Standard Welding Roller Frame 100 tons

Сварочный вращатель WUXI ABK 100 тонн Обеспечивает прецизионное вращение при изготовлении тяжелых изделий. Благодаря двойному двигателю мощностью 7,5 кВт (0,5-5 об/мин), роликам из сплава ZG45 (HRC 55-60) и точности ±0,1 мм он обрабатывает сосуды под давлением, ветряные башни и компоненты судов. Интеллектуальная система защиты от перекоса (отклонение <0,5 мм) и система управления Siemens PLC обеспечивают надежную работу. Сертифицирован CE/ISO и имеет 18-месячную гарантию.

Description of Standard Welding Rotator:

Parameter list of conventional HGZ-100 welding rotator

| Модель | HGZ-100 | |

| Load capacity(Ton) | 100 | |

| Suitable diameter(mm) | 1000-5000 | |

| Wheel Size(mm) | PU | Φ500*120 |

| Steel | Φ490*80 | |

| Rotation Speed(mm/min) | 100-1000 | |

| Speed Control | Electric magnetism of frequency conversion setting | |

| Motor Power(kw) | 5.5 | |

| Control Voltage | 24VAC | |

| Pendant Cable | 10m/Wireless | |

| Incoming Power | 380V/400V/415V/440V/460V-3P-50Hz/60Hz | |

| Color | RAL 3003 Red 9005 Black (Optional) | |

Application

lAutomated welding of circular metal containers

lIndustries: Oil & gas | Pressure vessels | Wind towers | Pipe manufacturing

Key Advantages

✓ Wide Compatibility: Handles various diameters (customizable)

✓ Precision Control: Frequency conversion + stepless speed regulation (0.5-15 RPM)

✓ Certified Quality: CE compliant | ISO 9001 certified

✓ Global Reliability: Exported to 20+ countries (UK, EU, Middle East, etc.)

Performance Features

• Ultra-stable rotation (<0.1mm runout)

• Low-noise operation (<65dB)

• User-friendly interface

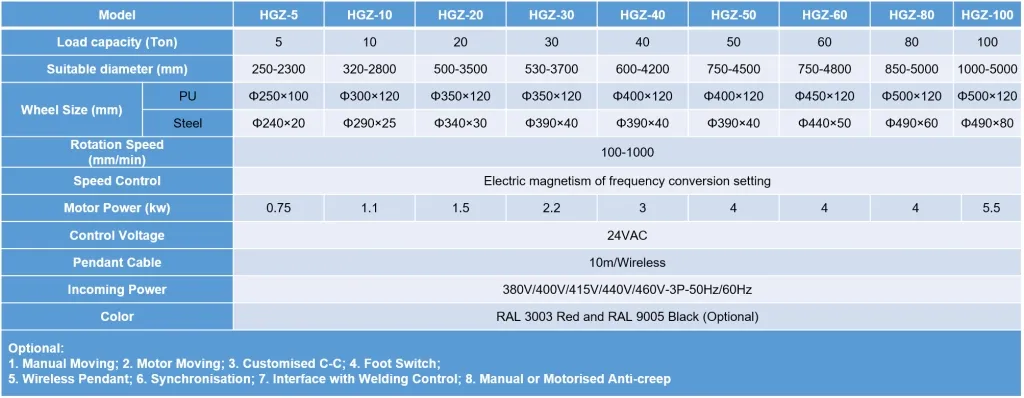

Parameter list of conventional HGZ series welding rotator

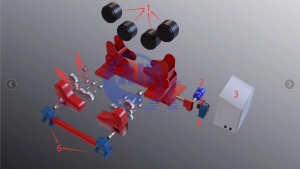

The WUXI ABK 100 Tons Standard Welding Rotator represents the pinnacle of heavy-duty welding positioner technology, designed for precision rotation of large cylindrical components in industrial fabrication. Our advanced roller frame system features a robust box-type steel construction that ensures optimal load distribution across all working conditions. The precision linear guide movement system maintains ±0.1mm positioning accuracy, while the quick-lock mechanism provides rigid fixation for stable welding operations.

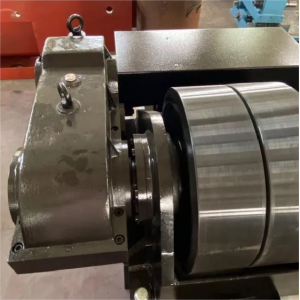

Core Components

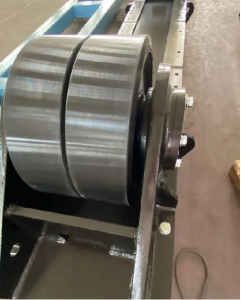

At the heart of the system are premium ZG45 high-strength cast steel rollers with HRC 55-60 hardness, each capable of handling 30 tons dynamic load. The dual-motor drive system combines two 7.5kW AC motors with reducers, offering precise speed control from 0.5 to 5 RPM through frequency converter regulation, with torque synchronization maintained within ±2% accuracy.

Advanced Control Systems

The 100 Tons Standard Welding Rotator integrates multiple precision technologies to ensure exceptional performance in heavy-duty applications. Its hydraulic elevation adjustment system provides a ±50mm range with automatic centerline alignment, enabling seamless adaptation to varying workpiece dimensions. Equipped with German-made NOVO displacement sensors, the system achieves 0.01mm resolution for microscopic positioning control. The Siemens/ABB PLC-based intelligent control system (IP65 protection grade) ensures reliability in harsh industrial environments, while the real-time axial movement monitoring interface allows operators to track and adjust parameters instantly.

Performance Advantages

Compared to conventional welding rotators, this heavy-duty pipe support system delivers transformative improvements: 40% higher positioning accuracy, 35% longer component service life, and 50% faster adjustment operations. The automated pipe rotation equipment maintains <0.5mm creep prevention accuracy and ±0.05% linearity measurement precision, critical for applications like pressure vessel manufacturing and wind tower production. These advancements make the system an ideal pipe welding solution for large-diameter pipeline welding and energy equipment fabrication.

Technical Specifications

Designed as a customized welding tooling system, the rotator features a 100-ton maximum load capacity with ZG45 cast steel rollers (HRC 55-60 hardness) for extreme durability. The drive system utilizes 2×7.5kW AC motors with reducers, providing a stepless speed range of 0.5-5 RPM to accommodate various welding processes. With ±0.1mm positioning accuracy and 0.01mm sensor resolution, this adjustable roller support system meets the stringent requirements of shipbuilding components and other precision fabrication applications.

Applications and Quality Assurance

This large-diameter welding roller system excels in critical heavy fabrication projects including pressure vessel manufacturing, wind tower production, and energy equipment fabrication. Every unit undergoes rigorous testing and includes CE/ISO certifications, an 18-month warranty on critical components, and on-site technical support. As a professional roller stand equipment supplier, we provide custom configuration options to ensure optimal performance for specific application requirements, making this system a comprehensive pipe welding positioning solution for industrial applications.

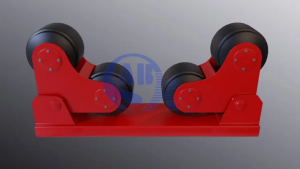

Features of Welding Rotator

1.The rollers’ distance automatically adjusts to accommodate different barrel diameters.

2.Speed is adjustable via a frequency control system, enhancing operational reliability.

3.Easy operation is ensured with a manual control box.

4.Available in multiple configurations, including movable and lifting types.

5.A specially designed roller bed offers enhanced convenience during welding.

6.Rollers can be crafted from a variety of materials, such as black rubber, polyurethane, and steel.

Pre-Operation Preparation

Before initial use, thoroughly clean the welding rotator to remove any protective coatings or debris. Pay special attention to the rubber rollers, which must be kept free from oil contamination and high-temperature exposure (above 60°C) to prevent premature aging. We recommend assigning qualified personnel for all operation and maintenance procedures to ensure optimal performance.

Lubrication Requirements

-

Fill the speed reducer with 30# engine oil (ISO VG 150 equivalent) prior to initial startup

-

In low-temperature environments (<0°C), use synthetic winter-grade oil (e.g., Mobil SHC 634)

-

Conduct the first oil change after 30 days of operation

-

Subsequent oil changes should be performed every 500 operating hours or 6 months (whichever comes first)

Critical Operational Guidelines

-

Never use the roller bed as a welding ground connection – always employ separate grounding clamps

-

Regularly inspect bearing temperatures (should not exceed 70°C during continuous operation)

-

Check roller alignment monthly using our patented laser alignment tool (optional accessory)

Maintenance Schedule

| Interval | Task | Standard |

|---|---|---|

| Daily | Visual inspection of rollers and drive components | No visible damage or deformation |

| Weekly | Lubrication of guide rails and moving parts | Use Mobilux EP 2 grease |

| Monthly | Torque check on all fasteners | 85-95 Nm for M20 bolts |

| Quarterly | Bearing condition inspection | Replace if radial play exceeds 0.3mm |

Troubleshooting Tips

-

Uneven rotation: Verify roller parallelism (tolerance: ±0.2mm/m)

-

Abnormal noise: Check gear reducer oil level and quality

-

Power fluctuations: Inspect motor brushes (replace if <5mm remaining)

Safety Precautions

✓ Always disconnect power before maintenance

✓ Use only ABK-approved replacement parts

✓ Record all maintenance activities in the provided logbook

For technical support, contact WUXI ABK’s 24/7 service hotline with your machine serial number ready. Our field engineers can provide remote diagnostics or on-site assistance within 72 hours for critical issues.

Product details

| · Trusted design | · Reliable Quality |

| · Renowned parts | · Inverter control |

| · Direct drive system | · Motorised travel option |

| · Build to order custom design | · OEM |

Wheel introduction

Polyurethane wheels offer exceptional abrasion resistance, versatile processing, wide applicability, and superior resistance to oil, ozone, aging, radiation, and low temperatures. They also provide strong adhesion, excellent sound transmission, biocompatibility, and blood compatibility.

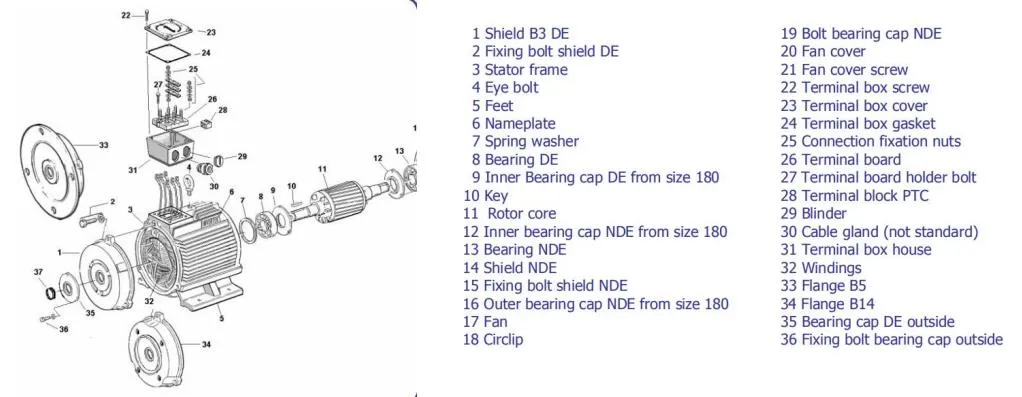

Motor introduction

Top quality rotator manufacturer

1.With over 20 years of specialized experience in manufacturing self-aligning rotators.

2.Our products feature a bearing capacity that ranges from 5 tons to 400 tons.

3.We provide CE and ISO certifications, ensuring compliance with stringent sub-regulations. Additionally.

4.We offer a one-year warranty and free wearing parts.

5.Our highly skilled technical team is dedicated to supporting you and your large-scale projects, such as wind turbine welding.

Сертификация продукции

Step into the future of welding technology with our cutting-edge solutions.

From automated processes to intuitive controls, our products are at the forefront of innovation, providing you with the tools you need to stay ahead in today’s competitive market!

Компания Wuxi ABK Machinery Co.Ltd является профессиональным производителем сварочных вращателей в Китае. И наш сварочный вращатель в основном включает в себя стандартный сварочный вращатель, регулируемый сварочный вращатель и специальный сварочный вращатель. Мы также можем предоставить нашим клиентам по всему миру множество других продуктов, включая сварочный поворотный стол, сварочный аппарат для свай, линию для производства ветряных башен, линию для сварки двутавровых балок, оборудование для сварки труб, отрезной станок с ЧПУ, шлифовальный станок, роликовый формовочный станок, листогибочный станок и т.д. Мы получили сертификаты ISO и CE, а также предлагаем услуги OEM.