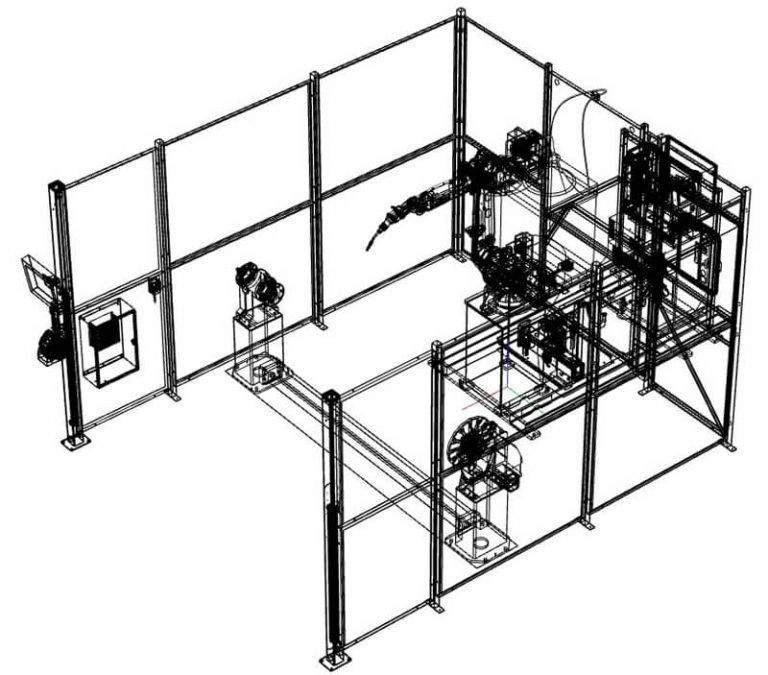

1.5 ton Head and Tail Positioner

WUXI ABK 1.5-Ton Head & Tail Positioner is a precision welding solution for small to medium workpieces. This compact yet robust positioner features ±0.5° accuracy, 0.1-2 RPM speed control, and universal chuck mounting. Ideal for pipe welding and structural fabrication, it offers CE/ISO certification with 18-month warranty.

The HBT Series Welding Positioner, developed by WUXI ABK, combines advanced domestic and international technologies with practical user insights. Its sleek, compact design ensures high precision, reliable performance, and easy operation, making it a preferred choice for industrial applications.

| Max. loading capacity | 15000 kg |

| Lifting up | 2000 mm |

| Height of the rotation axis | 750 –2750 mm |

| Horizontal stroke of the fixation device | 400 mm |

| Lifting up speed | 1.3 m/min |

| Rotation speed | 1.2 rpm |

| Rotation angle | 360° |

| Welding positioner type | positioner with lifting devices |

| Construction | double column |

| Lifting up drive | electromechanic |

| Positioning Accuracy | ±2мм |

| Voltage | 380 V |

| Power frequency | 50 Hz |

| Note: All specifications are of the standard equipment, that may be changed to suit the customers’ requirement. | |

1. Slewing bearing

The slewing bearing is a critical load-bearing component that enables relative rotation between machine parts while simultaneously handling axial, radial, and overturning moment forces. Its compact and lightweight design, made from high-strength alloy steel, ensures smooth operation with high precision (±0.05° rotation accuracy) and long service life. Key configurations include mounting bolt holes, optional internal/external gears, lubrication ports, and sealing systems for enhanced reliability. With a diameter range of 300–5000mm and load capacity up to 50,000kN, it is widely used in construction machinery, wind turbines, cranes, and military equipment. Custom designs are available for specialized applications.

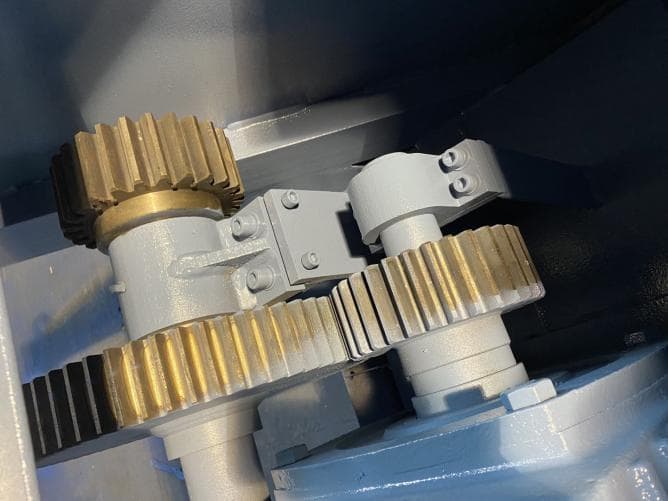

- Gear

1). Reverse gear

Generally, the turning angle of the turning gear is 0 °to 90 °. The function of displacement is achieved by turning the table.

2). Reverse gear

Gears are toothed mechanical components that transmit torque through meshing engagement with other gear elements like racks, worms or additional gears, enabling precise control over power transmission by modifying speed/torque ratios, redirecting motion paths, and converting motion types (e.g., rotary to linear). Their interlocking teeth design provides reliable force transfer while allowing for customizable mechanical advantage in various industrial applications.

3.Reducer

Gear reducers are mechanical power transmission devices that utilize precision gear systems to reduce input speed while proportionally increasing output torque, with the output torque being the product of motor torque and gear ratio (without exceeding the reducer’s rated capacity). These systems simultaneously decrease load inertia by the square of the reduction ratio, enabling optimized power conversion for various industrial applications through efficient gear engagement.

WUXI ABK 1.5-Ton Head & Tail Positioner Maintenance Guide

Proper maintenance ensures optimal performance of your welding positioner in pipe fabrication and structural welding applications. For daily operation, remove welding slag and verify lubrication levels while inspecting electrical connections. Monthly maintenance should include bolt torque checks (85-95Nm for M12 fasteners), gear reducer inspection, and safety limit switch testing.

Critical Maintenance Procedures:

-

Annual bearing replacement and system recalibration

-

Grease replenishment for worm gear drives (Mobilux EP 2 recommended)

-

Encoder calibration to maintain ±0.5° positioning accuracy

Performance Benefits:

✓ 30% extended service life for precision turntable components

✓ 50% reduction in unplanned downtime

✓ Consistent welding seam quality with <0.3mm runout

Fault Prevention:

Immediately stop operation if detecting:

• Abnormal gear noise (indicating lubrication issues)

• Uneven rotation (suggesting bearing wear or misalignment)

Certification & Innovation:

Our CE/ISO certified positioner features:

-

Automated welding integration via PLC interfaces

-

Ergonomic controls for small batch production

-

Modular design simplifying component replacement

Wuxi ABK Machinery Co.Ltd is a professional manufacturer of welding rotator in China. And our welding rotator mainly includes standard welding rotator, adjustable welding rotator, and special welding rotator. We can also provide our clients around the world with many other products including welding turntable, pile welding machine, wind tower production line, H beam welding line, pipe welding equipment, CNC cutting machine, grinding machine, roll forming machine, plate bending machine, etc. We have obtained ISO and CE certification, and we also offer OEM service.