Манипулятор для сварки

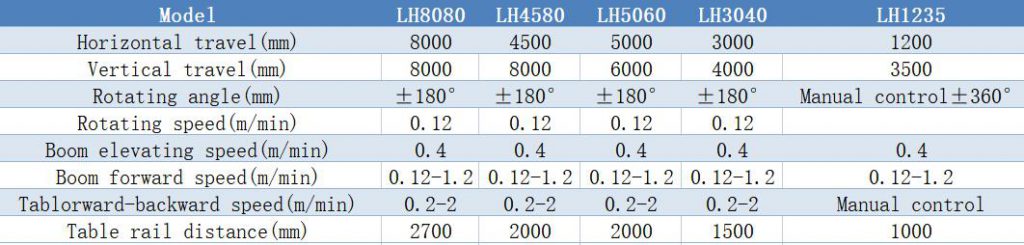

Технические параметры сварочного манипулятора (манипулятора с колонной):

Основная структура

Колонна+крестовина+направляющее сиденье+мобильная тележка

Состав полного множества

* Колонка

* Boom

* База

* Седло

* Подъемная система

* Система расширения

* Система вращения

* Блокировка вращения

* Тип перемещения и вращения

* Анти-капля

* Угол головы

* Каретка на стреле

* Power-слайды

* Система управления

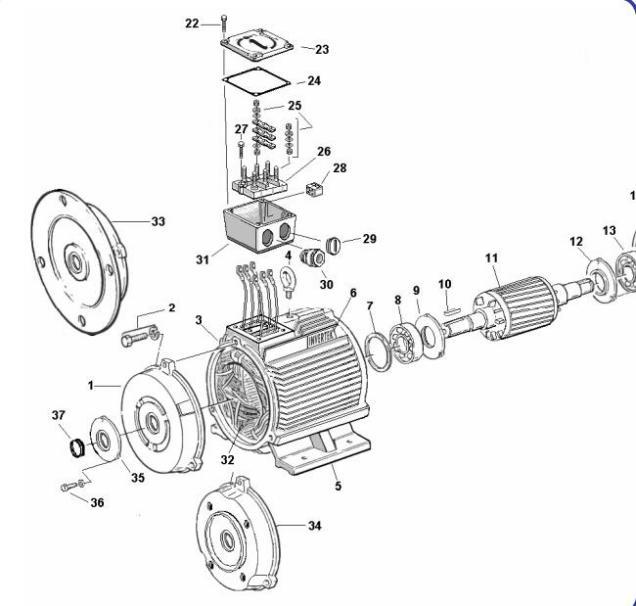

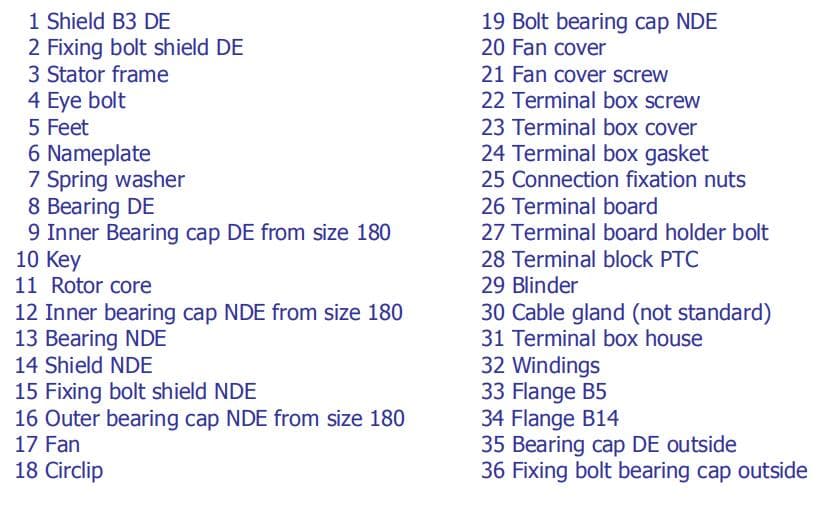

- Двигатель

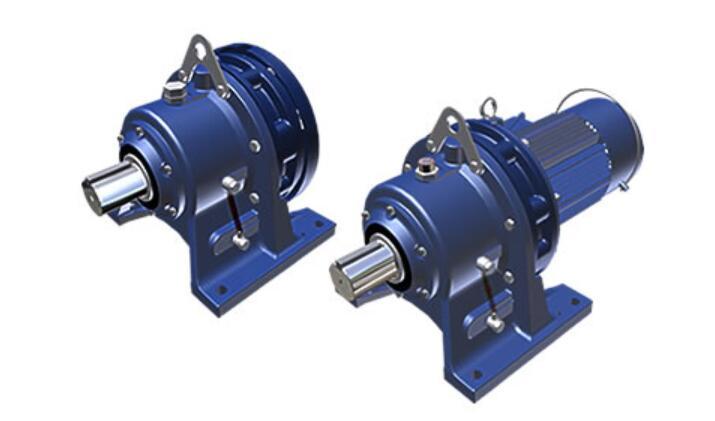

- Редуктор

Планетарный циклоидный редуктор - это новый тип редуктора с передовым дизайном и новой структурой, который использует принцип планетарной передачи и задействует циклоидное колесо. В большинстве случаев этот редуктор заменил двухступенчатые и трехступенчатые обычные цилиндрические редукторы и цилиндрические червячные редукторы, и широко используется в военной промышленности, аэрокосмической, металлургической, горнодобывающей, нефтяной, химической, корабельной, легкой, пищевой, текстильной, печатной и красильной, фармацевтической, резиновой, пластиковой, подъемной и транспортной.

Характеристики продукта:

- Высокое передаточное отношение.

- Высокая эффективность передачи.

- Компактная структура, небольшие размеры и малый вес.

- Меньше отказов, долгий срок службы.

- Плавная и надежная работа.

- Простая разборка и ремонт.

- Сильная перегрузочная способность, ударопрочность, малый момент инерции, подходит для частых запусков и работы в прямом и обратном направлениях.

Редуктор - это своеобразный механизм передачи мощности, который использует преобразователь скорости передачи для уменьшения числа оборотов двигателя до требуемого числа оборотов и получения конструкции с большим крутящим моментом.

Функция редуктора: Одновременное снижение скорости и увеличение крутящего момента на выходе. Коэффициент выходного крутящего момента умножается на коэффициент замедления двигателя, но он не должен превышать номинальный крутящий момент редуктора. В то же время, инерция локомотива уменьшается до квадрата коэффициента замедления.

- Подшипник скольжения

Подшипник поворота является силовым основным элементом машины, который требует относительного вращения между всеми двумя частями и несет осевую силу, радиальную силу и опрокидывающий момент в то же время. Его основная функция заключается в использовании болтов для крепления на верхних и нижних опорах механического оборудования для передачи силы и привода, чтобы реализовать относительное вращение между двумя частями механического оборудования. Она имеет характеристики компактной структуры, легкого веса, хорошей конструкционной стали, плавной работы, высокой точности, безопасности и надежности.

Подшипник поворота является основной частью механического оборудования и широко используется в различных отраслях народного хозяйства. Он широко используется в строительной технике, портовом оборудовании, металлургическом оборудовании, горном оборудовании, нефтяном оборудовании, химическом оборудовании, медицинском оборудовании, судовом оборудовании, оборудовании легкой промышленности, оборудовании для защиты окружающей среды, развлекательном оборудовании, транспортном оборудовании и военной технике. Качающиеся опоры все чаще используются в энергосберегающих и природоохранных проектах, таких как ветряные турбины, для которых требуются различные прецизионные комплекты опор для качающихся столбов.

- Шестерня

Шестерня - это механическая деталь в виде колеса, передающая крутящий момент за счет зацепления зубьев. Благодаря передаче крутящего момента с другими зубчатыми механическими деталями (такими как другая шестерня, рейка Дао и червяк), шестерня может изменять скорость и крутящий момент, менять направление движения и форму движения.

- Ось

Транспортировочная машина приводит во вращение внутреннюю передачу через вращение вала, а затем приводит во вращение внешнюю передачу, таким образом, достигая функции транспозиции

As a leading manufacturer in the field of welding automation, WUXI ABK MACHINERY, with years of technological accumulation, has developed the welding column boom and tank welding manipulator systems with excellent performance. Our automatic welding manipulator solution is widely used in the manufacturing fields of storage tanks, pressure vessels and heavy steel structures, providing efficient and reliable welding automation equipment for global customers.

In terms of core technologies, our welding manipulators manufacturers team has broken through many technical bottlenecks. The welding column boom adopts a high-strength box beam structure and undergoes precise stress relief treatment to ensure stability for long-term use. The tank welding manipulator system is equipped with high-precision guide rails and rack transmission mechanisms, and its operation stability can reach ±0.1mm/m, fully meeting the strict requirements of welding large storage tanks. The intelligent control system of automatic welding manipulator supports automatic weld seam tracking and real-time process monitoring, significantly improving the welding quality and efficiency.

For different application scenarios, we offer a full range of configuration options. Fixed welding manipulators are suitable for longitudinal seam welding of small and medium-sized storage tanks and have the characteristics of compact structure and economic efficiency. The fixed rotary configuration adds the column rotary function and is suitable for container welding that requires multi-angle operations. The mobile rotary tank welding manipulator is specially designed for on-site construction of large storage tanks and has the capabilities of omnidirectional movement and 360° rotation. All models can be synchronously linked with auxiliary equipment such as positioners and turntables.

In terms of security performance, our automatic welding manipulator system is equipped with multiple protection measures. The anti-fall self-locking device, in combination with multi-stage limit switches, ensures the safe operation of the equipment. The system also features all-round protection functions such as overload, overcurrent, undervoltage and short circuit. The user-friendly operation interface includes a visual control panel and a handheld remote control box, supporting precise adjustment of the welding torch posture, with a maximum adjustment range of up to 200mm.

We attach particular importance to the scalability of the product. The welding column boom system can be equipped with intelligent components such as flux recovery devices and real-time monitoring modules to meet the special process requirements of customers. As professional welding manipulators manufacturers, we provide full-process services from equipment selection to on-site commissioning to ensure that each tank welding manipulator can be perfectly adapted to the actual working conditions of customers.

At present, the automatic welding manipulator product of WUXI ABK has been successfully applied to more than 200 large-scale engineering projects, including key fields such as oil storage tanks, chemical containers and power generation equipment. All the equipment complies with the requirements of international standards such as ASME and EN 1090. We look forward to cooperating with you to jointly promote the development of welding automation technology. For more product information or to obtain customized solutions, please feel free to contact our technical team at any time.

Особенности сварочного манипулятора:

Структурное преимущество

V-образная конструкция направляющих шин-V-образные направляющие с высокой несущей способностью используются как для вертикальных стоек, так и для поперечных рычагов.

Двойная система безопасности

- Колонна оснащена тормозным двигателем для обеспечения стабильного позиционирования.

- Защита от излома предохранительного штифта направляющего сиденья + цепь предохранительных отверстий колонны

Прецизионная система передачи

- Циклоидальное пальцевое колесо+червячный редуктор

- Конструкция полностью герметичной системы смазки с погружением в масло и защитой от пыли

Интеллектуальное управление

- Преобразователь с плавным регулированием скорости (с функцией обнаружения неисправностей и сигнализации)

- Электрический регулятор поперечного рычага

- Поворотная опорная база обеспечивает синхронную сварку нескольких заготовок

Optional accessories

Flux recovery device/monitoring system/shelf, etc.

Industrial application

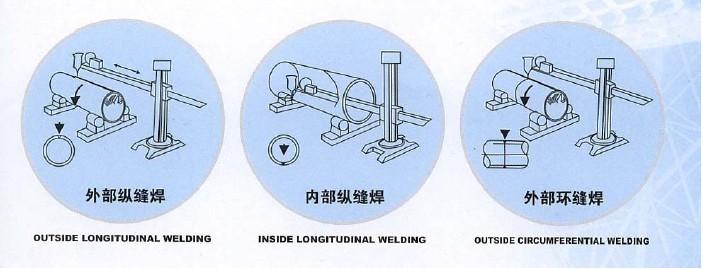

Boiler/pressure vessel/petrochemical/metallurgical fields, etc., suitable for longitudinal and circumferential seam welding inside and outside the cylinder.

Configuration options

Fixed/fixed rotary/moving rotary

Orking condition:

- a) Height above sea level: Below 1000m

- b) Ambient condition:-5℃~40℃

- c) Ambient Operating Conditions:Date average temperature≤25℃,Relative humidity in max humid month≤90%

- d) Voltage fluctuate:±10%(Frequency is rating value)

- e) Frequency fluctuate:≤±1%(Voltage is rating value)

Компания Wuxi ABK Machinery Co.Ltd является профессиональным производителем регулируемых сварочных вращателей в Китае. Кроме того, мы можем предоставить нашим клиентам по всему миру множество других продуктов, включая специальные сварочные вращатели, линии для производства ветряных башен, линии для сварки двутавровых балок, оборудование для сварки труб, отрезные станки с ЧПУ, шлифовальные станки, листогибочные станки, листогибочные машины и т.д. Мы получили сертификаты ISO и CE, а также предлагаем услуги OEM. Наша продукция была хорошо принята клиентами из многих стран, таких как Испания, Индия, Германия, Южная Африка, Бразилия, Чили, Аргентина, Россия, Италия, Франция, Вьетнам, и многое другое. Если вы заинтересованы в нашем регулируемом сварочном вращателе, пожалуйста, не стесняйтесь связаться с нами, когда захотите.