators.

2.Our products feature a bearing capacity that ranges from 5 tons to 400 tons.

3.We provide CE and ISO certifications, ensuring compliance with stringent sub-regulations. Additionally.

4.We offer a one-year warranty and free wearing parts.

5.Our highly skilled technical team is dedicated to supporting you and your large-scale projects, such as wind turbine welding.

Wuxi ABK Machinery Co.Ltd is a professional manufacturer of welding rotator in China. And our welding rotator mainly includes standard welding rotator, adjustable welding rotator, and special welding rotator. We can also provide our clients around the world with many other products including welding turntable, pile welding machine, wind tower production line, H beam welding line, pipe welding equipment, CNC cutting machine, grinding machine, roll forming machine, plate bending machine, etc. We have obtained ISO and CE certification, and we also offer OEM service.