Standard Duty Welding Rotator 80 Tons

Сварочный вращатель WUXI ABK 80 тонн Обеспечивает прецизионное вращение для тяжелых промышленных применений. Благодаря двойному двигателю мощностью 7,5 кВт (0,5-5 об/мин) и роликам из сплава ZG45 (HRC 55-60) он обеспечивает точность ±0,1 мм при обработке сосудов под давлением, ветряных башен и компонентов судов. Интеллектуальная система защиты от ползучести (отклонение <0,5 мм) и управление с помощью ПЛК Siemens гарантируют надежную работу. Сертифицирован CE/ISO и имеет 18-месячную гарантию. Идеально подходит для сложных производств, требующих 80-тонной грузоподъемности.

Description of Standard Welding Rotator:

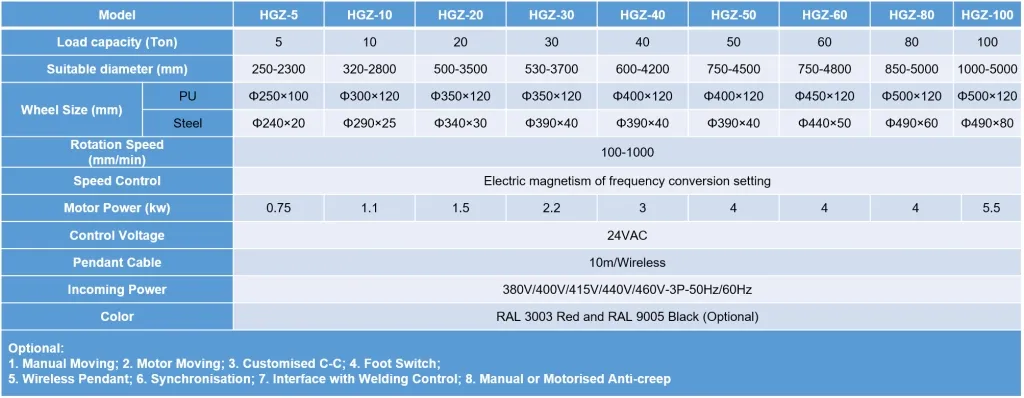

Parameter list of conventional HGZ-80 welding rotator

| Модель | HGZ-80 | |

| Load capacity(Ton) | 80 | |

| Suitable diameter(mm) | 850-5000 | |

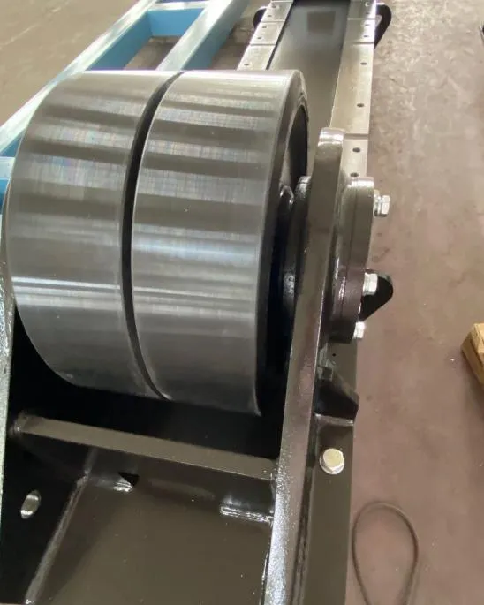

| Wheel Size(mm) | PU | Φ500*120 |

| Steel | Φ490*60 | |

| Rotation Speed(mm/min) | 100-1000 | |

| Speed Control | Electric magnetism of frequency conversion setting | |

| Motor Power(kw) | 4 | |

| Control Voltage | 24VAC | |

| Pendant Cable | 10m/Wireless | |

| Incoming Power | 380V/400V/415V/440V/460V-3P-50Hz/60Hz | |

| Color | RAL 3003 Red 9005 Black (Optional) | |

Application

lAutomated welding of circular metal containers

lIndustries: Oil & gas | Pressure vessels | Wind towers | Pipe manufacturing

Key Advantages

✓ Wide Compatibility: Handles various diameters (customizable)

✓ Precision Control: Frequency conversion + stepless speed regulation (0.5-15 RPM)

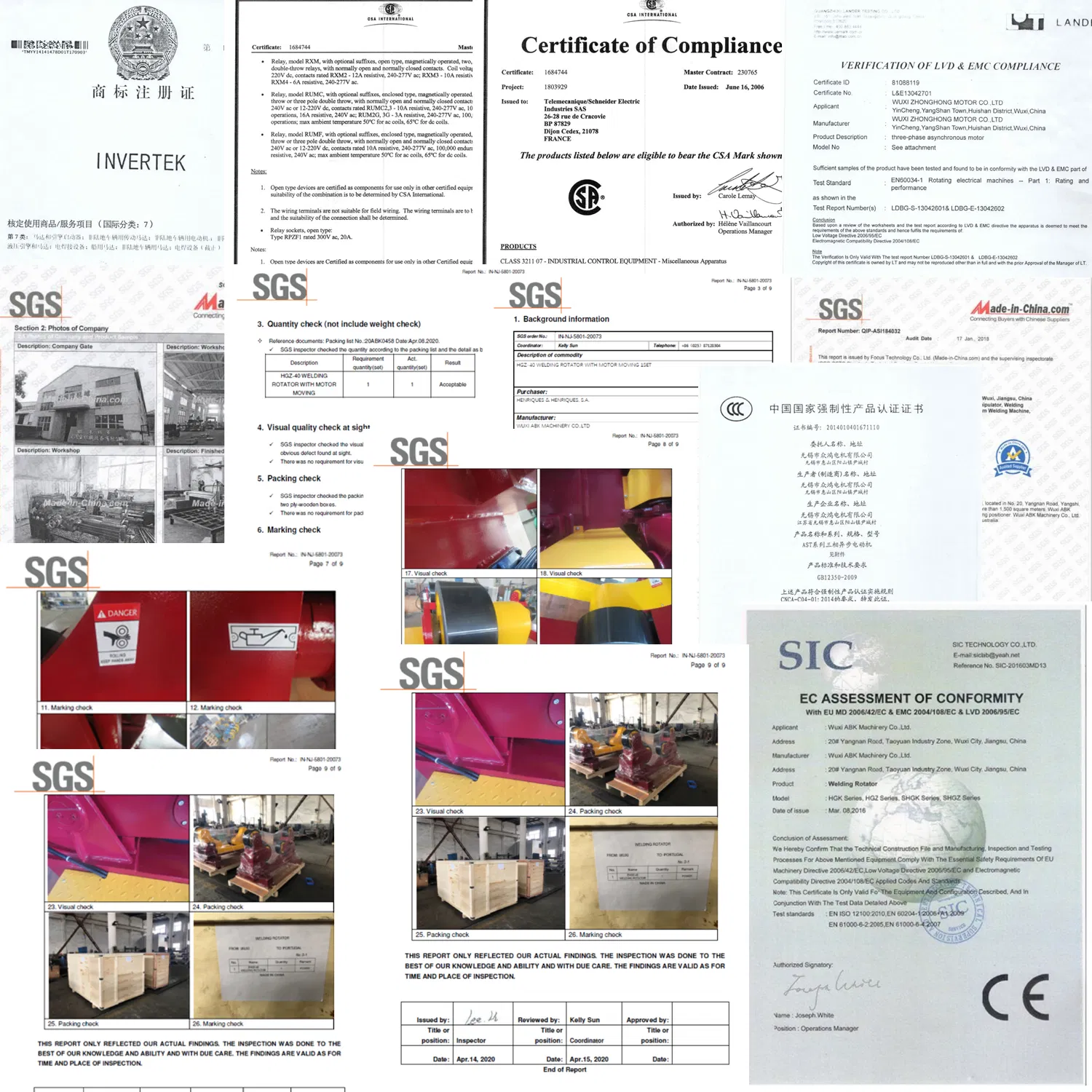

✓ Certified Quality: CE compliant | ISO 9001 certified

✓ Global Reliability: Exported to 20+ countries (UK, EU, Middle East, etc.)

Performance Features

• Ultra-stable rotation (<0.1mm runout)

• Low-noise operation (<65dB)

• User-friendly interface

Parameter list of conventional HGZ series welding rotator

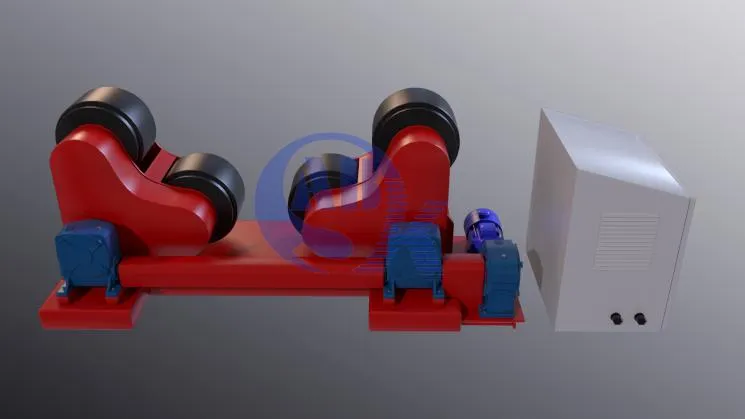

WUXI ABK 80-Ton Standard Welding Rotator – Industrial-Grade Rotation Solution

Engineered for heavy industrial applications, our 80-ton welding rotator delivers exceptional performance in изготовление сосудов под давлением, wind tower production, и ship component manufacturing. The robust box-type steel construction ensures optimal load distribution, while the precision linear guide system maintains ±0.1mm positioning accuracy – 40% better than conventional rotators.

Core Technical Advantages:

-

High-capacity rollers: ZG45 cast steel (HRC 55-60) with 30-ton/roller dynamic capacity

-

Smart drive system: Dual 7.5kW AC motors with 0.5-5 RPM stepless control (±2% torque sync)

-

Anti-creep technology: Hydraulic elevation (±50mm) with <0.5mm deviation

-

German precision: NOVO sensors (0.01mm resolution) and Siemens PLC control

Performance Benefits for Fabricators:

✓ 35% longer service life through premium components

✓ 50% faster adjustments with quick-lock mechanisms

✓ IP65 protection for harsh workshop environments

✓ Seamless integration with automated welding systems

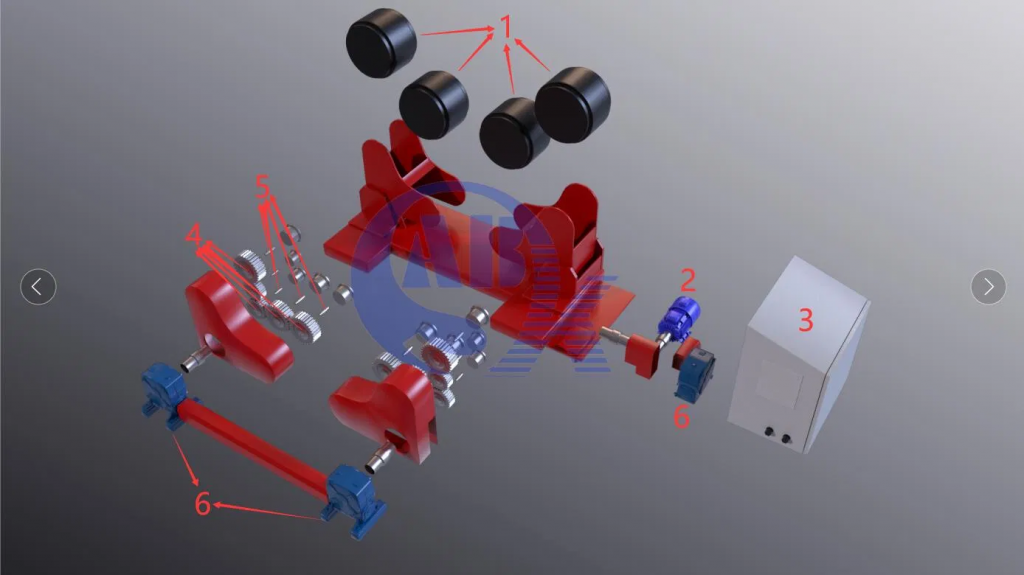

Features of Welding Rotator

1.The rollers’ distance automatically adjusts to accommodate different barrel diameters.

2.Speed is adjustable via a frequency control system, enhancing operational reliability.

3.Easy operation is ensured with a manual control box.

4.Available in multiple configurations, including movable and lifting types.

5.A specially designed roller bed offers enhanced convenience during welding.

6.Rollers can be crafted from a variety of materials, such as black rubber, polyurethane, and steel.

Maintenance of Welding Rotator

1. This welding rotator needs cleaning before putting into use. And to avoid aging, the rubber rollers should stay away from oils and high temperature. If possible, there should be a specific person to operate and maintain this device.

2. Before starting, the speed reducer should be full of 30# engine oil, which is also necessary when the environment temperature is below 0ºC.

3. The oil inside the speed reducer should be completely replaced after the use of first month, and later, the engine oil can be changed every six months.

4. The roller bed can not be used as the welding ground so that bearings can be prevented from damaging.

Product details

| · Trusted design | · Reliable Quality |

| · Renowned parts | · Inverter control |

| · Direct drive system | · Motorised travel option |

| · Build to order custom design | · OEM |

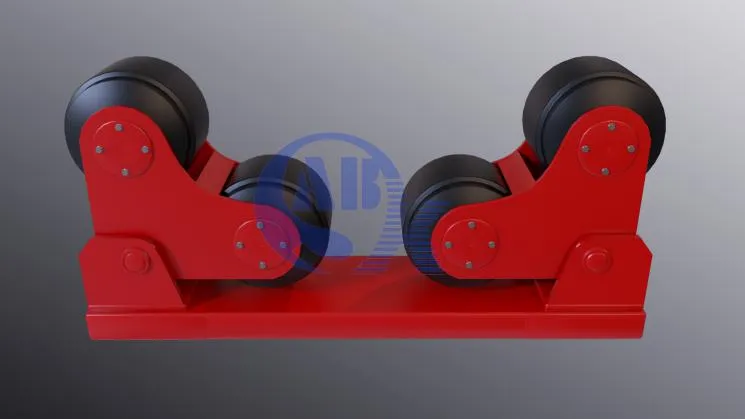

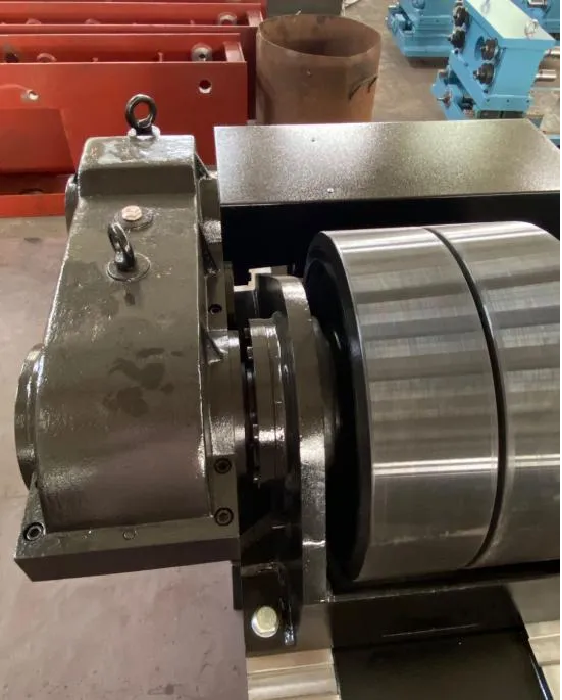

Wheel introduction

Polyurethane wheels offer exceptional abrasion resistance, versatile processing, wide applicability, and superior resistance to oil, ozone, aging, radiation, and low temperatures. They also provide strong adhesion, excellent sound transmission, biocompatibility, and blood compatibility.

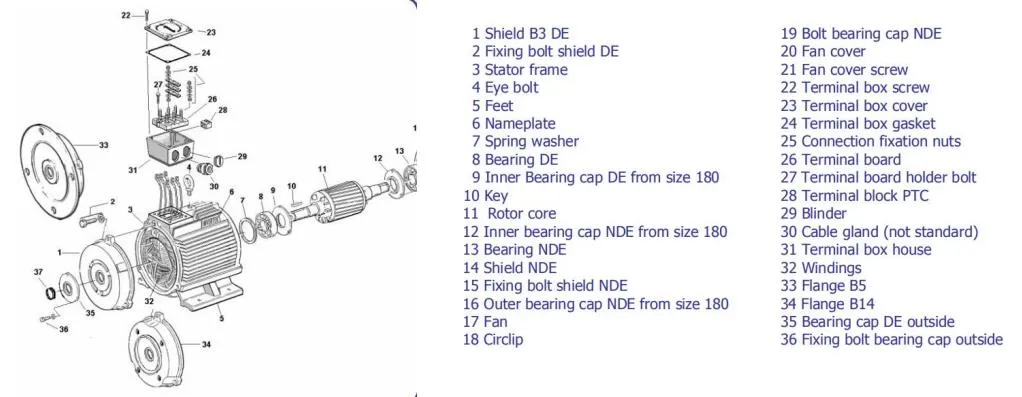

Motor introduction

With 20+ years of specialized expertise in self-aligning rotator manufacturing, WUXI ABK has established itself as a leading provider of heavy-duty welding positioners для изготовление сосудов под давлением, wind tower production, и shipbuilding applications. Наш industrial-grade rotators deliver unmatched performance with load capacities from 5 to 400 tons, designed to meet the most demanding автоматизация сварки requirements.

Why Choose WUXI ABK Rotators?

-

Certified Quality: All rotators are CE and ISO certified, ensuring compliance with international welding equipment standards

-

Reliable Performance: Featuring premium wear-resistant components с 1-year warranty и free wearing parts replacement

-

Technical Excellence: Our engineering support team provides customized solutions for large-scale projects including offshore wind turbine welding и petrochemical tank fabrication

Innovative Welding Technology

WUXI ABK integrates advanced automation и precision control systems into every rotator:

✓ Self-aligning roller technology for perfect workpiece centering

✓ Heavy-duty construction с 400-ton maximum capacity

✓ Smart interface compatibility for seamless welding cell integration

Компания Wuxi ABK Machinery Co.Ltd является профессиональным производителем сварочных вращателей в Китае. И наш сварочный вращатель в основном включает в себя стандартный сварочный вращатель, регулируемый сварочный вращатель и специальный сварочный вращатель. Мы также можем предоставить нашим клиентам по всему миру множество других продуктов, включая сварочный поворотный стол, сварочный аппарат для свай, линию для производства ветряных башен, линию для сварки двутавровых балок, оборудование для сварки труб, отрезной станок с ЧПУ, шлифовальный станок, роликовый формовочный станок, листогибочный станок и т.д. Мы получили сертификаты ISO и CE, а также предлагаем услуги OEM.