Automatic fit up rotator 20Tons

Der WUXI ABK 20-Tonnen Fit Up Rotator bietet eine präzise Ausrichtung für die Fertigung mittelgroßer Behälter mit einer Positioniergenauigkeit von ±0,8 mm und einer einstellbaren Rotation von 0,2-1,5 m/min. Dieses robuste Schweißpositioniergerät kann Werkstücke mit einem Durchmesser von 1-4 m und einer Tragkraft von 20 Tonnen bearbeiten. Es verfügt über integrierte Durchbiegungsschutzmechanismen und ist mit automatisierten Schweißsystemen für die effiziente Fertigung von Druckbehältern und Baustahl kompatibel.

20 Tons Fit Up Rotator

CONVENTIONAL WELDING ROTATORS

FIT UP Series

Conventional Rotators are designed to aid in the welding of cylindrical vessels or columns.

| · Trusted design | · Reliable Quality |

| · Renowned parts | · Inverter control |

| · Direct drive system | · Motorised travel option |

| · Build to order custom design | · OEM

|

CONVENTIONAL WELDING ROTATORS

FIT UP Series

Conventional Rotators are designed to aid in the welding of cylindrical vessels or columns.

| · Trusted design | · Reliable Quality |

| · Renowned parts | · Inverter control |

| · Direct drive system | · Motorised travel option |

| · Build to order custom design | · OEM |

- Summary

- Equipment composition

WUXI ABK 20-Ton Fit Up Rotator Product Introduction

The WUXI ABK 20-Ton Fit Up Rotator is a precision-engineered welding positioning system designed for cylindrical vessel fabrication, tank segment assemblyund large-diameter pipe welding. This industrial rotator system combines variable frequency speed control, hydraulic lifting adjustmentund track-guided movement to streamline fit-up welding processes in pressure vessel manufacturing und structural steel fabrication.

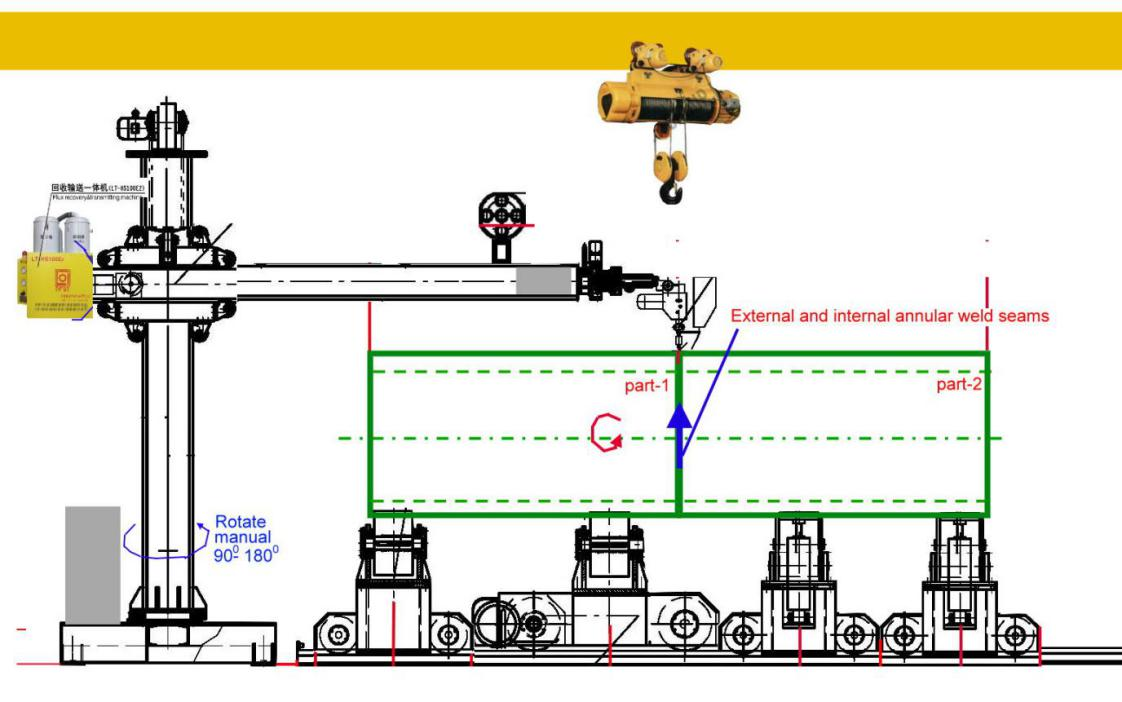

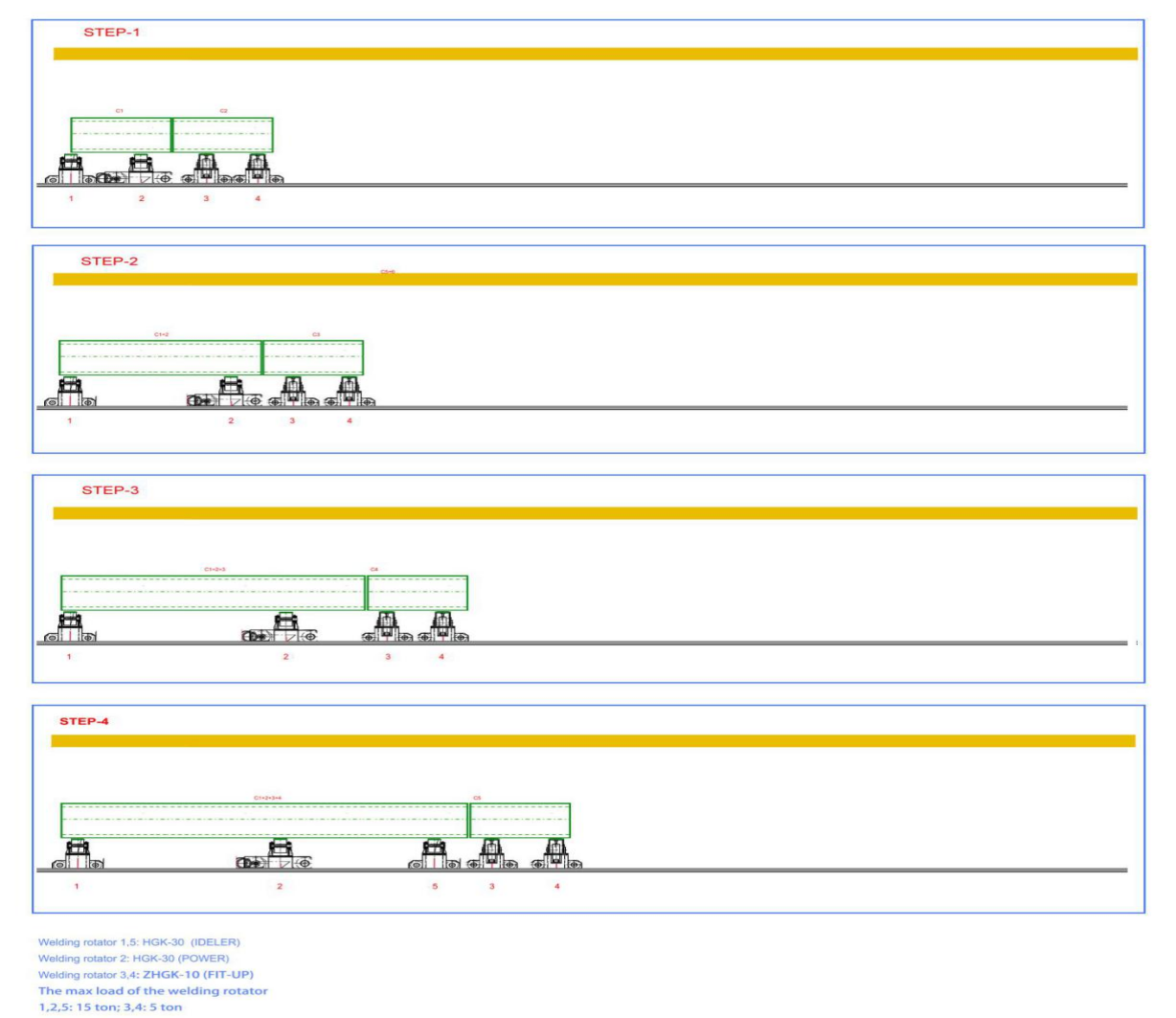

Core Components & Workflow

The system comprises:

-

Driving roller frame mit AC motor + reducer (0.1–1.2 m/min stepless speed regulation)

-

Driven roller frame for stable rotation

-

Hydraulic assembly roller frames (2 sets) mit 0.5mm precision alignment und track mobility

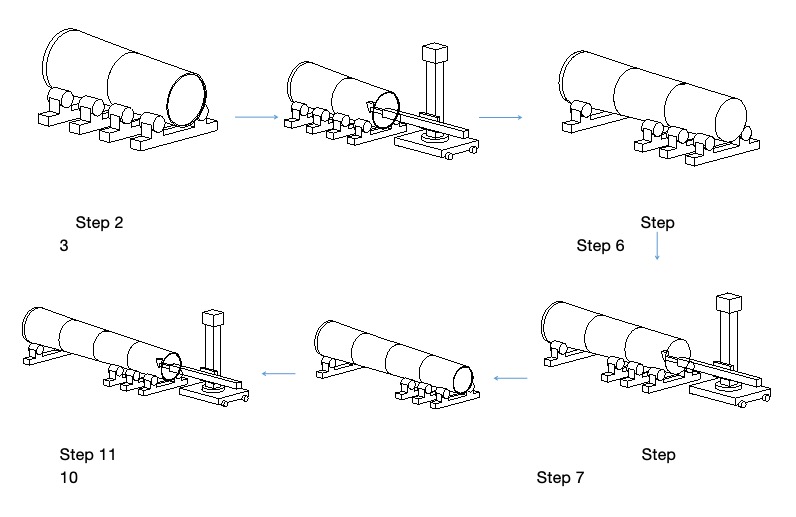

Operational Process:

-

Segmented Positioning: Place the first barrel on the driving/driven roller frames, and the second on hydraulic roller frames.

-

Assembly & Welding: The frames move along tracks for butt joint alignment; the hydraulic lifter fine-tunes position before tack welding. A Schweißmanipulator completes inner/outer seam welding.

-

Continuous Expansion: Repeat to assemble large-diameter vessels (1.5–6m) segment by segment.

Technical Advantages

-

50-ton max load (customizable for schwere Fabrikation)

-

Hydraulic precision: ±0.5mm fit-up accuracy

-

Automation-ready: Compatible with welding robots und manipulators

-

Safety systems: Overload protection, emergency brakingund anti-skid limits

Applications

Ideal for:

-

Pressure vessel und storage tank construction

-

Wind tower und offshore platform fabrication

-

Pipeline girth welding

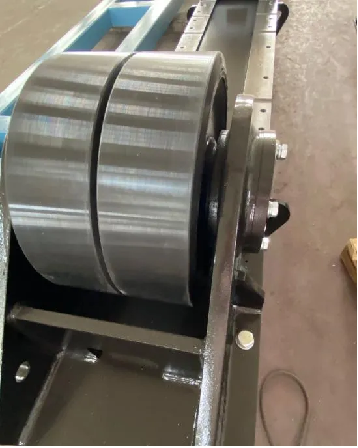

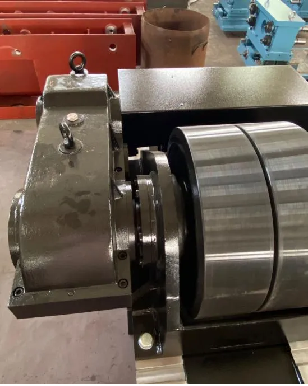

Wheel introduction

Polyurethane wheels offer exceptional abrasion resistance, versatile processing, wide applicability, and superior resistance to oil, ozone, aging, radiation, and low temperatures. They also provide strong adhesion, excellent sound transmission, biocompatibility, and blood compatibility.

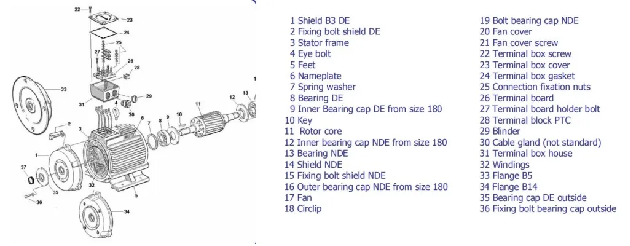

Motor introduction

Welding Rotator Maintenance Guidelines

Clean the welding rotator before use. Keep the rubber rollers away from oils and high temperatures to prevent aging. It’s recommended that a designated person operates and maintains the equipment.

Ensure the speed reducer is filled with 30# engine oil before starting, especially when the temperature is below 0ºC.

Replace the oil in the speed reducer after the first month of use. Afterward, change the oil every six months.

Do not use the roller bed as a welding ground to avoid damaging the bearings.

Top quality rotator manufacturer

1.With over 20 years of specialized experience in manufacturing self-aligning rotators.

2.Our products feature a bearing capacity that ranges from 5 tons to 400 tons.

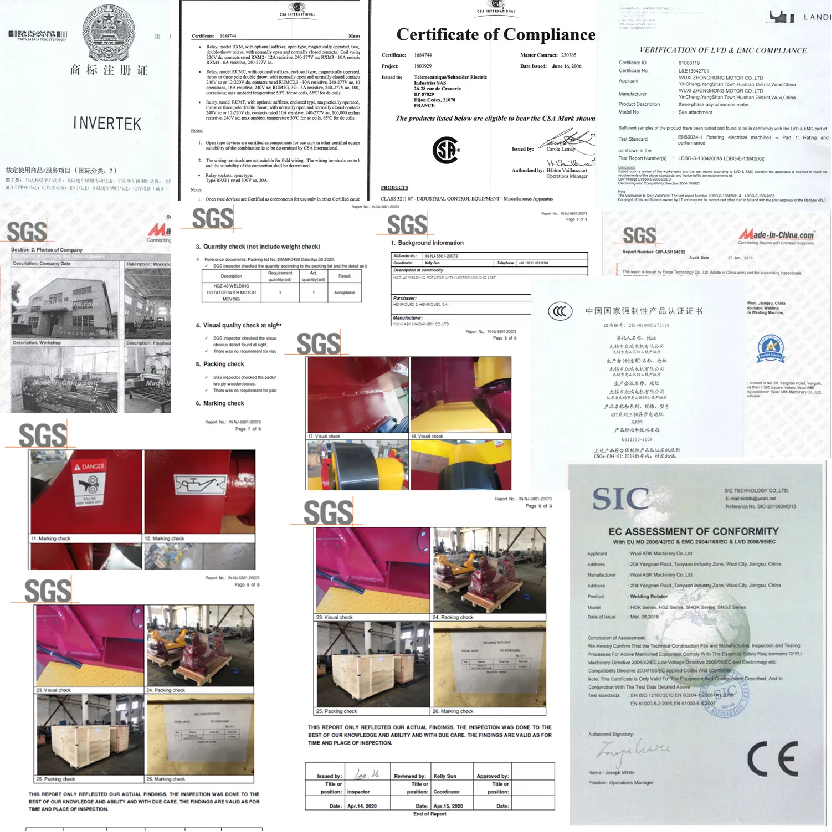

3.We provide CE and ISO certifications, ensuring compliance with stringent sub-regulations. Additionally.

4.We offer a one-year warranty and free wearing parts.

5.Our highly skilled technical team is dedicated to supporting you and your large-scale projects, such as wind turbine welding.

Wuxi ABK Machinery Co.Ltd is a professional manufacturer of welding rotator in China. And our welding rotator mainly includes standard welding rotator, adjustable welding rotator, and special welding rotator. We can also provide our clients around the world with many other products including welding turntable, pile welding machine, wind tower production line, H beam welding line, pipe welding equipment, CNC cutting machine, grinding machine, roll forming machine, plate bending machine, etc. We have obtained ISO and CE certification, and we also offer OEM service.