Ротатор 60T Fit Up

Ротатор WUXI ABK 60T Fit-Up Обеспечивает точное выравнивание ветряных башен и сосудов под давлением. Имеет самовыравнивающиеся ролики, грузоподъемность 60 тонн и регулировку скорости 0,3-3 об/мин. В комплект входят два двигателя мощностью 5,5 кВт и лазерное позиционирование (±0,5 мм). Сертифицирован по стандартам CE/ISO и имеет 18-месячную гарантию.

60 Tons Fit Up Rotator

CONVENTIONAL WELDING ROTATORS

FIT UP Series

Conventional Rotators are designed to aid in the welding of cylindrical vessels or columns.

| · Trusted design | · Reliable Quality |

| · Renowned parts | · Inverter control |

| · Direct drive system | · Motorised travel option |

| · Build to order custom design | · OEM

|

CONVENTIONAL WELDING ROTATORS

FIT UP Series

Conventional Rotators are designed to aid in the welding of cylindrical vessels or columns.

| · Trusted design | · Reliable Quality |

| · Renowned parts | · Inverter control |

| · Direct drive system | · Motorised travel option |

| · Build to order custom design | · OEM

|

- Summary

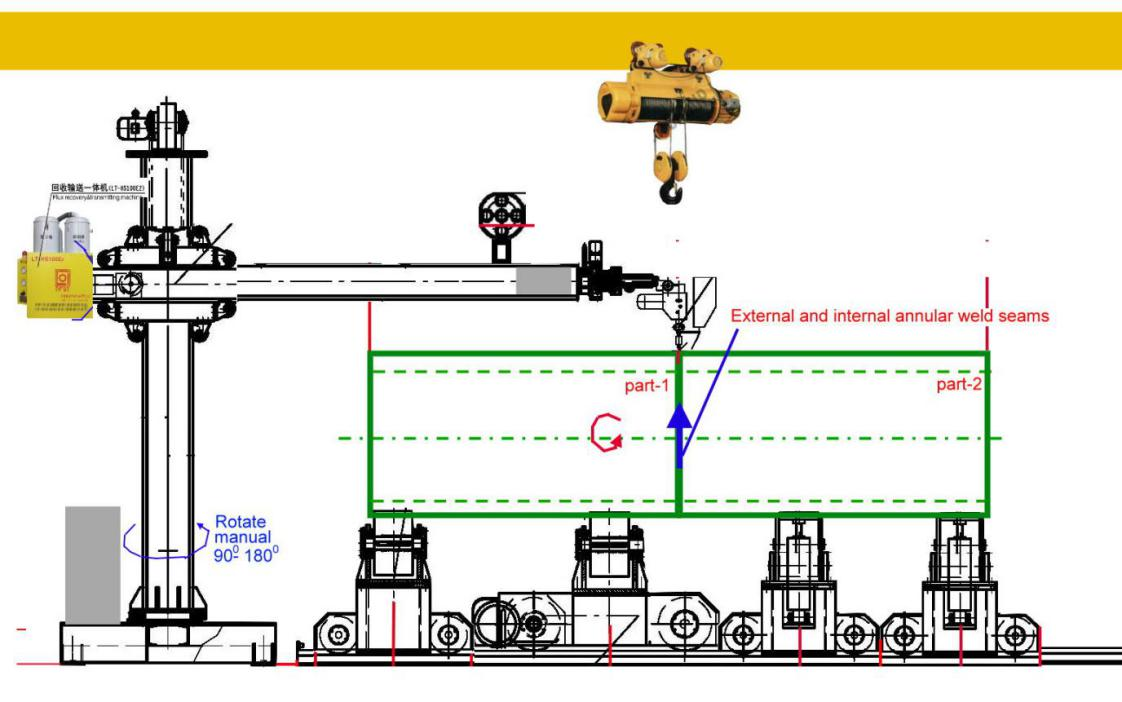

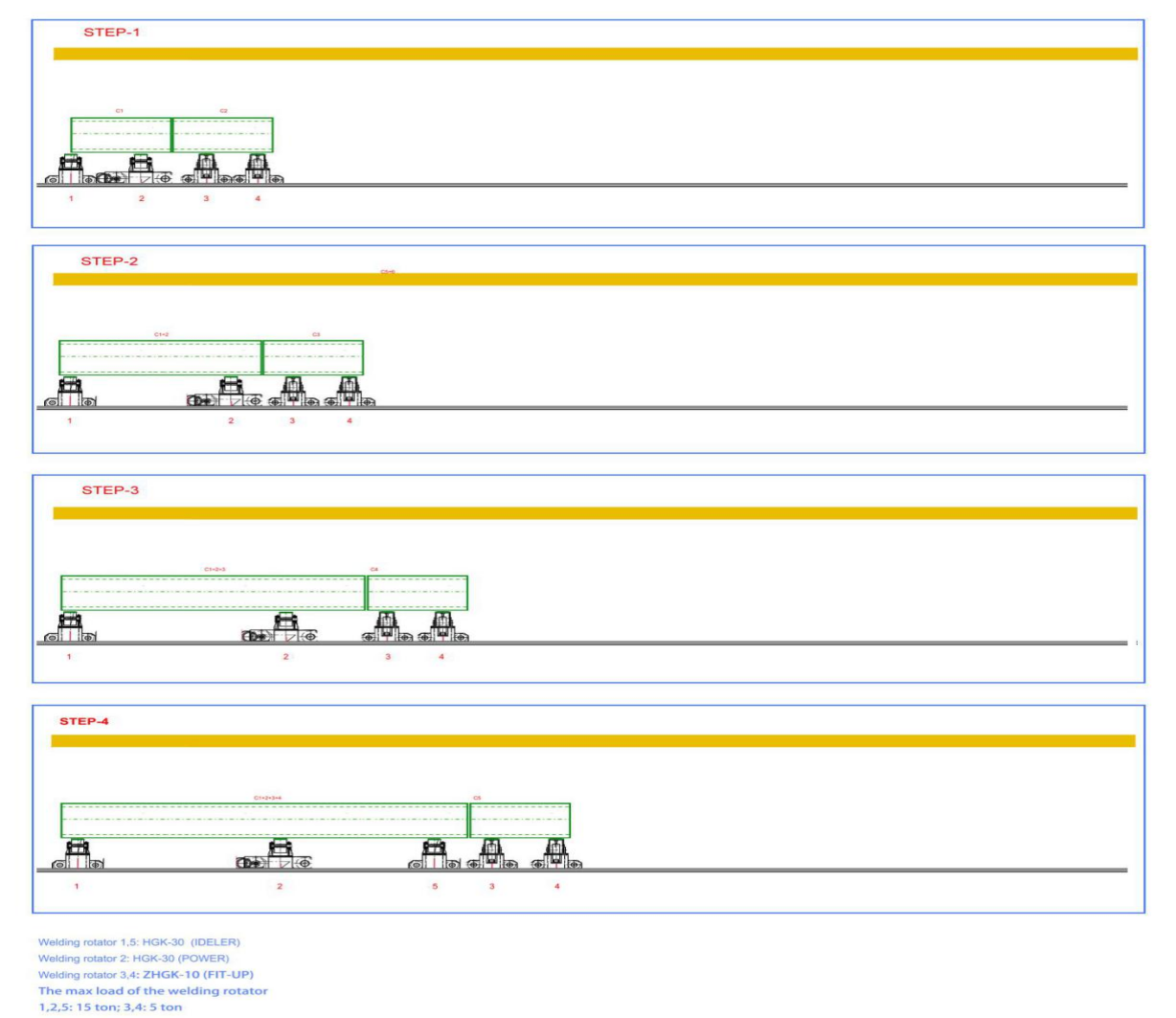

- Equipment composition

Сайт 60T Fit-Up Rotator is an advanced welding positioning system designed for изготовление сосудов под давлением, wind tower assembly, и large-diameter pipe welding. This industrial rotator combines precision alignment с heavy-duty performance, featuring a variable frequency drive system (0.1-1.2m/min adjustable speed) and hydraulic lifting technology (±0.5mm positioning accuracy).

Core Components

-

Driving roller frame: AC motor + reducer for smooth rotation

-

Driven roller frame: Ensures stability during welding operations

-

Hydraulic assembly roller frames (2 sets): Integrated lifting and track movement for precision fit-up

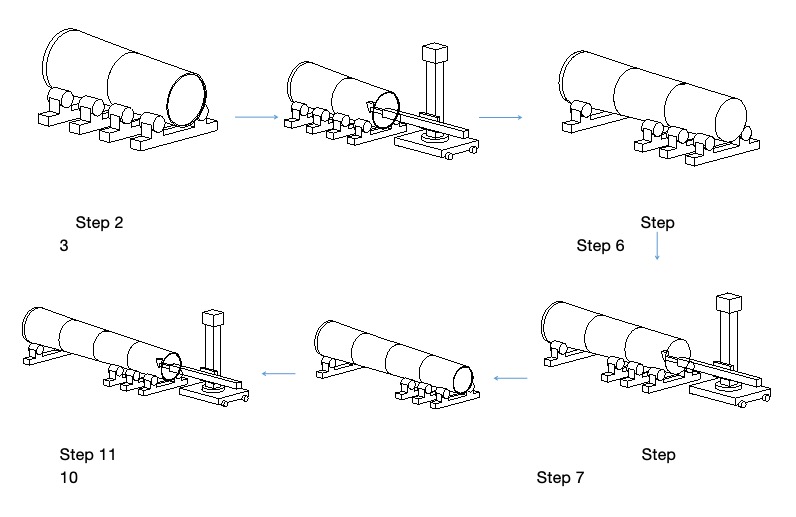

Workflow

-

Segmented Positioning: The first barrel is placed on the driving/driven frames, while the secondary barrel aligns via hydraulic adjustment.

-

Assembly & Welding: The сварочный манипулятор completes inner/outer seams after tack welding.

-

Continuous Expansion: The process repeats until the fabricated vessel is fully welded.

Technical Highlights

✓ 60-ton capacity (customizable for heavier loads)

✓ 1.5-6m diameter range для cylindrical workpieces

✓ Overload protection и anti-deflection system for safety

✓ Emergency braking ensures operator protection

Applications

-

Pressure vessel manufacturing

-

Wind tower segment welding

-

Pipeline girth welding

-

Storage tank construction

Почему стоит выбрать WUXI ABK?

-

20+ years in автоматизация сварки

-

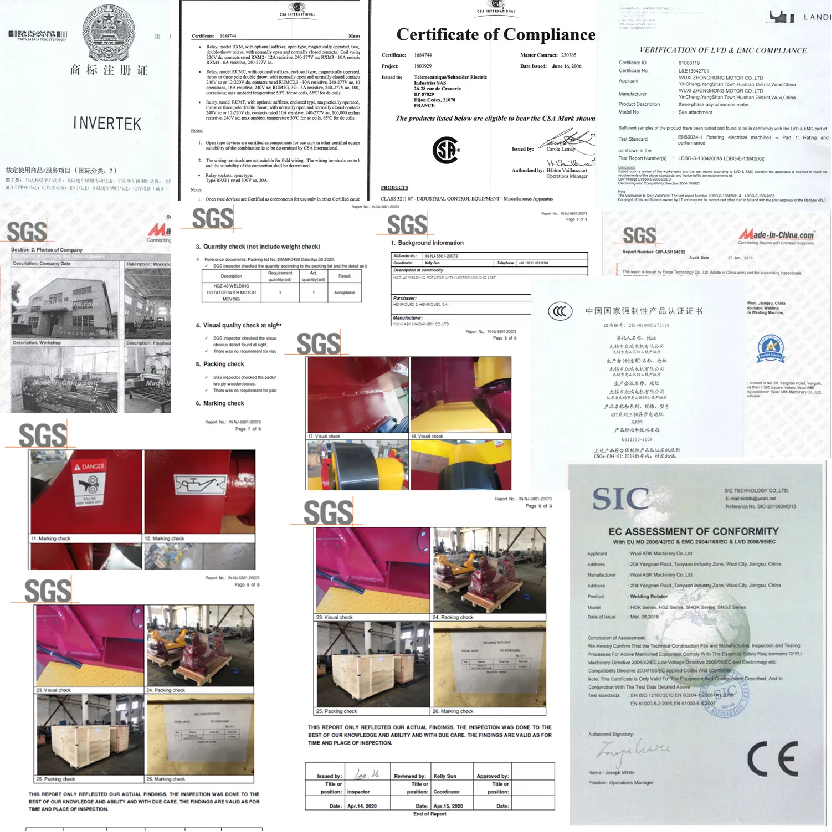

CE/ISO сертифицирован for quality assurance

-

24/7 technical support

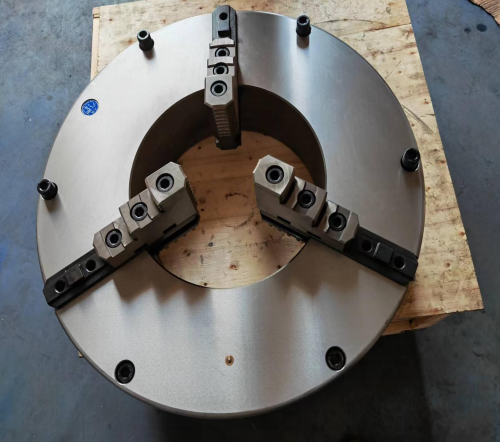

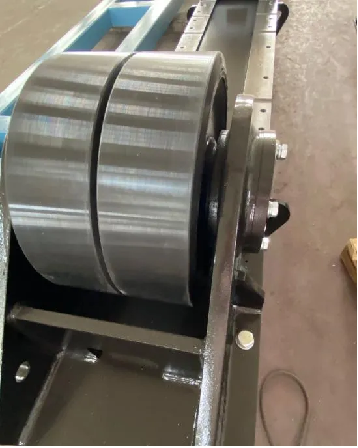

Wheel introduction

Polyurethane wheels offer exceptional abrasion resistance, versatile processing, wide applicability, and superior resistance to oil, ozone, aging, radiation, and low temperatures. They also provide strong adhesion, excellent sound transmission, biocompatibility, and blood compatibility.

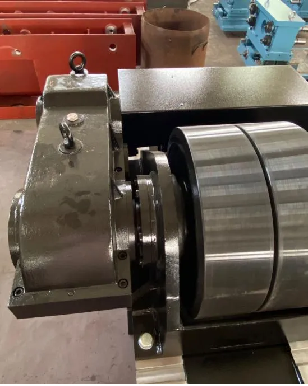

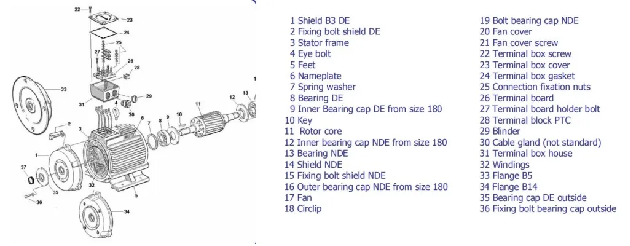

Motor introduction

Product Overview

The WUXI ABK 60T Fit-Up Rotator is engineered for precision alignment and rotation of heavy cylindrical components in wind tower fabrication, pressure vessel manufacturing, and shipbuilding applications. With a 60-ton load capacity and self-aligning roller system, this industrial-grade rotator ensures stable workpiece rotation (±0.2° accuracy) for optimal weld quality.

Maintenance Protocol

-

Pre-Operation

-

Clean all rotator surfaces, especially rubber rollers (keep oil-free and below 60°C)

-

Assign certified personnel for operation and maintenance

-

-

Lubrication

-

Fill speed reducer with 30# engine oil (ISO VG 150)

-

Use low-temperature synthetic oil when ambient <0°C

-

First oil change at 30 days, then every 500 operating hours

-

-

Critical Safeguards

-

Never use roller bed as welding ground – employ separate grounding clamps

-

Monthly inspection of tapered roller bearings и gear reducers

-

Technical Advantages

-

Self-aligning roller system adapts to 5-80mm workpiece eccentricity

-

Dual-motor drive (2×5.5kW) with 0.3-3 RPM stepless control

-

Modular design for quick field assembly/disassembly

-

Laser-guided alignment (±0.5mm) for wind tower sections

Quality Assurance

As a leading rotator manufacturer with 20+ years expertise, WUXI ABK provides:

✓ CE/ISO 9001 certified manufacturing

✓ 18-month warranty on drive systems

✓ Free replacement of wearing parts (rollers, gears)

✓ 24/7 technical support for wind energy projects

Компания Wuxi ABK Machinery Co.Ltd является профессиональным производителем сварочных вращателей в Китае. И наш сварочный вращатель в основном включает в себя стандартный сварочный вращатель, регулируемый сварочный вращатель и специальный сварочный вращатель. Мы также можем предоставить нашим клиентам по всему миру множество других продуктов, включая сварочный поворотный стол, сварочный аппарат для свай, линию для производства ветряных башен, линию для сварки двутавровых балок, оборудование для сварки труб, отрезной станок с ЧПУ, шлифовальный станок, роликовый формовочный станок, листогибочный станок и т.д. Мы получили сертификаты ISO и CE, а также предлагаем услуги OEM.