Quality Challenges of Traditional Coating Methods

In the pipeline workshop of a major shipyard in Jiangsu, workers were struggling with coating quality issues on a batch of fuel pipelines. Using traditional manual spraying methods, the pipe surfaces frequently showed defects like sagging and orange peel texture. X-ray inspection revealed uneven coating thickness with variations up to ±50 microns. Quality reports showed the first-pass qualification rate for these pipelines was only 82%, with rework delaying the schedule by 15 days and incurring additional repair costs of 370,000 RMB.

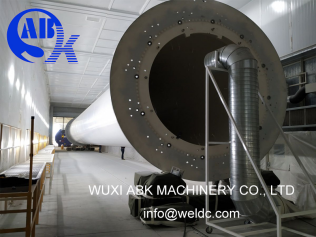

This predicament is common in shipbuilding. As the “vascular system” of vessels, pipeline coating quality directly impacts corrosion resistance and service life. Traditional fixed-position spraying requires manual pipe rotation by workers – inefficient and inconsistent in coating uniformity.

The Technological Revolution of Paint Roller Racks

Advantages of Automated Coating

The situation was completely transformed after adopting pipeline coating rotary systems. Engineering cases from a Shanghai marine equipment supplier showed that implementing automated coating turntables significantly improved pipeline coating quality. The system uses variable frequency motors to drive rollers, rotating pipes steadily at 2-10 RPM while coordinating with high-pressure airless spray guns to control coating thickness variation within ±10 microns.

Breakthrough Technologies

More importantly, these welding-spraying integrated positioning devices ensure uniform coating coverage on every angle of pipes, completely eliminating missed spots at elbows and welds. At an LNG vessel construction project in Guangdong, the shipyard used heavy-duty pipeline rotating supports for fuel system coating. Field data showed the new process reduced coating time per pipe from 25 minutes to just 8 minutes compared to manual spraying.

Analysis of Practical Application Results

Significant Quality Improvements

Test data indicates the new process increased paint utilization from 65% to 92%, saving over 800,000 RMB annually in coating materials. Most remarkably, the first-pass qualification rate jumped from 82% to 98.3%, passing DNV’s stringent inspections.

Economic Benefits of Efficiency Gains

The successful application of these intelligent coating positioning equipment relies on several technological breakthroughs. First is the precision speed control system, with PLC programming to match rotation parameters to different pipe diameters and coating characteristics. Second is the special anti-drip design featuring collection trays under rollers that prevent paint waste while maintaining clean workspaces.

Key Considerations for Equipment Selection

Technical Parameter Selection

For shipyards considering upgrades, selecting appropriate coating rotary supports requires focusing on three key indicators: load capacity with 20% safety margin, corrosion resistance passing 1000-hour salt spray tests, and preferably control systems with parameter memory functions.

ROI Case Studies

Procurement experience from a Zhejiang shipyard shows that investing 500,000 RMB in mid-sized equipment typically achieves payback within 12-18 months through savings in coatings and labor costs. With advancing smart manufacturing, new-generation digital coating turntables are now incorporating IoT technology.

Future Development Trends

Smart Upgrade Directions

By real-time monitoring of rotation speed, paint flow and correlating this data with quality inspection results, these systems are helping shipyards build more scientific coating process databases. Practices at a state-owned shipyard demonstrate this data-driven optimization method can further improve coating consistency by 15%.

New Industry Competition Requirements

For shipyard managers troubled by pipeline coating quality issues, now is the ideal time for technological upgrades. Professional coating positioning system suppliers can not only provide customized equipment but also assist with process validation and operator training.

Conclusion: The Necessity of Strategic Investment

In today’s increasingly competitive shipbuilding market, pipeline coating quality has become a key indicator of a shipyard’s technical capability. Investing in advanced paint roller rack systems not only solves immediate quality issues but represents a strategic move to enhance core competitiveness. From a long-term perspective, this is no longer just a cost consideration but a necessary investment for business sustainability.

Keywords:

coating rotary supports,digital coating turntables, coating positioning system, positioning equipment