3 Axis Precision Positioner 1 Ton

Сварочный позиционер WUXI ABK 1-Ton 3-Axis Обеспечивает точное позиционирование для роботизированных сварочных работ. Благодаря функциям наклона/поворота с сервоприводом (наклон 0-135°, повторяемость ±0,5°) этот позиционер, сертифицированный CE, подходит для автомобильной оснастки и аэрокосмических компонентов. Благодаря совместимым с FANUC элементам управления и защите IP54 он обеспечивает 50 000+ циклов без технического обслуживания.

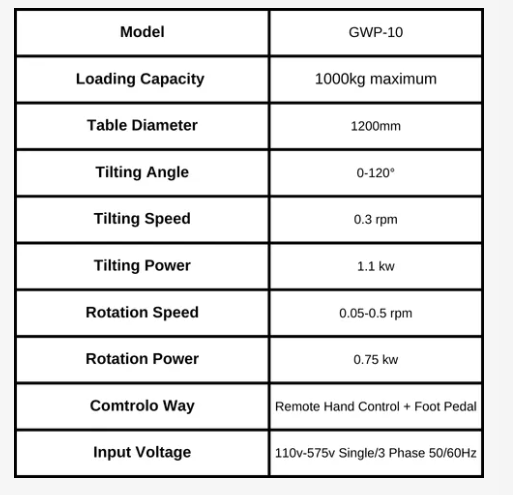

1 Tons 3 Axis Positioner Parameter Table

Precision Multi-Axis Control

The WUXI ABK 1-Ton 3-Axis Positioner delivers exceptional maneuverability for complex welding applications, featuring fully synchronized turning (180°), rotating (360° continuous), and tilting (0-90°) movements. With ±0.05mm positioning accuracy и 0.02mm repeatabilityэто industrial-grade positioner ensures weld seam consistency for роботизированные сварочные камеры и precision fabrication.

Heavy-Duty Structural Design

-

5-ton dynamic load capacity supported by a rigid integral casting base

-

Premium motion components: Japan THK linear guides + Germany SEW reducers

-

Vibration-damped construction maintains stability during high-deposition welding

Intelligent Operation & Safety

Сайт 3-axis welding positioner incorporates:

✓ Overload auto-shutdown protection

✓ <0.1s emergency braking system

✓ IP54-rated control cabinet for harsh environments

Universal Compatibility

Designed for automated welding systems, it features:

-

ABB/KUKA/FANUC robot interfaces

-

PLC + touchscreen dual control

-

Pre-programmed welding position memory

Technical Specifications

| Parameter | Specification |

|---|---|

| Max Load | 1 ton (5-ton dynamic capacity) |

| Tilt Range | 0-90° (±0.05°) |

| Rotation | 360° continuous |

| Control | Siemens PLC + 10″ HMI |

| Power | 380V/50Hz (IP54) |

Applications

• Automotive component welding

• Aerospace structural fabrication

• Heavy equipment repair

• Pressure vessel circumferential seams

1.Slewing bearing

Slewing bearing is the force basic element of machine, which requires relative rotation between all two parts and bears axial force, radial force and overturning moment at the same time.Its basic function is to use bolts to fix it on the upper and lower supports of mechanical equipment to transmit force and drive so as to realize the relative rotation between the two parts of mechanical equipment.Rotary support generally has installation holes, internal or external gears, lubrication holes and sealing devices. It has the characteristics of compact structure, light weight, good structural steel, smooth operation, high accuracy, safety and reliability.

Slewing bearing is a basic part of mechanical equipment and widely used in various industries of national economy. It is widely used in construction machinery, port machinery, metallurgical machinery, mining machinery, petroleum machinery, chemical machinery, medical equipment, ship machinery, light industrial machinery, environmental protection machinery, entertainment equipment, transportation machinery equipment.Swing supports are increasingly used in energy-saving and environmental protection projects, such as wind turbines that require a variety of precision pole swing support kits.

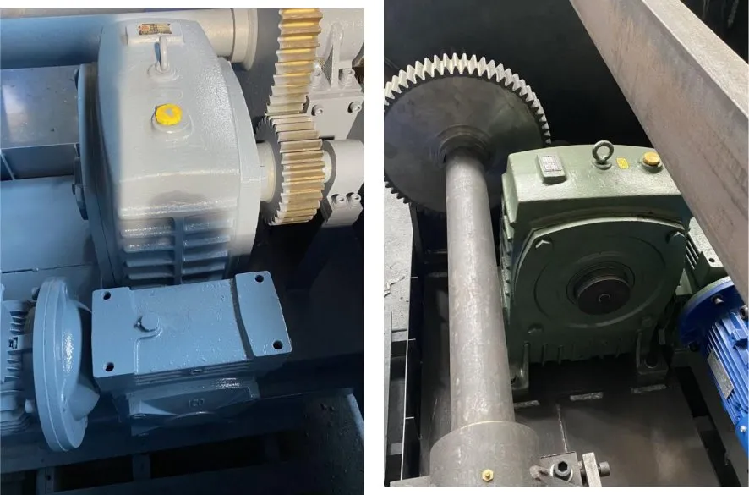

2.Gear

Gear is a wheel like mechanical part which transmits the torque by the engagement of teeth. Through the transmission with other toothed mechanical parts (such as another gear, Dao rack and worm), the gear can change the speed and torque, change the direction of motion and change the form of motion.

3.Редуктор

The reducer is a kind of power transmission mechanism, which uses the speed converter of gear to reduce the rotation number of motor to the required rotation number and obtain a structure with large torque.

Function of reducer:Reduce the speed and increase the output torque at the same time. The torque output ratio is multiplied by the motor output deceleration ratio, but it shall not exceed the rated torque of the reducer.At the same time, the inertia of the lo.ad is reduced to the square of the deceleration ratio.

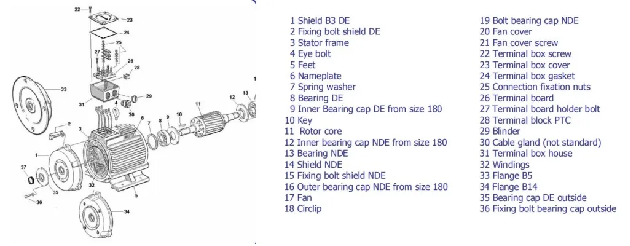

4.Motor

Comprehensive Maintenance Protocol

Proper maintenance ensures optimal performance of your 1-ton 3-axis welding positioner для роботизированные сварочные камеры и precision fabrication. Daily care includes removing сварочный шлак deposits, verifying lubrication levels in the harmonic drive system, and inspecting electrical connections. Monthly procedures involve torque-checking servo motor mounts, testing the tilting mechanism (0-135° range), and calibrating the PLC-controlled positioning (±0.5° repeatability). Annual deep maintenance requires replacing wear-resistant nylon gears, replenishing EP2-grade grease in all axis reducers, and laser-aligning the rotary table surface.

Critical Maintenance Benefits

-

Extends service life by 30%+ through precision component care

-

Prevents unplanned downtime in automated production lines

-

Maintains ±0.1mm welding accuracy для aerospace-grade joints

-

Preserves IP54-rated protection against spatter and dust

Fault Prevention Measures

Immediately halt operation if detecting:

✓ Abnormal vibration in 3-axis drive motors

✓ Irregular motion during positioner tilting

✓ Fluctuations in servo current draw

Certifications & Technological Edge

Наш сайт CE/ISO-certified positioners integrate:

-

Robotic interface (FANUC/Motoman compatibility)

-

Smart load detection (1-ton dynamic capacity)

-

Real-time tilt monitoring для complex weldments

Компания Wuxi ABK Machinery Co.Ltd является профессиональным производителем сварочных вращателей в Китае. И наш сварочный вращатель в основном включает в себя стандартный сварочный вращатель, регулируемый сварочный вращатель и специальный сварочный вращатель. Мы также можем предоставить нашим клиентам по всему миру множество других продуктов, включая сварочный поворотный стол, сварочный аппарат для свай, линию для производства ветряных башен, линию для сварки двутавровых балок, оборудование для сварки труб, отрезной станок с ЧПУ, шлифовальный станок, роликовый формовочный станок, листогибочный станок и т.д. Мы получили сертификаты ISO и CE, а также предлагаем услуги OEM.