40Tons Fit Up Rotator

The WUXI ABK 40-Ton Fit Up Rotator is a heavy-duty welding positioner engineered for precision vessel fabrication, featuring hydraulic alignment with ±0.5mm accuracy and stepless speed control from 0.1-1.2m/min. Designed for 1.5-6m diameter workpieces with 50-ton capacity, this robust system incorporates safety mechanisms and seamless welding manipulator integration to optimize pressure vessel and pipeline girth welding operations in demanding industrial environments.

40 Tons Fit Up Rotator

CONVENTIONAL WELDING ROTATORS

FIT UP Series

Conventional Rotators are designed to aid in the welding of cylindrical vessels or columns.

| · Trusted design | · Reliable Quality |

| · Renowned parts | · Inverter control |

| · Direct drive system | · Motorised travel option |

| · Build to order custom design | · OEM

|

CONVENTIONAL WELDING ROTATORS

FIT UP Series

Conventional Rotators are designed to aid in the welding of cylindrical vessels or columns.

| · Trusted design | · Reliable Quality |

| · Renowned parts | · Inverter control |

| · Direct drive system | · Motorised travel option |

| · Build to order custom design | · OEM |

- Summary

- Equipment composition

Core Components & Functionality

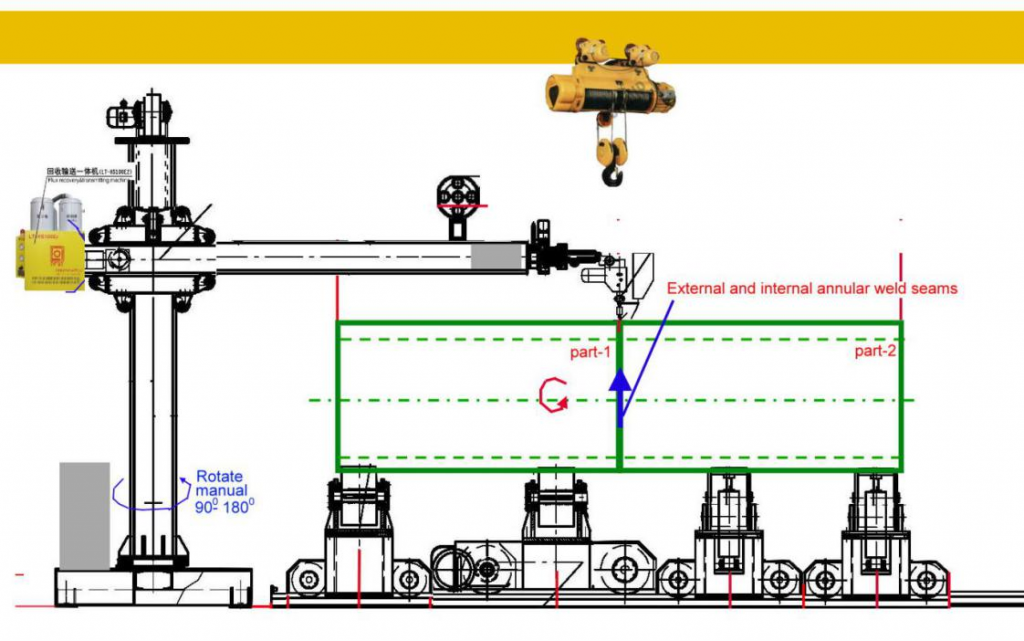

The WUXI ABK 40-Ton Fit Up Rotator is a precision-engineered system designed for large-diameter vessel fabrication, pipeline girth welding, and offshore structure assembly. Its robust configuration includes:

-

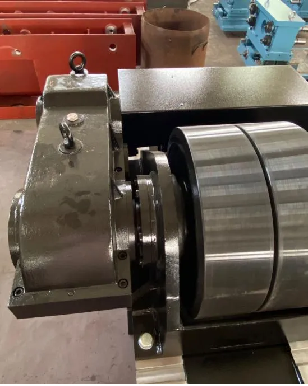

Driving roller frame with AC motor + reducer and frequency conversion control (0.1–1.2m/min adjustable speed)

-

Driven roller frame y hydraulic assembly rollers (2 sets) with 0.5mm alignment accuracy

-

Integrated hydraulic lifting y track movement for seamless cylinder butt-jointing

Workflow Efficiency

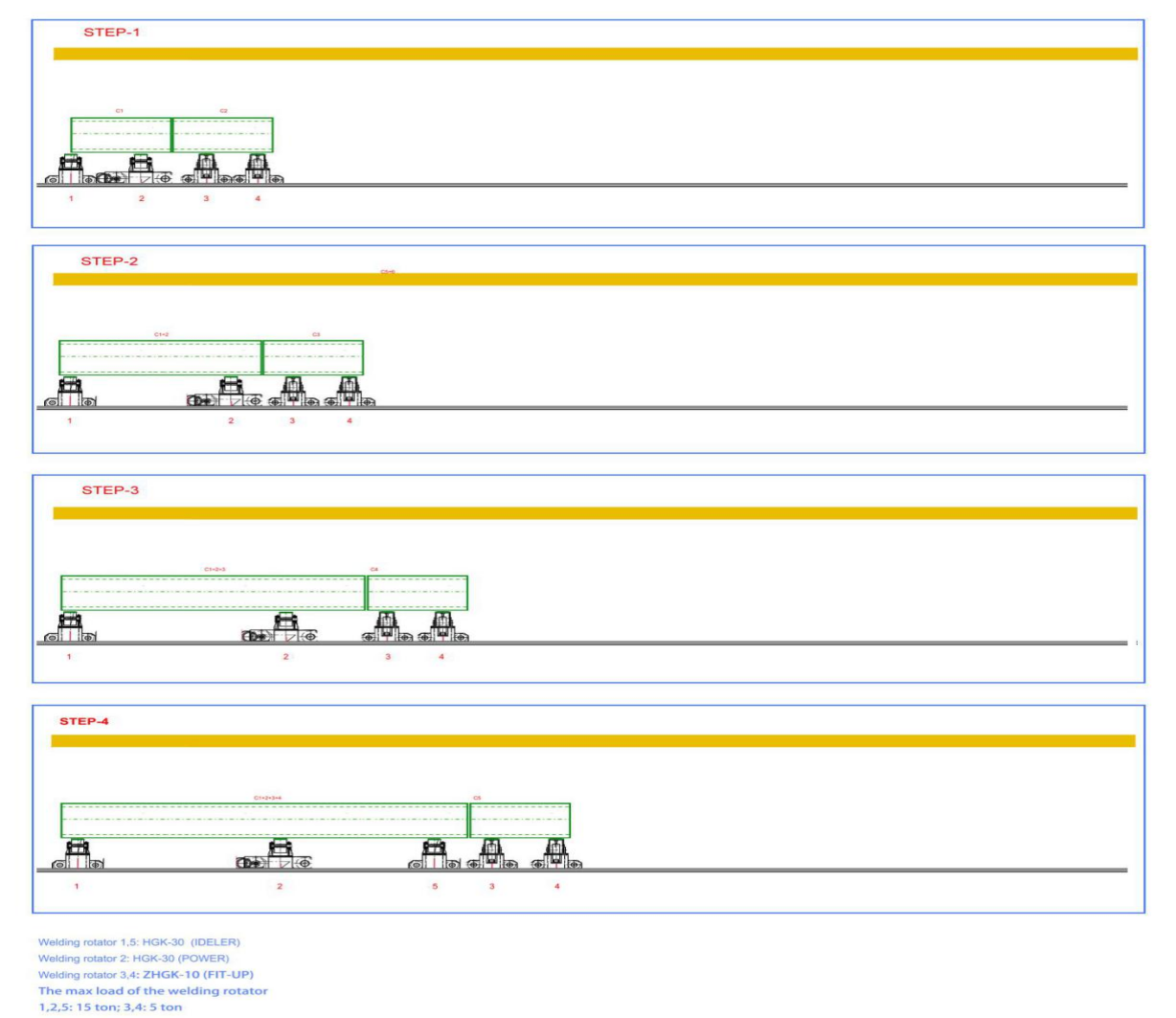

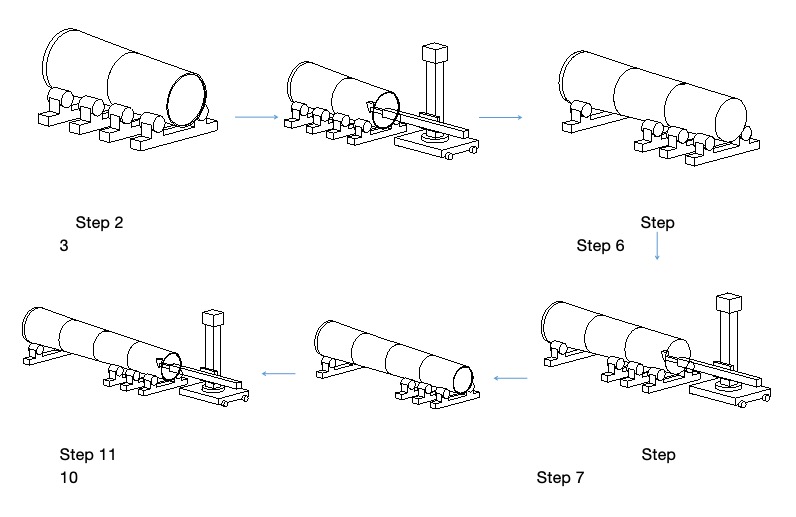

This industrial rotator streamlines pressure vessel welding y wind tower fabrication through a three-stage process:

-

Segmented Positioning: Place cylinders on driving/driven frames; align via hydraulic adjustment.

-

Assembly & Welding: Achieve precision fit-up (±0.5mm); weld inner/outer seams using welding manipulators.

-

Continuous Expansion: Repeat to complete large-scale container welding (1.5–6m diameter).

Technical Advantages

-

50-ton max load (customizable for heavy fabrication)

-

Stepless speed regulation para consistent weld quality

-

Anti-creep y anti-deflection mechanisms

-

Automated welding integration (compatible with robotic welding systems)

Safety & Compliance

-

Overload protection y emergency braking

-

ASME-compliant welding processes

-

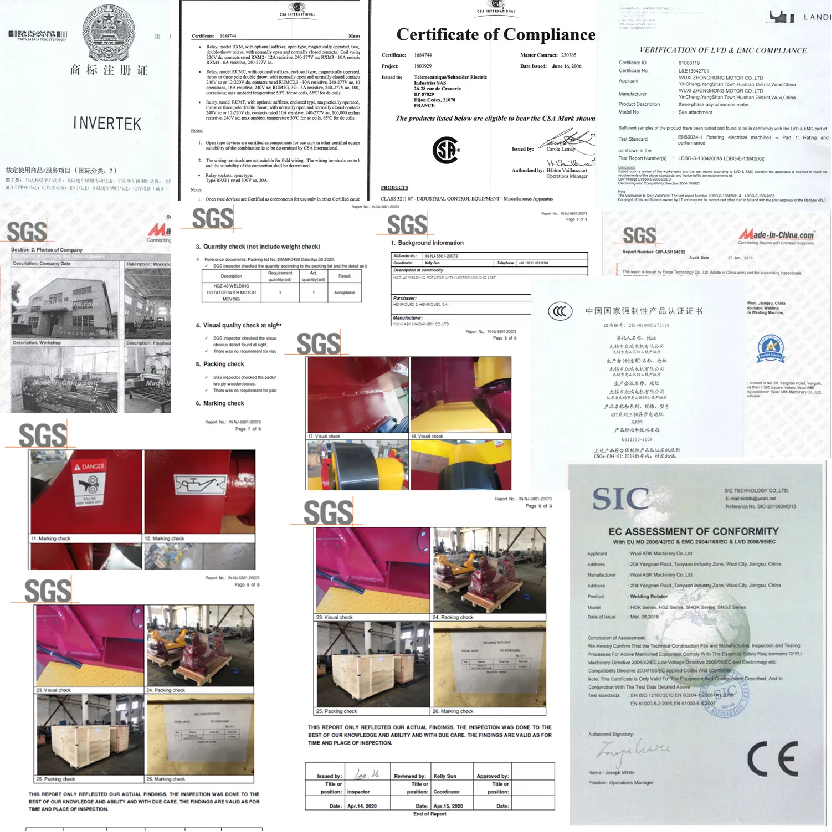

CE/ISO certified para industrial safety

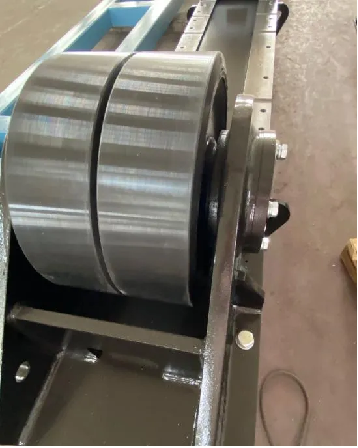

Wheel introduction

Polyurethane wheels offer exceptional abrasion resistance, versatile processing, wide applicability, and superior resistance to oil, ozone, aging, radiation, and low temperatures. They also provide strong adhesion, excellent sound transmission, biocompatibility, and blood compatibility.

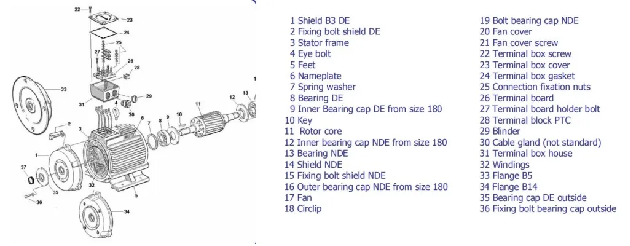

Motor introduction

Welding Rotator Maintenance Guidelines

Clean the welding rotator before use. Keep the rubber rollers away from oils and high temperatures to prevent aging. It’s recommended that a designated person operates and maintains the equipment.

Ensure the speed reducer is filled with 30# engine oil before starting, especially when the temperature is below 0ºC.

Replace the oil in the speed reducer after the first month of use. Afterward, change the oil every six months.

Do not use the roller bed as a welding ground to avoid damaging the bearings.

Top quality rotator manufacturer

1.With over 20 years of specialized experience in manufacturing self-aligning rotators.

2.Our products feature a bearing capacity that ranges from 5 tons to 400 tons.

3.We provide CE and ISO certifications, ensuring compliance with stringent sub-regulations. Additionally.

4.We offer a one-year warranty and free wearing parts.

5.Our highly skilled technical team is dedicated to supporting you and your large-scale projects, such as wind turbine welding.

Wuxi ABK Machinery Co.Ltd es un fabricante profesional de rotador de soldadura en China. Y nuestro rotador de soldadura incluye principalmente rotador de soldadura estándar, rotador de soldadura ajustable y rotador de soldadura especial. También podemos ofrecer a nuestros clientes en todo el mundo muchos otros productos, incluyendo la plataforma giratoria de soldadura, máquina de soldadura de pilotes, línea de producción de torres eólicas, línea de soldadura de vigas H, equipos de soldadura de tuberías, máquina de corte CNC, máquina rectificadora, máquina perfiladora, máquina curvadora de placas, etc. Hemos obtenido la certificación ISO y CE, y también ofrecemos servicio OEM.