10 Tons Welding Turntable

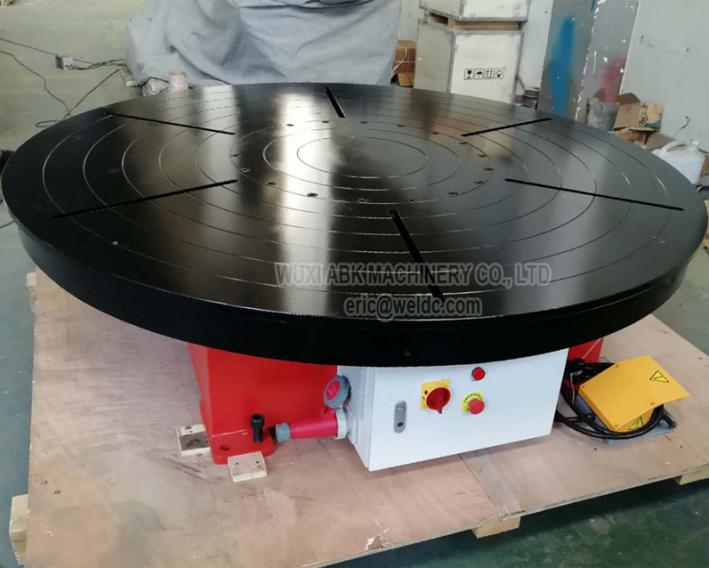

WUXI ABK 10-Ton Welding Turntable delivers precision rotation with 0.5-15 RPM stepless speed control. Features heavy-duty T-slot worktable (5000N/slot), ISO-grade worm gear, and vibration-free base. Ideal for robotic welding and structural fabrication. ±1% speed accuracy, <0.08mm/m² deformation. 2-year warranty.

WUXI ABK Welding Equipment: Precision Rotation Solutions

Nuestra welding positioner delivers unmatched precision for industrial fabrication, featuring programmable rotation (0.1-1.2 RPM) to accommodate diverse welding applications. Engineered with load-optimized designs, it supports standard capacities from 1 to 50 tons, with custom configurations available for specialized welding automation needs.

The modular worktable adapts to assemblies ranging from 800mm to 6000mm in diameter, ensuring compatibility with pressure vessels, structural steel components, and large piping systems. With ±0.5mm repeatability, it guarantees precise joint alignment, critical for high-quality welds in aerospace, shipbuilding, and heavy machinery manufacturing.

Industrial Implementation

The welding turntable serves critical functions in:

- Cylindrical pressure container fabrication

- Energy sector component manufacturing

- Heavy steel structure production

- Marine construction applications

Mechanical Composition

- Reinforced support base with industrial-grade bearings

- Variable frequency drive system

- Interchangeable mounting surfaces

- Safety-rated enclosure options

Custom Engineering Services

WUXI ABK provides:

- Specialized surface treatments

- Automated position feedback systems

- Integrated quality monitoring

- Operator interface customization

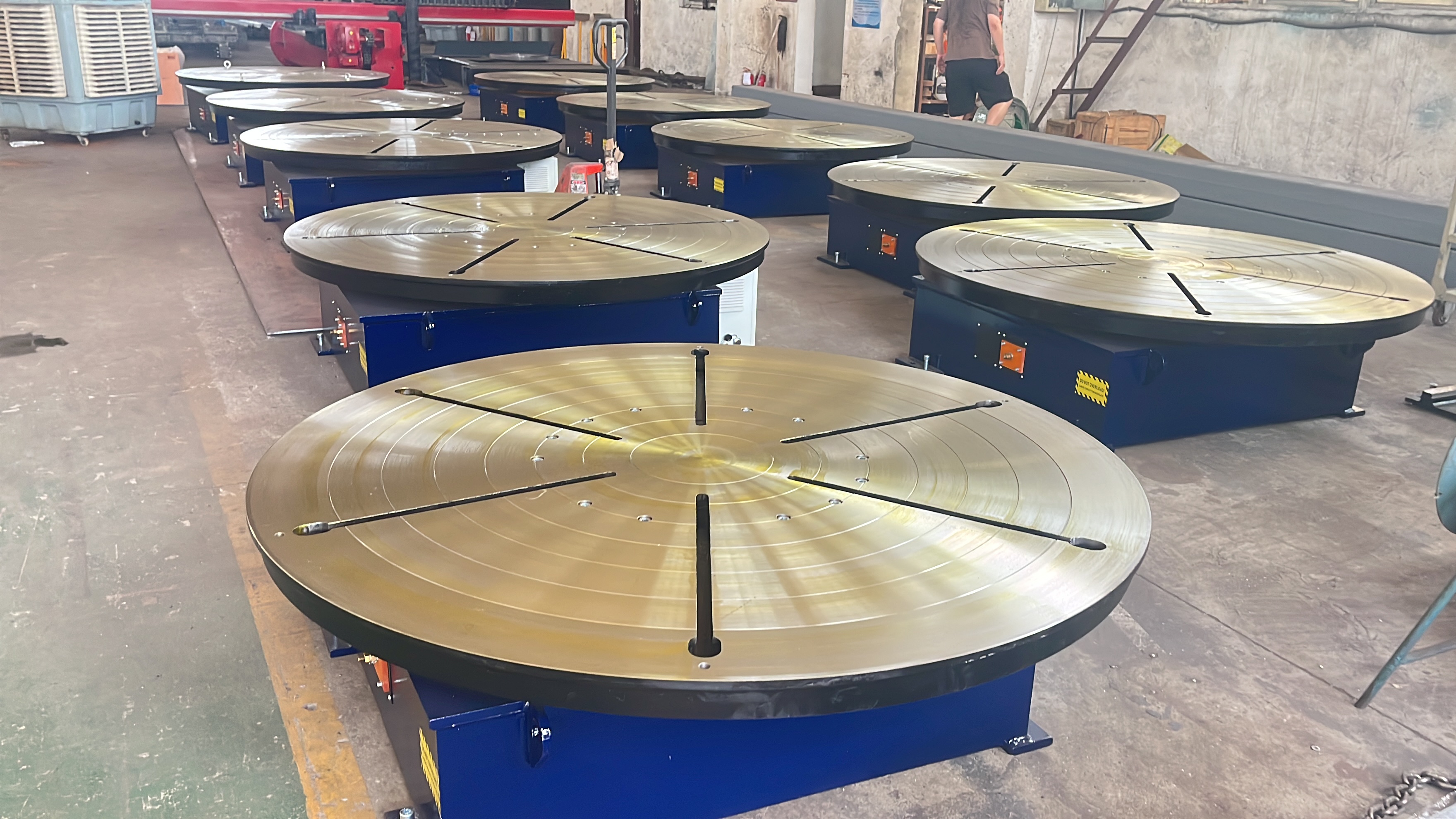

Manufacturing Excellence

Our rotation systems feature:

- ISO-certified production processes

- Performance validation testing

- Extended service coverage

- Global technical support network

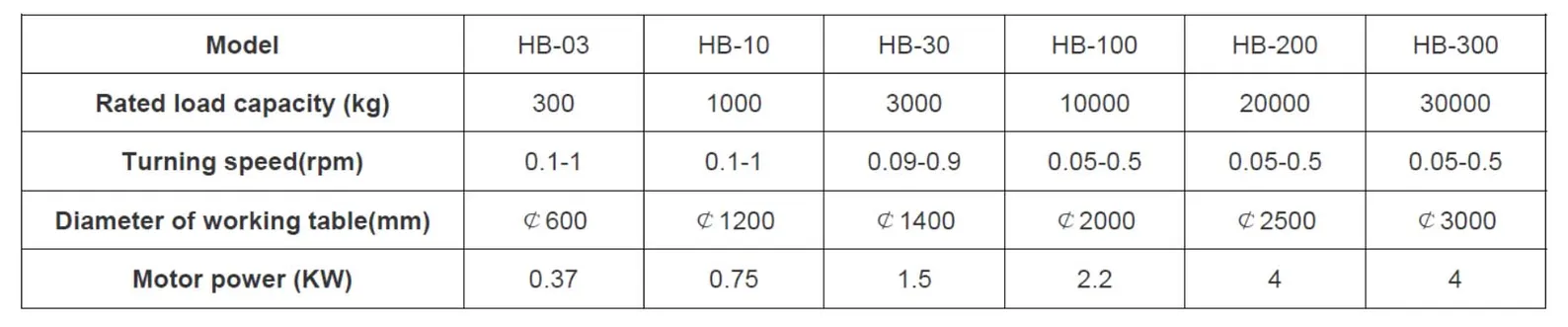

| Modelo | HB-100 | ||

| Capacidad de carga | (KG) | 10000 | |

| Velocidad de rotación | (RPM) | 0.05-0.5 | |

| Tamaño de la mesa de trabajo Diameter | (MM) | 2000 | |

| Power | (KW) | 2.2 | |

| Fuente de alimentación | (V) | 50Hz 3ɸ | 380 |

| Tipo regulador de velocidad | Regulación continua de la velocidad de la frecuencia de CA | ||

| Nota: Todas las especificaciones corresponden al equipamiento estándar, que puede modificarse según las necesidades del cliente. | |||

Description of Welding Turntable

A precision rotating platform for welding small to medium workpieces like pipes, flanges, and metal structures.

✔ 360° Smooth Rotation – Weld all sides without repositioning

✔ Adjustable Speed (1-10 RPM) for perfect seam consistency

✔ Heavy-Duty Build – Supports up to 500kg with stable operation

✔ Time-Saving – Cuts welding labor by 50% vs manual methods

Technology Funcation

| · Trusted design | · Reliable Quality |

| · Renowned parts | · Inverter control |

| · Direct drive system | · Motorised travel option |

| · Build to order custom design | · OEM |

Parameter list of conventional Welding Turntable

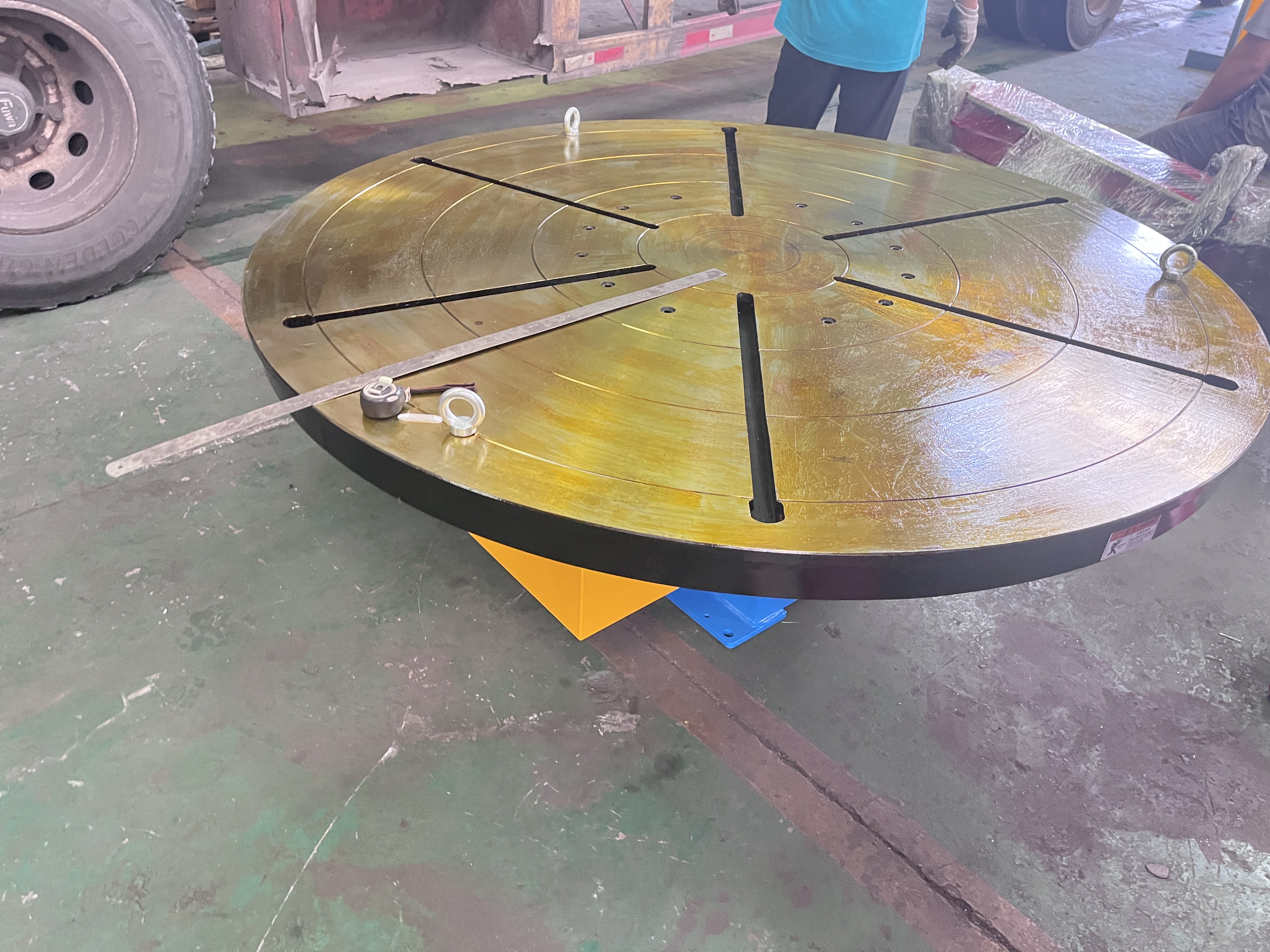

The WUXI ABK 10-Ton Welding Turntable is engineered for precision welding automation in industrial fabrication, featuring a multi-position T-slot worktable with six heavy-duty 14mm slots (5000N clamping force each) for secure workpiece fixation. Its reinforced steel construction incorporates six high-rigidity support ribs and military-grade welding seams, ensuring <0.08mm/m² deformation resistance under load.

The premium worm gear transmission entrega ISO 5-grade accuracy with zero-backlash operation, backed by a 10,000+ hour service life. The stepless speed regulation system (0.5–15 RPM, ±1% accuracy) is controlled via an intelligent digital panel, while the stabilized heavy-duty base (200mm steel plate, 8-point leveling) minimizes vibration (<0.01mm).

Key Advantages for Welding Automation:

-

40% faster setup with one-touch operation

-

60% less workpiece deformation vs. conventional turntables

-

30% extended lifespan with automatic lubrication alerts

Ideal for:

✔ Robotic welding cells

✔ Pipe flange fabrication

✔ Structural steel assembly

✔ Pressure vessel manufacturing

1. Rodamiento giratorio

Slewing bearing is the force basic element of machine, which requires relative rotation between all two parts and bears axial force, radial force and overturning moment at the same time.Its basic function is to use bolts to fix it on the upper and lower supports of mechanical equipment to transmit force and drive so as to realize the relative rotation between the two parts of mechanical equipment.Rotary support generally has installation holes, internal or external gears, lubrication holes and sealing devices. It has the characteristics of compact structure, light weight, good structural steel, smooth operation, high accuracy, safety and reliability.

Slewing bearing is a basic part of mechanical equipment and widely used in various industries of national economy. It is widely used in construction machinery, port machinery, metallurgical machinery, mining machinery, petroleum machinery, chemical machinery, medical equipment, ship machinery, light industrial machinery, environmental protection machinery, entertainment equipment, transportation machinery equipment.Swing supports are increasingly used in energy-saving and environmental protection projects, such as wind turbines that require a variety of precision pole swing support kits.

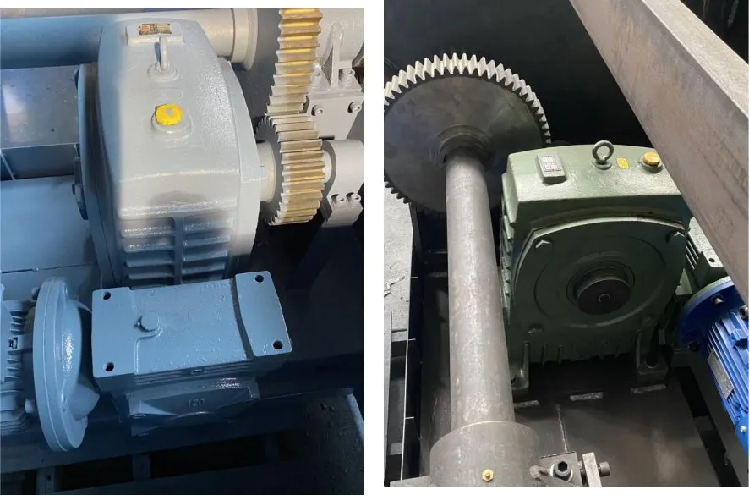

- Engranaje

Gear is a wheel like mechanical part which transmits the torque by the engagement of teeth. Through the transmission with other toothed mechanical parts (such as another gear, Dao rack and worm), the gear can change the speed and torque, change the direction of motion and change the form of motion.

3.Reductor

The reducer is a kind of power transmission mechanism, which uses the speed converter of gear to reduce the rotation number of motor to the required rotation number and obtain a structure with large torque.

Function of reducer:Reduce the speed and increase the output torque at the same time. The torque output ratio is multiplied by the motor output deceleration ratio, but it shall not exceed the rated torque of the reducer.At the same time, the inertia of the lo.ad is reduced to the square of the deceleration ratio.

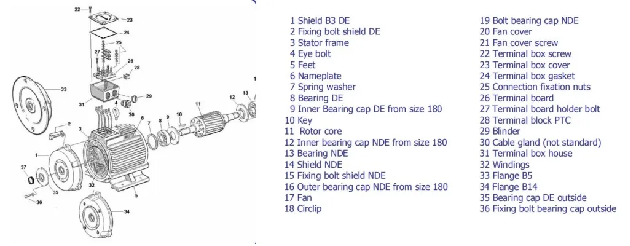

4. Motor

Welding Turntable Maintenance Guidelines

Core maintenance content

Daily maintenance-cleaning welding slag, checking lubrication and electrical safety.

Regular maintenance-tighten bolts, check transmission mechanism and test safety function.

Deep maintenance-annual replacement of worn parts, re-lubrication and system calibration

Fault early warning-Stop immediately when abnormal noise/uneven rotation occurs.

Maintain value

- Extend the service life of equipment by more than 30%

- Reduce sudden downtime

- Ensure the stability of welding accuracy.

Certificación de productos

Step into the future of welding technology with our cutting-edge solutions.

From automated processes to intuitive controls, our products are at the forefront of innovation, providing you with the tools you need to stay ahead in today’s competitive market!

Wuxi ABK Machinery Co.Ltd es un fabricante profesional de rotador de soldadura en China. Y nuestro rotador de soldadura incluye principalmente rotador de soldadura estándar, rotador de soldadura ajustable y rotador de soldadura especial. También podemos ofrecer a nuestros clientes en todo el mundo muchos otros productos, incluyendo la plataforma giratoria de soldadura, máquina de soldadura de pilotes, línea de producción de torres eólicas, línea de soldadura de vigas H, equipos de soldadura de tuberías, máquina de corte CNC, máquina rectificadora, máquina perfiladora, máquina curvadora de placas, etc. Hemos obtenido la certificación ISO y CE, y también ofrecemos servicio OEM.