At the core of the energy, chemical and storage and transportation industries stand various huge storage tanks, which are the guardians of liquid raw materials, finished products and strategic reserves. The manufacturing quality of these storage tanks is directly related to operational safety and environmental protection. In this field where the requirements for Welding quality are almost exacting, the Posicionador de soldadura has become an indispensable manufacturing cornerstone. It is not merely a simple tooling, but a core equipment for enhancing the manufacturing level of storage tanks. This article will delve into the application of welding positioners in storage tank manufacturing, revealing how they help storage tank equipment manufacturers achieve more efficient and reliable welding quality through precise positioning and flipping, thus safeguarding the safety of infrastructure.

The Core Role of Welding Positioners in Tank Manufacturing

The tank manufacturing process is complex and rigorous, involving a significant amount of circumferential and longitudinal shell welds, as well as welds for attachments like nozzles and manways. These workpieces are typically massive and extremely heavy, posing a major challenge: how to achieve high-quality, uniform welding in all positions. Relying on traditional hoisting, flipping, or manual positioning not only carries significant safety risks but also makes it difficult to ensure welding accessibility and process consistency.

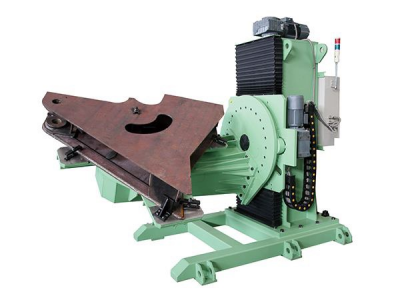

This is precisely where Welding Positioning Equipment excels. Its core function is to achieve precise positioning of the workpiece—that is, to rotate, tilt, or elevate tank components like shell courses and heads to the most ideal position as required by the welding operation. This allows welding operators or automated welding systems to always work in the most comfortable “flat” or “downhand” position, avoiding difficult positions like overhead or vertical welding, thereby significantly improving the stability and consistency of weld quality. For a Pressure Vessel Fabrication Plant striving for excellence, investing in high-performance positioners is a crucial step towards enhancing overall manufacturing capability.

Enhancing Weld Quality and Consistency

Weld quality is fundamental to the lifespan of a tank. The Tank Welding Positioner ensures the welding pool is always in the optimal position for formation through its stable rotation and precise speed control. This offers multiple benefits: stable rotation avoids common defects such as undercut, lack of penetration, or slag inclusion caused by unstable workpiece movement; constant travel speed results in consistent weld width and a uniform, aesthetic ripple pattern, which not only guarantees strength but also greatly enhances the weld’s fatigue and corrosion resistance—this is crucial for tanks storing corrosive media long-term; through preset rotation parameters, every girth or seam weld can be completed with the same speed and quality, standardizing the production process, which is vital for tank products that must meet stringent industry standards.

How Welding Positioners Optimize the Tank Manufacturing Process

Beyond improving quality at a specific point, the welding positioner acts as an “efficiency engine” for the entire tank manufacturing workflow. In modern pressure vessel factory production lines, welding positioners are often integrated with automated welding systems to form an efficient work cell.

Enabling Automated Integration

For large-scale tank production, automation is an inevitable trend. The core component of an Automated Welding System is the welding positioner. It acts as the “coordinated partner” to welding robots or automatic welding machines, receiving commands from the control system and moving in precise sync. For instance, when welding a longitudinal seam on a shell, the positioner can precisely adjust the workpiece angle to keep the weld in the optimal position while the welding torch travels automatically. This close coordination drastically reduces the welding cycle time and minimizes human intervention, forming the foundation for efficient, high-quality production.

Ensuring Operational Safety

Tank components like shell courses and heads are often massive and extremely heavy. Manually flipping or moving these workpieces poses significant safety risks. The design of a Heavy Duty Positioner prioritizes safety factors. Through robust mechanical structures and reliable locking mechanisms, it securely clamps the workpiece and performs positioning movements smoothly. This fundamentally prevents personal injury and equipment damage that could result from workpiece tipping or slipping, providing workers with a safe and reliable working environment.

Specific Application Scenarios for Welding Positioners in Tank Manufacturing

To understand the value of welding positioners more concretely, let’s examine several typical scenarios in tank manufacturing.

Girth and Longitudinal Seam Welding of Shells

This is the most common application. After steel plates are rolled into cylindrical shell courses, the longitudinal seam must be welded. Here, the shell course is fixed onto a Welding Positioner Machine. The positioner rotates the longitudinal seam into the optimal position for the automatic welding torch’s travel path. When multiple shell courses are aligned for circumferential welding, the positioner rotates the entire assembly at a uniform speed, completing the entire girth weld, ensuring both efficiency and quality.

Head and Nozzle Welding

Tank heads are typically hemispherical or dished shape. Welding various nozzles and manways onto them involves complex positions and limited space. Precision Welding Positioning becomes particularly critical here. The welding positioner can make fine angular adjustments to the head, bringing complex spatial welds into the best possible position, ensuring the reliability of these critical connection points.

Welding of Special Materials like Duplex Stainless Steel

In the chemical industry, many tanks are made from special materials like duplex stainless steel or nickel-based alloys, which are highly sensitive to welding heat input. The stable rotation speed of a Tank Welding Positioner ensures consistent heat input, avoiding microstructural degradation caused by speed fluctuations, making it key to the successful welding of tanks made from special materials.

Key Considerations for Selecting the Right Welding Positioner

Faced with a plethora of products on the market, how does one select a suitable welding positioner for tank manufacturing? This requires a comprehensive evaluation of multiple technical parameters and actual working conditions. A competent Welding Equipment Supplier should offer professional technical consultation to help clients make the optimal choice.

Load Capacity and Size Range

This is the most fundamental consideration. The positioner’s load capacity must cover the maximum weight of the tank components produced by the factory, including a safety margin. Simultaneously, the size range of its chucks or roller racks needs to accommodate shell courses from the smallest to the largest diameter. Selecting a Heavy Duty Positioner is particularly important for producing large-diameter tank shell courses.

Control Precision and Drive Type

The rotational accuracy of the positioner directly impacts welding quality. Systems typically driven by servo motors or frequency conversion motors offer smoother stepless speed regulation and more precise positional control. Precision Welding Positioning is a prerequisite for high-quality welds, making the stability and accuracy of the electrical control system a key evaluation point.

System Integration and Flexibility

An ideal welding positioner should possess good compatibility and scalability. It should easily communicate and integrate with existing welding robots, specialized welding machines, or Manufacturing Execution Systems. This kind of Advanced Manufacturing Solution forms the basis for building the smart factories of the future. Furthermore, the equipment should also possess a degree of flexibility to adapt to trends like high-mix, low-volume production.

Technological Innovation and Future Outlook for Welding Positioners

With the rapid development of smart manufacturing technologies, welding positioner technology is also continuously innovating and upgrading. Future Industrial Welding Positioners will become more intelligent and digital.

New generations of welding positioners are beginning to integrate intelligent control systems, using sensors to monitor equipment status in real-time for predictive maintenance. Some leading Welding Equipment Manufacturers have already developed positioners with adaptive control functions that can automatically adjust rotation speed based on welding process requirements, ensuring consistent weld quality.

Modular design has become another important trend. To adapt to the high-mix, low-volume production characteristics of tank manufacturing, modern welding positioners are adopting more modular designs, allowing for quick reconfiguration to meet the positioning needs of workpieces with varying diameters, lengths, and weights. This Flexible Manufacturing Solution helps tank manufacturing enterprises better respond to market changes.

Return on Investment Analysis for Welding Positioners

For tank manufacturing enterprises, investing in a welding positioner is not only about improving product quality but also a rational decision based on economic benefits. A high-performance Tank Welding Positioner can create value for the enterprise in several aspects.

The improvement in weld quality directly reduces rework and scrap rates, saving significant material costs and time costs. The shortened production cycle enables the enterprise to take on more orders, enhancing market competitiveness. Additionally, increased automation reduces dependence on highly skilled welders, alleviating labor pressure. These factors together constitute the return on investment for a welding positioner, typically allowing the investment cost to be recovered in a relatively short period.

Conclusion

In the critical field of tank manufacturing, which is vital to the national economy and livelihood, the pursuit of precision engineering is endless. The Posicionador de soldadura, as a key piece of equipment supporting the core process of welding, offers value far beyond simply “rotating a workpiece.” It is a central force in enhancing weld quality, optimizing production workflows, ensuring operational safety, and driving automation upgrades. For any Tank Equipment Manufacturer aiming to maintain competitiveness in the industry, selecting the right Welding Equipment Supplier and investing in advanced, reliable Welding Positioning Equipment is undoubtedly a strategic decision with foresight. It ultimately translates into stronger, safer tank facilities, contributing an indispensable force to the steady development of the energy and chemical industries.

Welding Equipment Supplier:

Tank Equipment Manufacturer:

https://www.weldmc.com/product-category/welding-automation

Welding Positioning Equipment:

https://www.weldmc.com/product-category/welding-automation/welding-positioner

Tank Welding Positioner:

Industrial Welding Positioners:

Precision Welding Positioning: