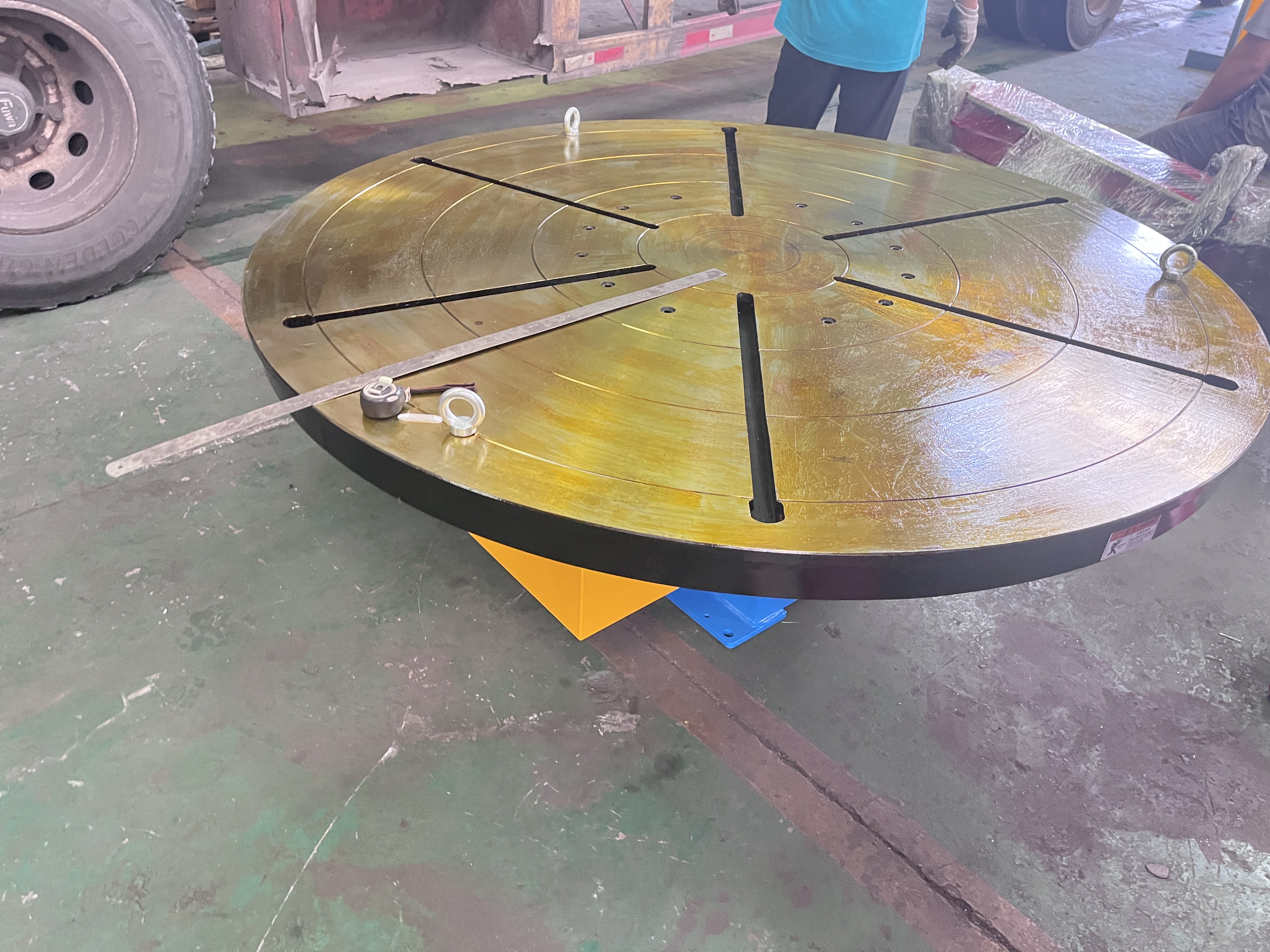

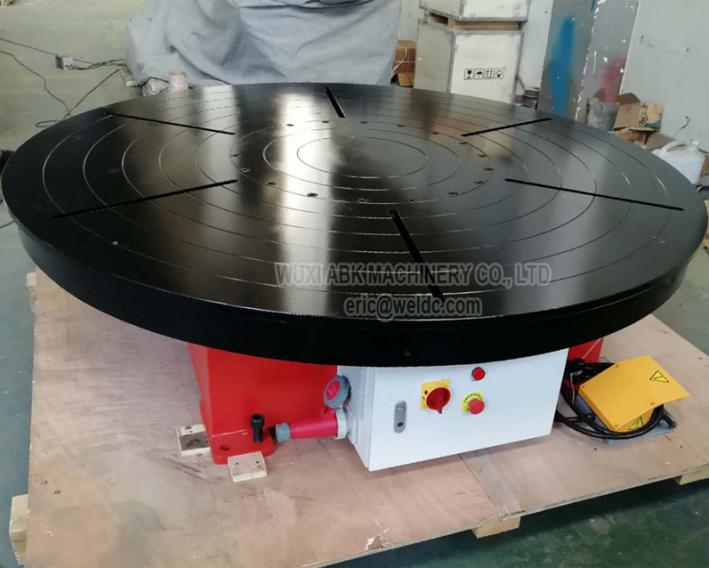

Сварочный поворотный стол 20 тонн

Сварочный поворотный стол WUXI ABK 20 тонн Обеспечивает точное вращение при изготовлении изделий средней сложности. Благодаря прочной стальной раме и регулировке скорости 0,5-5 об/мин он позволяет обрабатывать сосуды под давлением, конструкционную сталь и детали машин. Благодаря точности ±0,2 мм и защите IP54 этот поворотный стол, сертифицированный CE, обеспечивает надежную работу в промышленных условиях.

WUXI ABK Welding Equipment: Precision Rotation Solutions

Technical Advantages

✔ Programmable Rotation – Digital control maintains 0.1-1.2 RPM for various joining requirements

✔ Load Optimized – Standard 1-50 ton capacity with custom configurations available

✔ Adaptable Surface – Modular worktable accepts 800-6000mm diameter assemblies

✔ Precision Movement – ±0.5mm repeatability ensures joint accuracy

Industrial Implementation

The welding turntable serves critical functions in:

- Cylindrical pressure container fabrication

- Energy sector component manufacturing

- Heavy steel structure production

- Marine construction applications

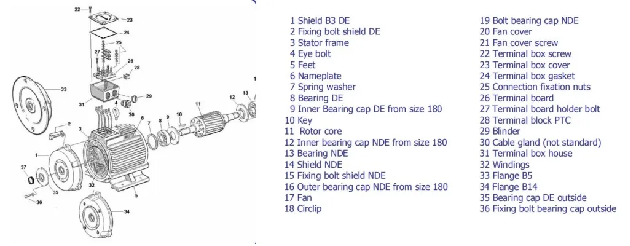

Mechanical Composition

- Reinforced support base with industrial-grade bearings

- Variable frequency drive system

- Interchangeable mounting surfaces

- Safety-rated enclosure options

Custom Engineering Services

WUXI ABK provides:

- Specialized surface treatments

- Automated position feedback systems

- Integrated quality monitoring

- Operator interface customization

Manufacturing Excellence

Our rotation systems feature:

- ISO-certified production processes

- Performance validation testing

- Extended service coverage

- Global technical support network

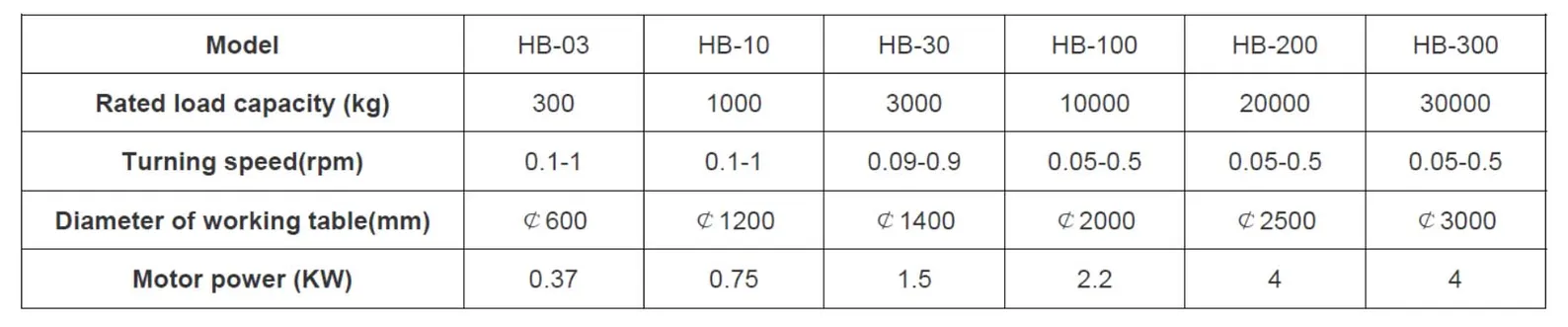

| Модель | HB-200 | ||

| Грузоподъемность | (KG) | 20000 | |

| Скорость вращения | (RPM) | 0.05-0.5 | |

| Размер рабочего стола Диаметр | (MM) | 2000 | |

| Power | (KW) | 4 | |

| Источник питания | (V) | 50 Гц 3ɸ | 380 |

| Тип регулировки скорости | Плавное регулирование частоты переменного тока | ||

| Примечание: Все технические характеристики относятся к стандартному оборудованию, которое может быть изменено в соответствии с требованиями заказчика. | |||

Сайт Сварочный поворотный стол WUXI ABK 20 тонн is a precision rotating platform designed for medium to heavy workpiece welding, including pipes, flanges, and structural components. На сайте 360° smooth rotation с adjustable speed (1-10 RPM)это industrial-grade turntable ensures consistent weld seam quality while reducing labor time by 50% compared to manual methods. Built for durability and stability, it supports up to 20 tons с vibration-free operation.

Technology Funcation

| · Trusted design | · Reliable Quality |

| · Renowned parts | · Inverter control |

| · Direct drive system | · Motorised travel option |

| · Build to order custom design | · OEM |

Parameter list of conventional Welding Turntable

Key Features:

-

Heavy-duty steel construction с 6 high-rigidity support ribs (deformation resistance <0.08mm/m²)

-

Precision worm gear transmission (ISO 5 grade, zero-backlash, 10,000+ hour service life)

-

Multi-position T-slot worktable (6 slots, 14mm width, 5000N clamping force per slot)

-

Intelligent control system (touchscreen HMI, automatic lubrication, IP54 protection)

-

Stabilized base (200mm steel plate, 8-point leveling, <0.01mm vibration absorption)

Performance Advantages:

✓ 40% faster setup с one-touch operation

✓ 60% reduction in workpiece deformation due to military-grade welding seams

✓ 30% более длительный срок службы compared to standard turntables

Applications:

✔ Pipe and flange welding

✔ Structural steel fabrication

✔ Pressure vessel assembly

✔ Heavy machinery component production

1. Подшипник поворота

Slewing bearing is the force basic element of machine, which requires relative rotation between all two parts and bears axial force, radial force and overturning moment at the same time.Its basic function is to use bolts to fix it on the upper and lower supports of mechanical equipment to transmit force and drive so as to realize the relative rotation between the two parts of mechanical equipment.Rotary support generally has installation holes, internal or external gears, lubrication holes and sealing devices. It has the characteristics of compact structure, light weight, good structural steel, smooth operation, high accuracy, safety and reliability.

Slewing bearing is a basic part of mechanical equipment and widely used in various industries of national economy. It is widely used in construction machinery, port machinery, metallurgical machinery, mining machinery, petroleum machinery, chemical machinery, medical equipment, ship machinery, light industrial machinery, environmental protection machinery, entertainment equipment, transportation machinery equipment.Swing supports are increasingly used in energy-saving and environmental protection projects, such as wind turbines that require a variety of precision pole swing support kits.

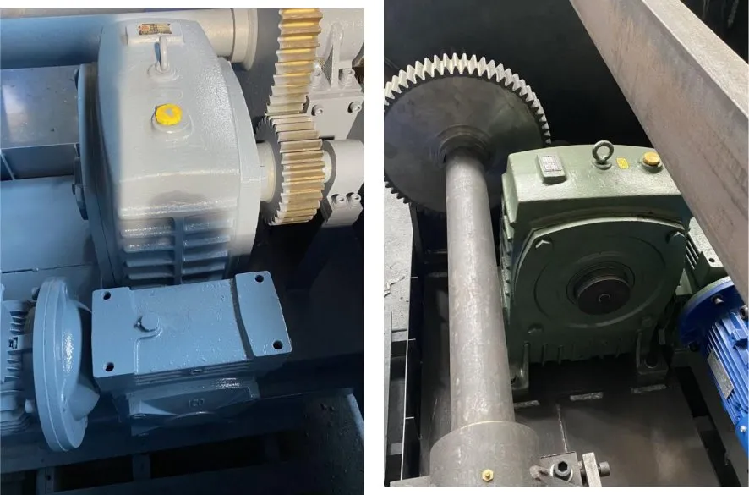

- Шестерня

Gear is a wheel like mechanical part which transmits the torque by the engagement of teeth. Through the transmission with other toothed mechanical parts (such as another gear, Dao rack and worm), the gear can change the speed and torque, change the direction of motion and change the form of motion.

3.Редуктор

The reducer is a kind of power transmission mechanism, which uses the speed converter of gear to reduce the rotation number of motor to the required rotation number and obtain a structure with large torque.

Function of reducer:Reduce the speed and increase the output torque at the same time. The torque output ratio is multiplied by the motor output deceleration ratio, but it shall not exceed the rated torque of the reducer.At the same time, the inertia of the lo.ad is reduced to the square of the deceleration ratio.

4. Motor

Welding Turntable Maintenance Guidelines

Core maintenance content

Daily maintenance-cleaning welding slag, checking lubrication and electrical safety.

Regular maintenance-tighten bolts, check transmission mechanism and test safety function.

Deep maintenance-annual replacement of worn parts, re-lubrication and system calibration

Fault early warning-Stop immediately when abnormal noise/uneven rotation occurs.

Maintain value

- Extend the service life of equipment by more than 30%

- Reduce sudden downtime

- Ensure the stability of welding accuracy.

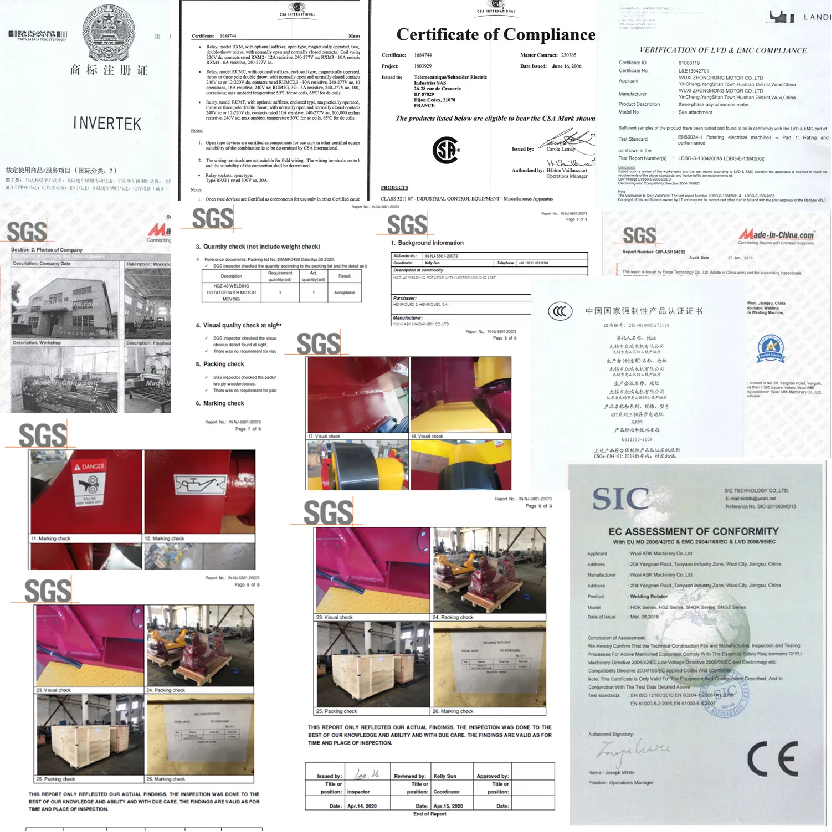

Сертификация продукции

Step into the future of welding technology with our cutting-edge solutions.

From automated processes to intuitive controls, our products are at the forefront of innovation, providing you with the tools you need to stay ahead in today’s competitive market!

Компания Wuxi ABK Machinery Co.Ltd является профессиональным производителем сварочных вращателей в Китае. И наш сварочный вращатель в основном включает в себя стандартный сварочный вращатель, регулируемый сварочный вращатель и специальный сварочный вращатель. Мы также можем предоставить нашим клиентам по всему миру множество других продуктов, включая сварочный поворотный стол, сварочный аппарат для свай, линию для производства ветряных башен, линию для сварки двутавровых балок, оборудование для сварки труб, отрезной станок с ЧПУ, шлифовальный станок, роликовый формовочный станок, листогибочный станок и т.д. Мы получили сертификаты ISO и CE, а также предлагаем услуги OEM.