Línea de soldadura de torres eólicas

WUXI ABK Wind Tower Welding Line delivers automated precision for tower section fabrication, featuring robotic girth welding y flange alignment systems. Our CNC-controlled positioners ensure ±1mm accuracy for large-diameter joints, while the integrated seam tracking maintains consistent weld penetration. Ideal for 4-8MW turbine towers, this CE-certified line boosts productivity by 40% with smart process monitoring.

Core characteristics

- Efficient cantilever workstation

- Modular cantilever structure design, supporting multi-station combination

- Multi-layer and multi-pass continuous welding can be realized, and the efficiency is improved by more than 50%.

- Full-process integrated system

- Comprises a plate bending machine, a numerical control cutting machine, welding equipment, a welding displacement unit and a sand blasting and painting rotary roller.

- All units cooperate to realize the complete processing of tower from plate to finished product.

- EIntelligent welding control

- Digitally adjust welding parameters to ensure the consistency of girth welding.

- Adapt to towers with different diameters (2.5m-6m).

Typical configuration

- Pretreatment unit: CNC cutting and blanking

- Forming unit:three-roll plate bending machine

- Welding unit:cantilever submerged arc welding system (including dust removal device)

- Post-processing unit: sandblasting and derusting+automatic painting turntable

Industrial application

It is suitable for mass manufacturing of 2MW-8MW onshore/offshore wind turbine towers, and is compatible with carbon steel/high strength steel materials.

WUXI ABK Wind Tower Welding Line Technical Solution

Precision Blanking Process for Conical Tower Sections

Nuestra wind tower production line implements strict dimensional control for conical single-section fabrication, where upper and lower diameter tolerances are critical. The automatic blanking system maintains ±1.5mm precision on main steel plates using laser-guided feeding technology, essential for ensuring subsequent circular seam welding quality. This process is supported by our CNC cutting equipment with real-time thickness compensation.

Flange Welding Deformation Control

To address flange distortion challenges in wind turbine tower manufacturing, we deploy:

-

Segmented symmetrical welding technology with our SAW (Submerged Arc Welding) systems

-

Automatic circular seam straighteners featuring hydraulic pressure up to 300 tons

-

Post-weld heat treatment stations for stress relief

These solutions reduce flange runout to <2mm/m, exceeding EN 1090-2 standards for offshore wind tower fabrication.

Tower Section Assembly Optimization

For long-section towers (12-30m), our production line integrates:

-

Laser centering systems with ±0.5mm alignment accuracy

-

Digital pre-assembly platforms that boost efficiency by 40%

-

Automated clamping fixtures para flange-to-shell matching

The welding positioners y rotators in our line accommodate diameters up to 6m, while adaptive welding tractors ensure consistent girth weld quality throughout the tower section rolling process.

Key Technologies & Equipment

✓ Robotic welding cells for longitudinal seams

✓ 3D scanning systems for dimensional verification

✓ Smart welding parameter database with 100+ preset programs

✓ Turnkey production solutions from blanking to final inspection

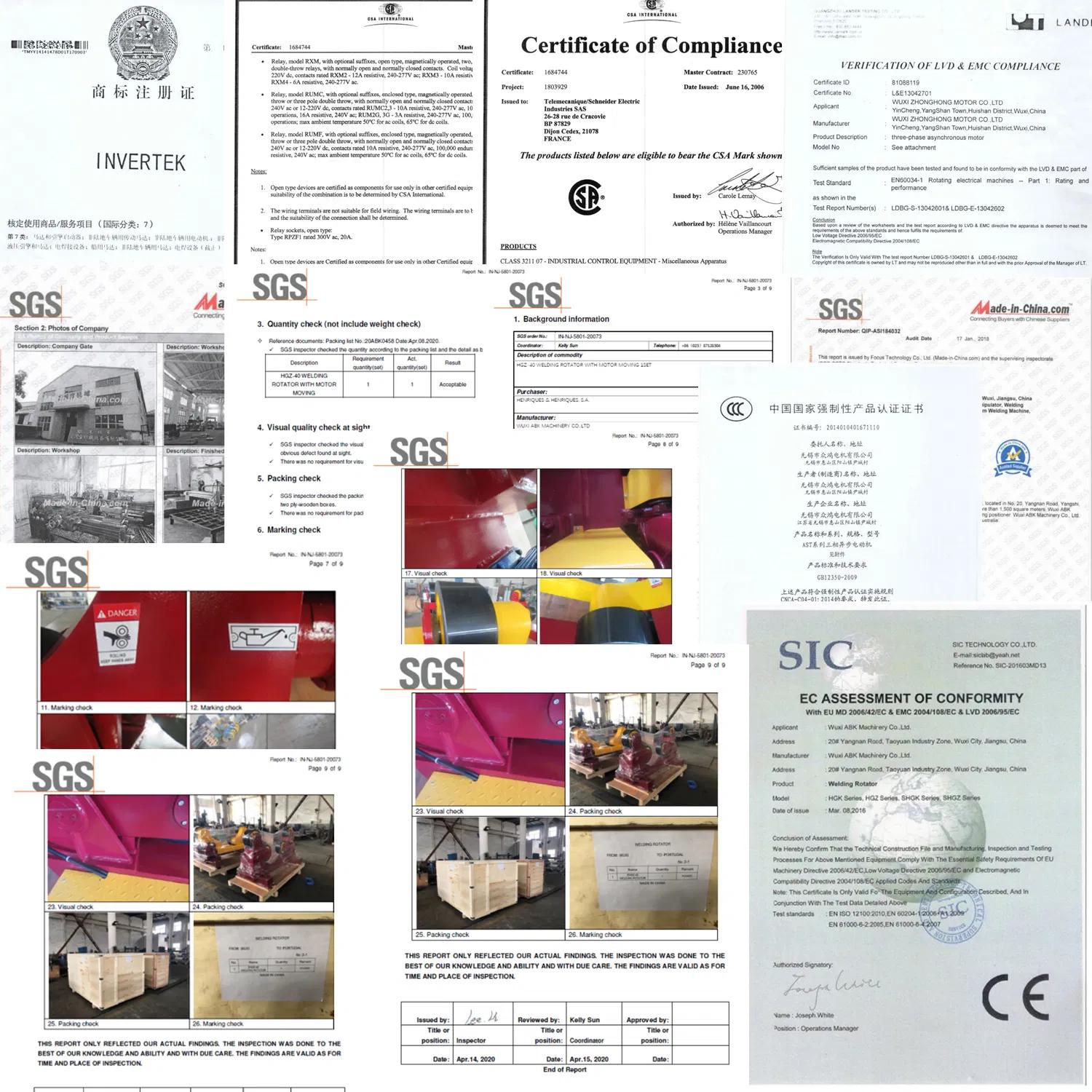

Quality Assurance

All systems comply with:

- GL Certification for wind energy components

- ISO 3834-2 welding quality standards

- CE Machinery Directive requirements

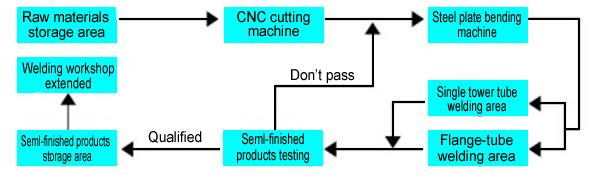

Single Tower Tube Production Process:

Multiple Tower Tubes Production Process:

Tower Tube Sandblasting and Painting Production Process:

Main Components of Wind Tower Welding Line:

1.Bending Machine:

2.Línea de soldadura de torres eólicas CNC Cutting Machine:

There are two kinds of CNC cutters for you to choose: CNC flame cutting machine and CNC plasma cutting machine, and both of them can simultaneously cut several plates, so the cutter is highly efficient.

- Welding Equipment:

The welding equipment mainly consists of welding manipulator, submerged-arc welding system, automatic recycling feeding system, and welding rotator.

4.Welding Rotator Set:

The matching part and circular seam welding section of the wind tower tube are mainly made up of welding manipulator, submerged arc welding system, automatic recycling feeding system, welding rotator.

5.Sandblasting and Painting

Turning rolls, with walking ability, are fitted to facilitate the sandblasting and painting process of the tower tubes. The painting turning rolls have adopted middle-concave roller wheels, which can be used to support flanges so that painting work can be finished conveniently. The motor is anti-explosive and dust-proof.

Wuxi ABK Machinery Co.Ltd es un fabricante profesional de rotador de soldadura en China. Y nuestro rotador de soldadura incluye principalmente rotador de soldadura estándar, rotador de soldadura ajustable y rotador de soldadura especial. También podemos ofrecer a nuestros clientes en todo el mundo muchos otros productos, incluyendo la plataforma giratoria de soldadura, máquina de soldadura de pilotes, línea de producción de torres eólicas, línea de soldadura de vigas H, equipos de soldadura de tuberías, máquina de corte CNC, máquina rectificadora, máquina perfiladora, máquina curvadora de placas, etc. Hemos obtenido la certificación ISO y CE, y también ofrecemos servicio OEM.