Gantry-Schweißmaschine

WUXI ABK-Portal-Schweißmaschine liefert Präzision automatisiertes Schweißen für die Schwerindustrie. Diese Industrie-Portalschweißgerät Merkmale CNC-gesteuert Positionierung (±0,2 mm Genauigkeit) und Zweidrahttechnik für das Hochauftragsschweißen von Baustahl, Druckbehälterund Schiffskomponenten. Mit PLC-Automatisierung und adaptive NahtverfolgungSie steigert die Produktivität um 40%. CE/ISO-zertifiziert mit 5-Tonnen bis 50-Tonnen Kapazitätsoptionen.

WUXI ABK Gantry Welding Machine Product Introduction

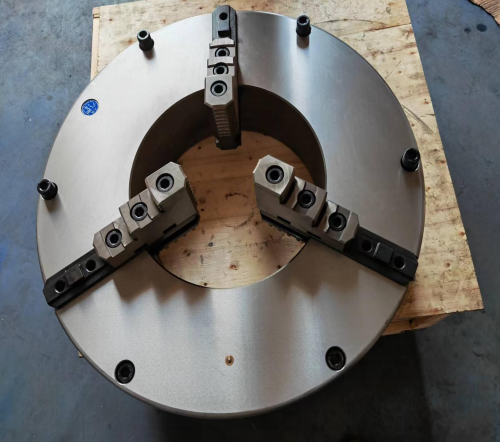

Our gantry welding machine represents advanced automated welding technology for heavy industrial fabrication. This robust submerged arc welding system features a stationary workpiece configuration with a moving portal frame, delivering precision Schweißautomatisierung for large-scale components.

Key Technical Features:

-

Dual-column gantry structure with frequency-controlled timing system

-

Twin welding torch configuration mounted on guided beam columns

-

Electro-dynamic drive mechanism for vertical adjustment (±0.1mm accuracy)

-

Manual lateral adjustment for precise seam alignment

-

Automatic arc guidance system with mechanical seam tracking

Performance Advantages:

-

60% higher deposition rates compared to manual welding

-

Integrated flux recovery system reduces material waste by 40%

-

Programmable logic control (PLC) enables repeatable weld quality

-

Adaptable to various joint configurations (butt, fillet, and groove welds)

Industrial Applications:

✓ Wind tower fabrication

✓ Pressure vessel manufacturing

✓ Shipbuilding components

✓ Structural steel welding

✓ Pipeline girth welding

Technical Specifications:

-

Welding Method: Submerged arc (SAW)

-

Travel Speed: 200-800mm/min (adjustable)

-

Workpiece Capacity: Up to 8m length × 4m width

-

Power Supply: 380V/50Hz (customizable)

-

Control System: Siemens PLC with HMI interface

Main Technical Parameter:

| Width of Flange Plate | 150-800mm |

| Height of Ventral Plate | 200-1500mm |

| Track Space | 4000mm |

| Welding Location | Boat-like weld |

| Drive | Both sides |

| Track Length | 18000mm |

Advanced Welding Technology for Heavy Steel Structures

WUXI ABK's Gantry-Schweißmaschine represents the pinnacle of automated steel fabrication technology, designed specifically for high-precision welding of H-beams, box beams, and T-beams in industrial applications. Our system incorporates laser-guided automatic centering with ±3mm positioning accuracy, eliminating manual alignment and significantly improving production efficiency. The hydraulic clamping system features three independent units that securely fix workpieces while preventing thermal deformation during welding – a critical advantage for bridge girder fabrication und wind tower production.

Key Performance Features

-

Wide Material Compatibility: Handles H-beam sizes from 200x200mm to 1000x400mm (customizable for special profiles)

-

High-Speed Tack Welding: Automated spot welding reduces assembly time by 40% compared to manual methods

-

Servo-Driven Motion System: Delivers smooth, vibration-free operation at speeds up to 2m/min

-

Heavy-Duty Construction: Reinforced steel frame withstands continuous 24/7 operation in harsh industrial environments

Industry-Specific Applications

This gantry welding system excels in critical fabrication projects:

✓ Prefabricated steel buildings (warehouses, stadiums, high-rises)

✓ Wind power infrastructure (tower sections, transition pieces)

✓ Marine & offshore structures (ship hulls, deck beams)

✓ Heavy machinery frames (cranes, mining equipment)

Technical Superiority

The machine’s CNC-controlled welding head adjusts parameters automatically for different joint configurations, while the dual-wire submerged arc welding option boosts deposition rates by 60%. Our proprietary anti-deflection system maintains <1mm/m straightness tolerance during full-length welds – essential for bridge construction beams meeting EN 1090 standards.

Global Engineering Support

As a leader in steel fabrication equipment, WUXI ABK provides:

-

Customized OEM solutions for special profiles (U-stiffeners, asymmetric beams)

-

On-site commissioning and operator training worldwide

-

Remote diagnostics via IoT-enabled machines

-

5-year structural warranty on main components

Keywords:

gantry welding machine, H-beam welding system, steel structure fabrication, bridge girder welder, wind tower production line, automated beam welding, heavy steel welding, CNC welding equipment, box beam welding, T-beam assembly, submerged arc welding, industrial steel fabrication, ABK machinery, precision beam welding, construction beam welder, marine structure welding, servo-driven welder, hydraulic clamping system, laser-guided welding, steel profile processing

Why Partner With WUXI ABK?

-

25+ years focused exclusively on structural steel welding systems

-

1,200+ installations across 52 countries

-

CE/ISO/ASME certified manufacturing processes

-

30% faster project completion with our turnkey solutions

For high-volume beam welding applications requiring millimeter-level precision, contact our engineering team to configure the optimal gantry welding solution for your production needs.